Measurement method and device of heat conductivity coefficients

A technology of thermal conductivity and measurement method, which is applied in the field of thermal conductivity material measurement, can solve the problems of inability to evaluate the thermal conductivity of products, consume a lot of time and cost, and achieve the effect of low requirements, low measurement cost and good data reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

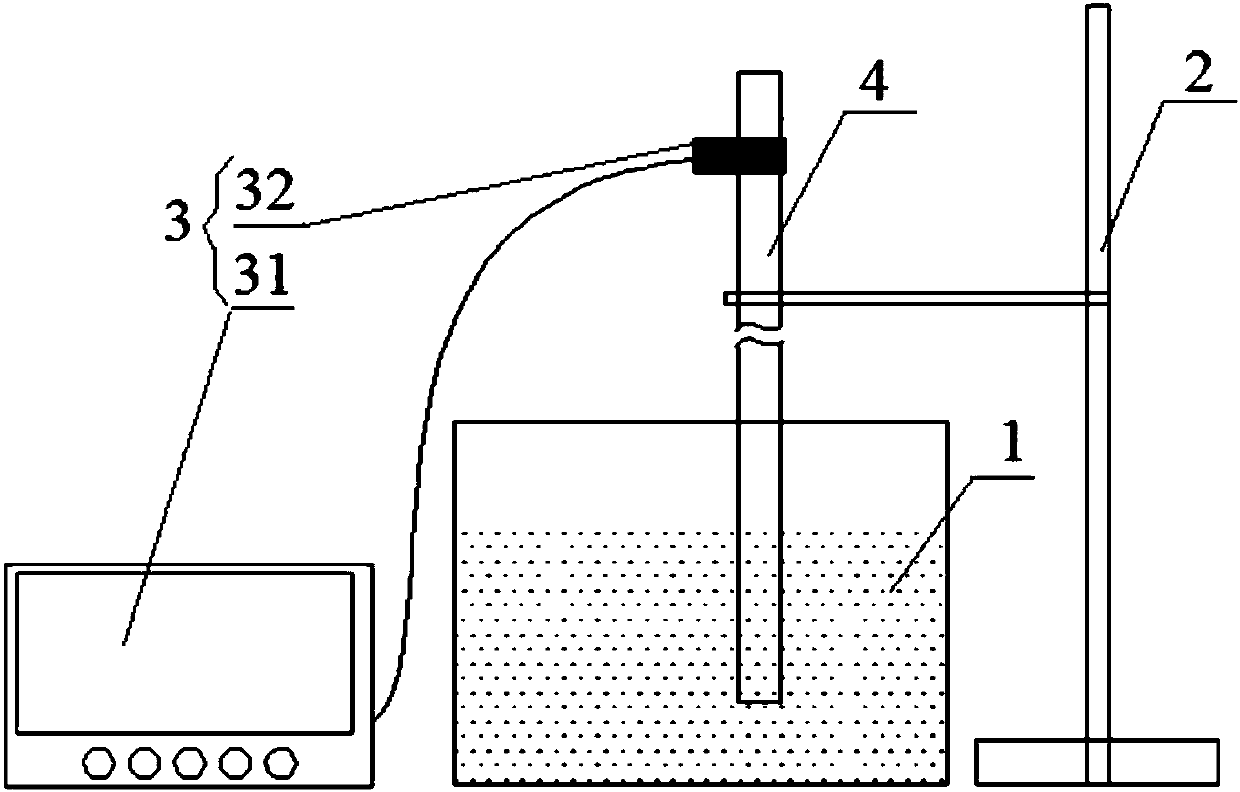

Method used

Image

Examples

Embodiment 1 to 3

[0044] (1) Preparation of the sample to be tested:

[0045] Select pure aluminum, pure magnesium, master alloy Al-50wt%Cu, Al-20wt%Si, Al-10wt%Mn as raw materials, and adopt conventional aluminum alloy ingot smelting methods to prepare alloy castings with the components and contents in Table 1. The ingot is prepared by die-casting method to prepare rectangular samples 1-3 with a length, width and height of 3×12.5×100 mm.

