Microwave plasma industrial organic waste gas treatment system

A microwave plasma, microwave plasma technology, applied in gas treatment, separation method, separation of dispersed particles, etc., to achieve the effect of simple structure and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the technical solution of the present invention is further described as follows:

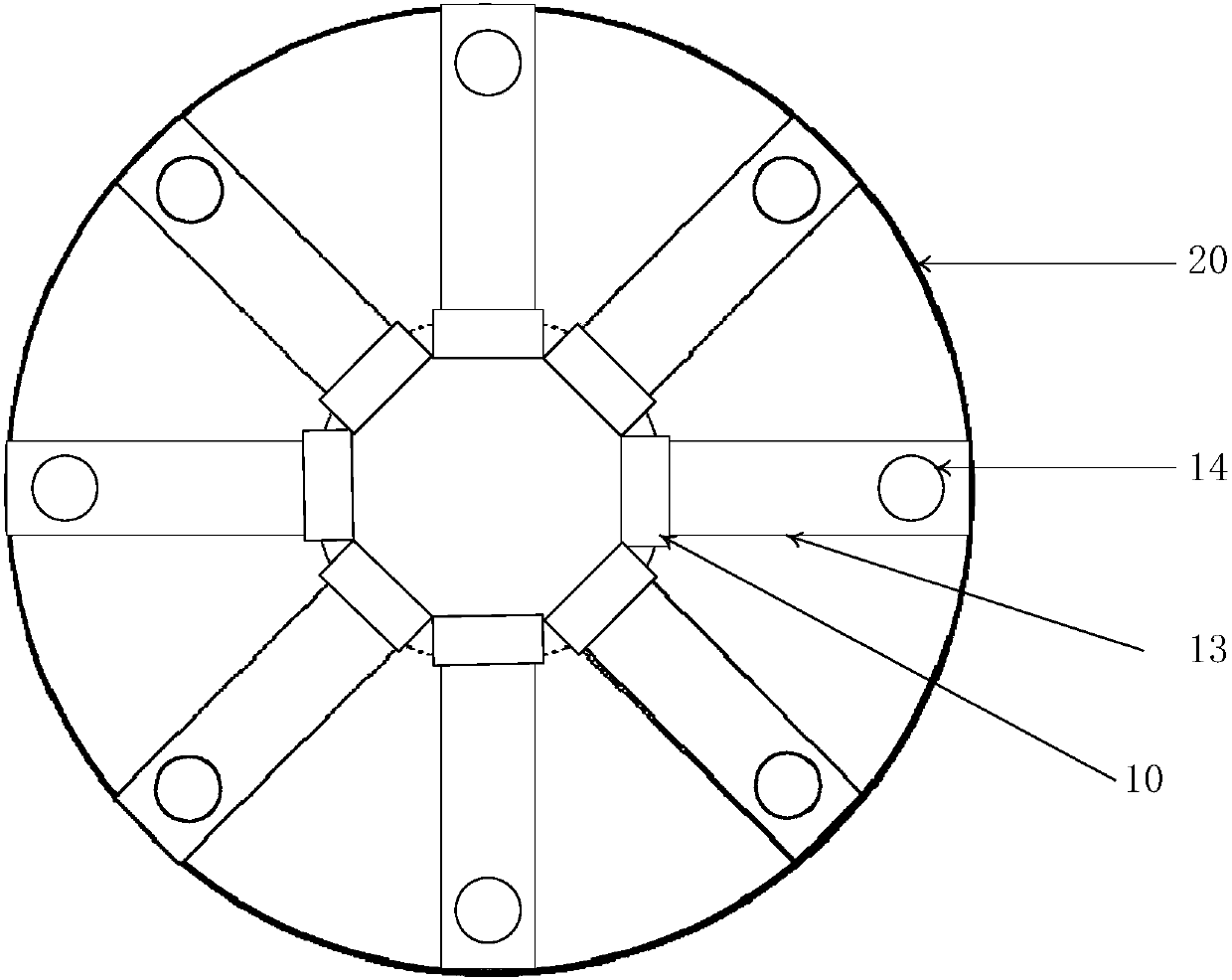

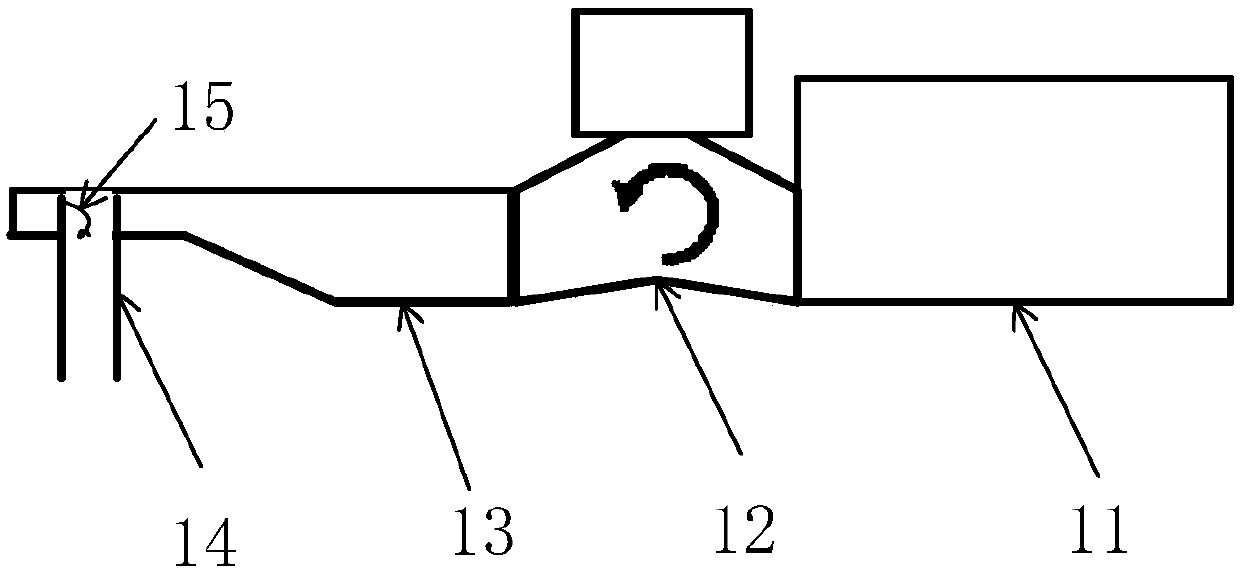

[0015] A microwave plasma industrial organic waste gas treatment system proposed by the present invention, the overall structure is as follows figure 1 As shown, the system is fixedly installed in an industrial exhaust gas pipeline (generally cylindrical), and includes a housing 20 that matches the size of the industrial exhaust gas pipeline and a plurality of (such as 3 to 12) uniformly distributed circumferentially fixed in the housing. different) same microwave plasma torch generating device 10; each microwave plasma torch generating device 10 all comprises a microwave generator 11 connected in sequence (the control system of the microwave generator is located in the control room outside the industrial waste gas pipeline, and the user will The treated industrial organic waste gas flow is adjusted by the control syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com