Sound-absorption coating composition

A technology of sound-absorbing paint and composition, applied in the field of paint, can solve the problems of not being able to adapt to the sound-absorbing paint, the cotton-like surface is not very beautiful, and the weather resistance of the paint is poor, and achieves the effects of reducing quality, preventing peeling and cracking, and improving weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

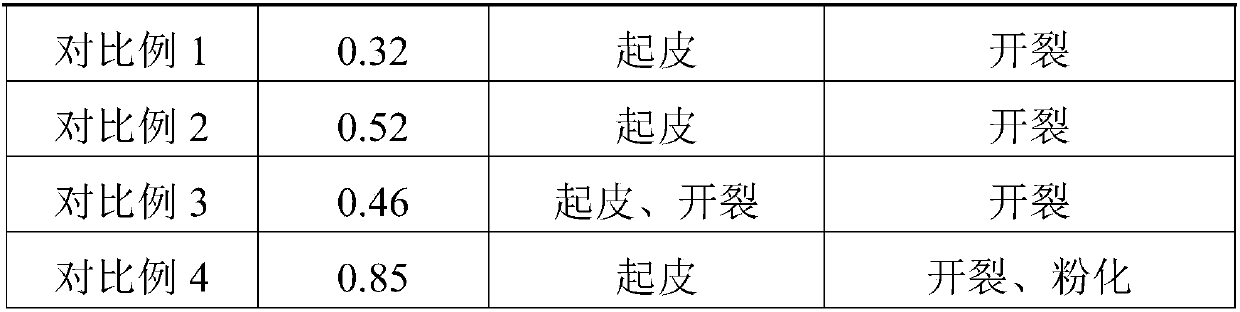

Examples

Embodiment 1

[0033] A preparation method of sound-absorbing coating composition:

[0034] (1) Mix 3000g of polyvinylidene fluoride emulsion and 300g of 4,4-oxobisbenzenesulfonyl hydrazide evenly and spin to obtain polymer fibers. The spinning process is: power supply voltage 60KV, spinning environment conditions are temperature 35°C, relative humidity 90%; the needle spacing of the multi-needle spinneret unit is 30cm, and the number of needleheads in the spinneret unit is 90;

[0035] (2) Place the polymer fiber obtained in step (1), 16.5g of ethylene glycol and 165g of sodium chloride in 100g of polyarylate emulsion, react for 30min under the condition of 90°C, and then react in 1mol / L acetic acid Soak in water for 20 minutes, replace the soaking solution every 30 minutes until no more sodium ions are precipitated, and then bake at 180°C for 20 minutes to obtain composite fibers;

[0036](3) Weigh and mix the water-based polyurethane emulsion, titanium dioxide and composite fiber at a ma...

Embodiment 2

[0039] A preparation method of sound-absorbing coating composition:

[0040] (1) Mix 3000g of polyethylene terephthalate emulsion and 270g of azodicarbonamide evenly and spin to obtain polymer fibers. The spinning process is: power supply voltage 60KV, and spinning environmental conditions are 35°C , the relative humidity is 90%; the distance between the needles of the multi-needle spinning unit is 30cm, and the number of needles in the spinning unit is 90;

[0041] (2) Place the polymer fiber obtained in step (1), 9.9g 1,3-butanediol and 163.5g sodium sulfate in 65.4g polyvinyl acetate emulsion, react at 85°C for 20min, and then react in 1mol Soak in / L formic acid for 20 minutes, replace the soaking solution every 30 minutes, until no more sodium ions are precipitated, and then bake at 160°C for 20 minutes to obtain composite fibers;

[0042] (3) Weigh and mix the water-based polyurethane emulsion, titanium dioxide and composite fiber at a mass ratio of 1:0.06:0.15, add 0.3...

Embodiment 3

[0045] A preparation method of sound-absorbing coating composition:

[0046] (1) Mix 3000g of polyarylate emulsion with 360g of N,N'-dinitrosopentamethylenetetramine and spin to obtain polymer fibers. The spinning process is: power supply voltage 60KV, spinning environment The conditions are a temperature of 35°C and a relative humidity of 90%; the needle spacing of the multi-needle spinneret unit is 30cm, and the number of needleheads of the spinneret unit is 90;

[0047] (2) Place the polymer fiber obtained in step (1), 30.24g 1,10-decanediol and 302.4g sodium nitrate in 134.4g nylon 6 emulsion, react at 95°C for 15-40min, and then Soak in 1mol / L boric acid for 20 minutes, replace the soaking solution every 30 minutes until no more sodium ions are precipitated, then bake at 190°C for 25 minutes to obtain composite fibers;

[0048] (3) Weigh and mix the water-based polyurethane emulsion, titanium dioxide and composite fiber at a mass ratio of 1:0.09:0.33, add 0.3% of the tot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com