Liquid absorbing core and supporting column integrated structure flat plate heat pipe based on carbon nano tube array

A carbon nanotube array and carbon nanotube technology, applied in the field of heat transfer, can solve the problems affecting the heat transfer performance of heat pipes, large liquid flow resistance, large steam channel size, etc., to achieve enhanced heat transfer performance, small liquid return velocity, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

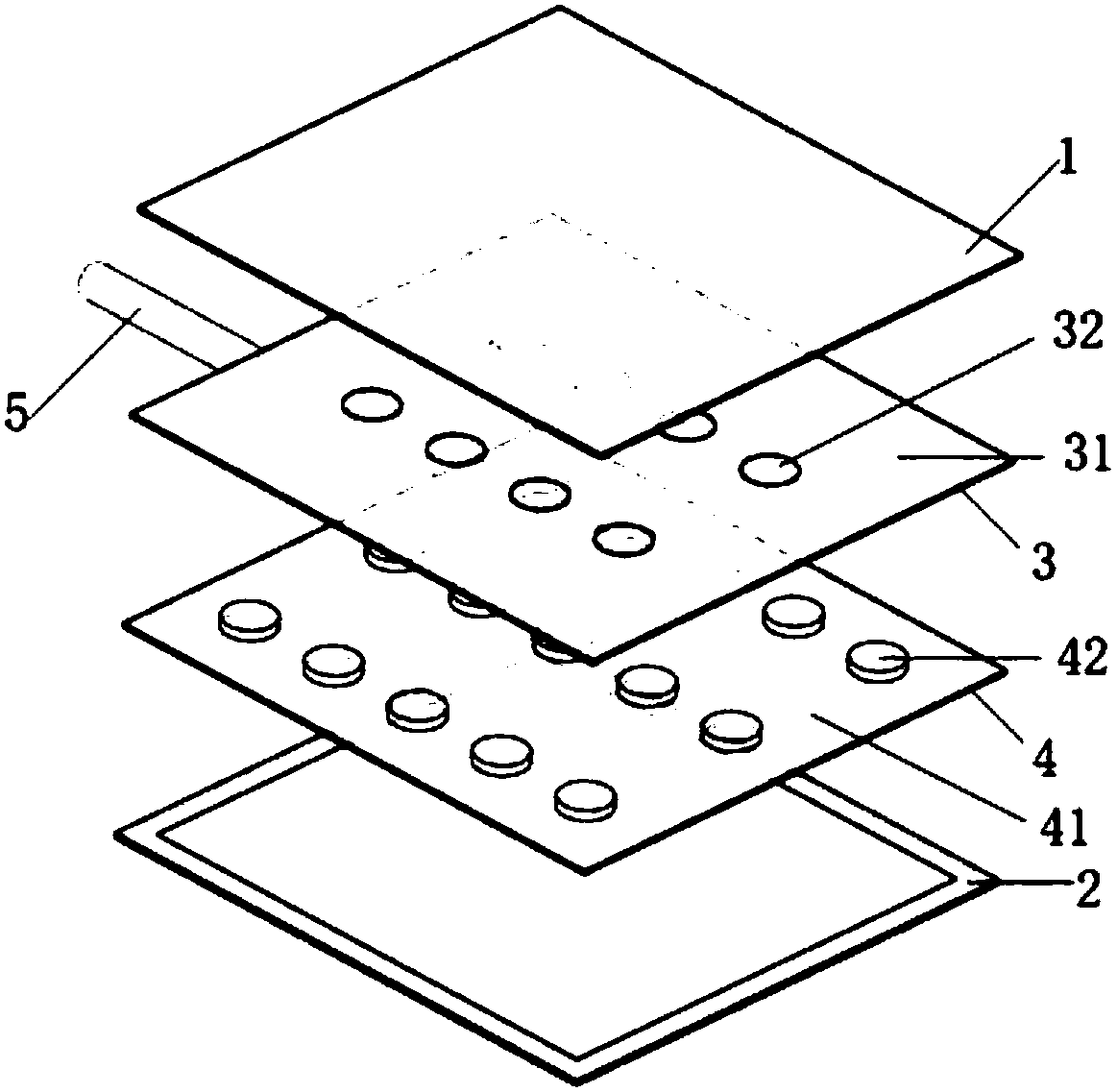

[0026] Such as figure 1 , 2 Shown is a flat heat pipe with a liquid-absorbing core support column integrated structure based on carbon nanotube arrays, including an upper metal cover 1 and a lower metal cover 2, and the upper metal cover 1 and the lower metal cover 2 pass through the edge Sealing forms a closed cavity, and the inside of the closed cavity after vacuuming is filled with working liquid, and the working medium used in this embodiment is water. On the inside of the upper metal cover 1 and the upper metal cover 2, an integrated structure of the liquid-absorbing core support column is respectively formed, forming an integrated structure 3 of the upper metal cover liquid-absorbent core support column and an integrated structure 4 of the lower metal cover liquid-absorbent core support column.

[0027] The upper metal cover plate liquid-absorbing core support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com