Sewage treatment equipment

A technology of sewage treatment equipment and cylinders, which is applied in water/sewage multi-stage treatment, flotation water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of low oil removal rate, poor suspended particle effect, The problem of high surface tension of oil and water, etc., can improve the reaction efficiency, good oil drainage effect, and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

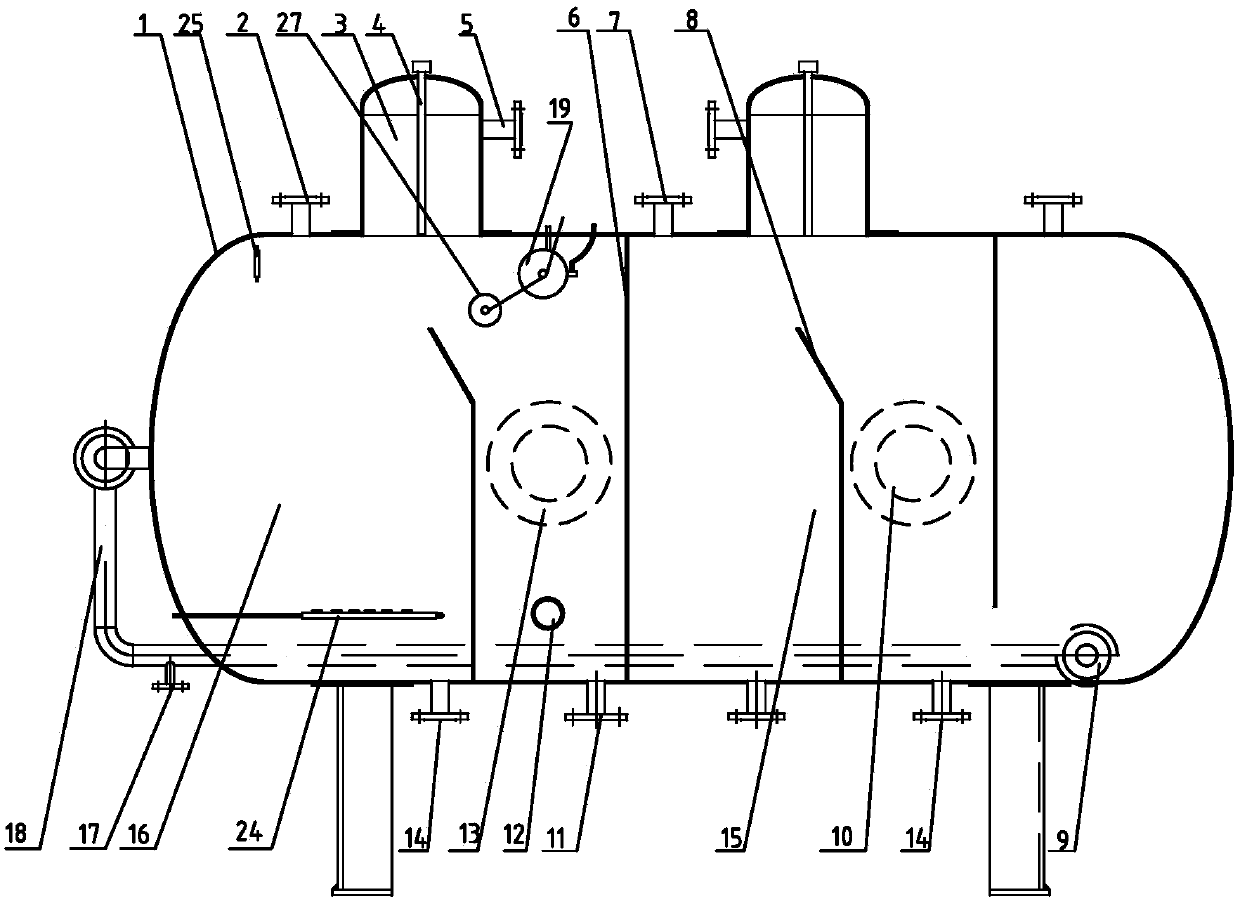

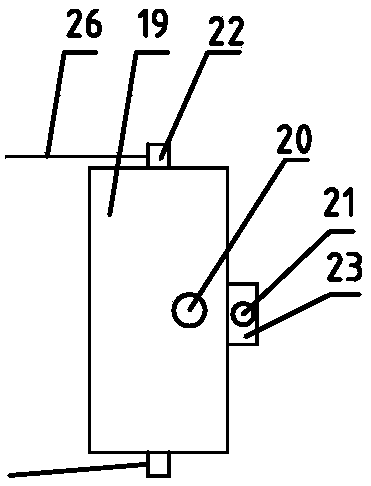

[0014] The present invention as Figure 1-2 As shown, it includes a cylinder 1, the cylinder includes a primary air flotation chamber 16 and a secondary air flotation chamber 15 separated by a partition 6, and the primary air flotation chamber is provided with a primary air flotation electrode 13 and a flow guide plate, the secondary air flotation chamber is provided with a secondary air flotation electrode 10 and a deflector 8, and the deflector is convenient to form a swirling flow and strengthen the degreasing effect; An exhaust port 2, an oil collection chamber 3, an oil discharge port 5, a sewage discharge port 14 and a water inlet (i.e., water inlet 11 and water inlet 2 9) are respectively provided. In the secondary air flotation chamber, the water inlet pipe is provided with a dosing port 17, and the secondary air flotation chamber is provided with a water outlet 7;

[0015] It also includes an air blowing mechanism, a buoy 27 and a lifting mechanism. The air blowing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com