[0046] Table 1.

[0047] Sample to be tested

Al(wt%)

Si (wt%)

Cu(wt%)

Mg(wt%)

Mn(wt%)

1

margin

9

0.5

0.5

\

2

margin

8

\

0.5

\

3

margin

11

1

0.5

0.5

[0048] (2) The construction method of "time difference-thermal conductivity standard curve" is as follows:

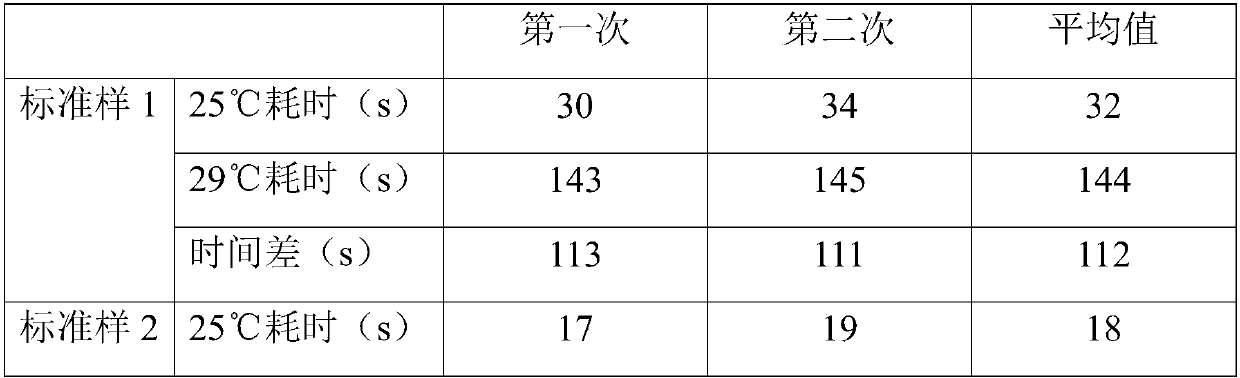

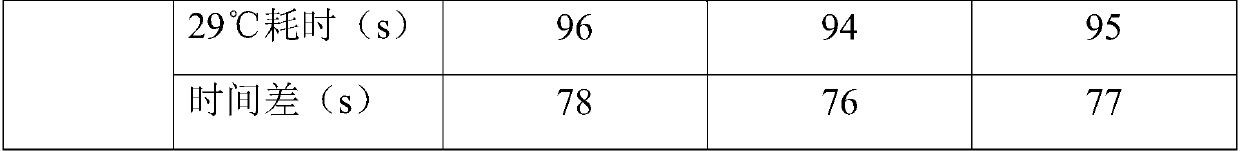

[0049] The water temperature in the water bath heating pot in the aforementioned thermal conductivity measuring device is heated to 50°C, and then the standard sample is fixed by the test sample fixing part, so that one end of the standard sample extends to the fixed position in the water bath heating pot...

Embodiment 4 to 6

[0059] (1) Preparation of samples to be tested: Referring to Examples 1-3, prepare rectangular samples to be tested 4-6 with a length, width and height of 3×12.5×100mm. The components and contents of each sample to be tested are shown in Table 4. .

[0060] Table 4.

[0061] Sample to be tested

Al(wt%)

Si (wt%)

Cu(wt%)

Mg(wt%)

Mn(wt%)

4

margin

7

\

0.5

\

5

margin

10

1

\

\

6

margin

11

2

0.5

0.2

[0062] (2) The construction method of "time difference-thermal conductivity standard curve" is as follows:

[0063] Heat the water temperature in the water bath heating pot in the aforementioned thermal conductivity measuring device to 60°C, and then fix the standard sample through the test sample fixing part so that one end extends to the fixed position in the water bath heating pot; set from one end of the standard sample Start timing in the water bath heating pot and record the corresponding time when the other end of the standard reaches 25°C and 29°C. After the test is complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com