Fabric with enhanced flame retardant performance and preparation method thereof

A preparation process and fabric technology, applied in flame-retardant fibers, fabric surface trimming, textile material processing, etc., can solve the problems of strong damage to the fabric, poor flame-retardant effect and flame-retardant durability, and high price of flame-retardant fiber preparation technology. , to achieve the effect of improving quality and good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

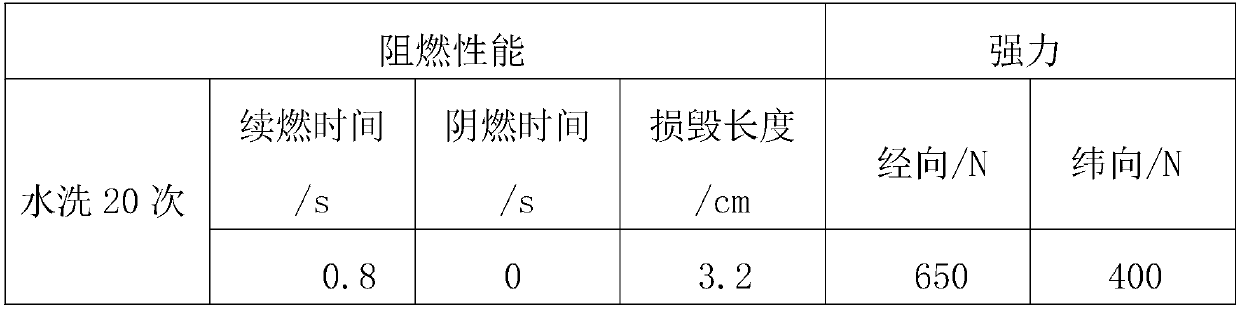

Examples

Embodiment Construction

[0043] Below in conjunction with embodiment the present invention is described in further detail.

[0044] A preparation process for flame-retardant reinforced fabrics, comprising the following steps: said blended yarn comprises the following steps:

[0045] 1) Preparation of blended yarn

[0046] Contain 20 weight of high-strength vinylon fiber, the balance is 40S blended yarn of cotton fiber, high-strength vinylon fiber is treated with softener before blending, and the preparation steps of blended yarn are as follows:

[0047] ① Preparation of mixed raw strips

[0048] a, according to the total weight 100kg of the yarn to be spun and the content of high-strength vinylon 20%, the fiber weight of the actual high-strength vinylon required for calculation is 20kg, which is divided into 2 parts on average;

[0049] B, according to the total weight of 100kg of yarn to be spun and the content of cotton fiber 80%, the weight of the actual cotton fiber needed for calculation is 80k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com