Aluminum alloy refining agent containing rare earth compounds and preparation method for same

A rare earth compound and refining agent technology, which is applied in the field of aluminum alloy processing, can solve the problem of high content of non-metallic inclusions, achieve good impurity removal effect, reduce metal burning loss, and uniform microstructure compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

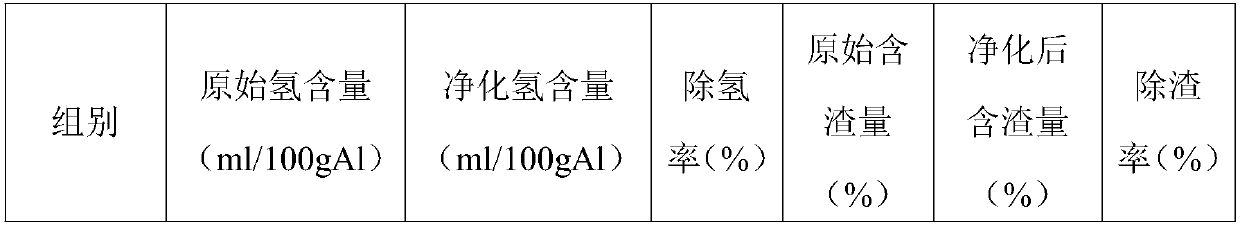

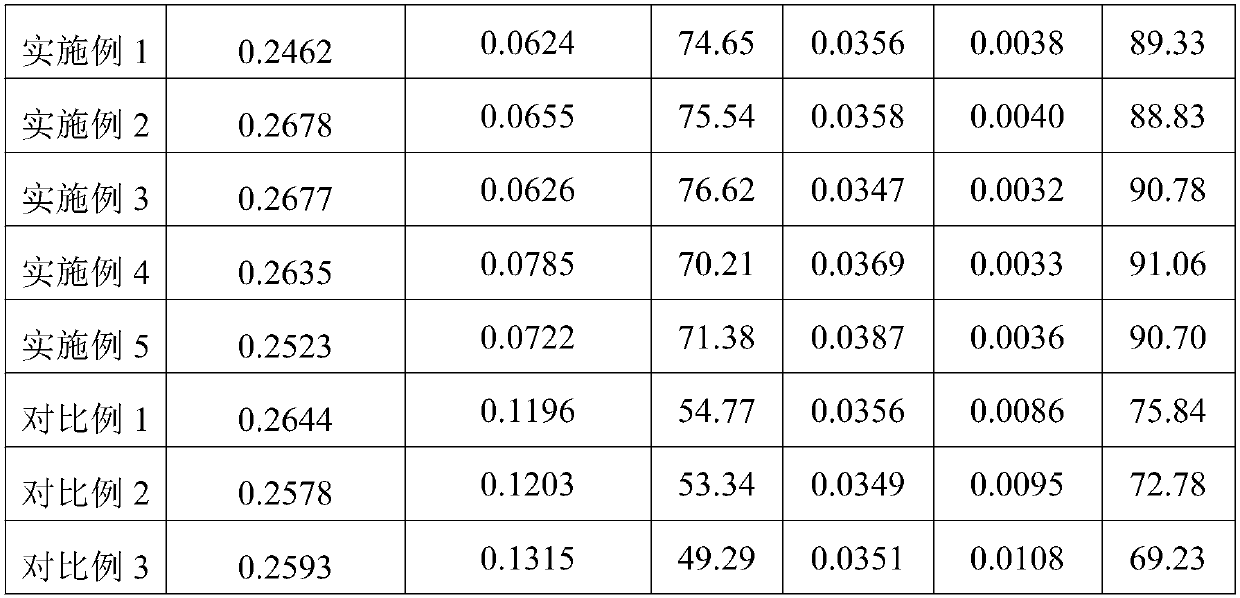

Examples

preparation example Construction

[0024] The preparation method of the aluminum alloy refining agent containing the rare earth compound comprising the above raw materials and components comprises the following steps:

[0025] S1: La 2 o 3 Dissolve in hydrochloric acid and dilute to 120-130g / L, heat the solution to 72-75°C, add 48% hydrofluoric acid, stir to obtain a precipitate, then wash, filter, and dry the precipitate until the water content is ≤2% , crushed to a particle size of ≤2mm, and dehydrated under the condition of a vacuum of 0.5-0.8MPa to obtain F 3 La powder;

[0026] S2: put Nd 2 o 3 Dissolve in hydrochloric acid and dilute to 120-130g / L, heat the solution to 72-75°C, add 48% hydrofluoric acid, stir to obtain a precipitate, then wash, filter, and dry the precipitate until the water content is ≤2% , Grinding to particle size ≤ 2mm, and dehydrating under the condition of vacuum degree of 0.5-0.8MPa to obtain FNd powder;

[0027] S3: KCl, BaSO 4 、KNO 3 , A1F 3 , CaS, Na 3 A1F 6 、Na 2 Si...

Embodiment 1

[0030] A refining agent for aluminum alloy containing rare earth compounds, in parts by weight, comprising the following components: 50 parts of KCl, BaSO 4 15 copies, KNO 3 30 copies, A1F 3 11 parts, 4 parts of CaS, Na 3 A1F6 10 parts, Na 2 SiF 6 3 parts, FNd 0.6 parts, F 3 0.5 parts of La, 0.6 parts of graphite;

[0031] The preparation method of the aluminum alloy refining agent containing the rare earth compound comprising the above raw materials and components comprises the following steps:

[0032] S1: La 2 o 3 Dissolve in hydrochloric acid and dilute to 130g / L, heat the solution to 75°C, add 48% hydrofluoric acid, stir to obtain a precipitate, then wash, filter, dry the precipitate to a water content of ≤2%, and crush to particle size ≤2mm, dehydration under the condition of vacuum degree of 0.6MPa to get F 3 La powder;

[0033] S2: put Nd 2 o 3 Dissolve in hydrochloric acid and dilute to 130g / L, heat the solution to 75°C, add 48% hydrofluoric acid, sti...

Embodiment 2

[0037] A refining agent for aluminum alloy containing rare earth compounds, in parts by weight, comprising the following components: 60 parts of KCl, BaSO 4 10 copies, KNO 3 40 copies, A1F 3 7 parts, CaS 9 parts, Na 3 A1F 6 8 parts, Na 2 SiF 6 2 parts, FNd 0.3 parts, F 3 1.1 parts of La, 0.3 parts of graphite;

[0038] The preparation method of the aluminum alloy refining agent containing the rare earth compound comprising the above raw materials and components comprises the following steps:

[0039] S1: La 2 o 3 Dissolve in hydrochloric acid and dilute to 125g / L, heat the solution to 74°C, add 48% hydrofluoric acid, stir to obtain a precipitate, then wash, filter, dry the precipitate to a water content of ≤2%, and crush to particle size ≤2mm, dehydration under the condition of vacuum degree of 0.5MPa to get F 3 La powder;

[0040] S2: put Nd 2 o 3 Dissolve in hydrochloric acid and dilute to 125g / L, heat the solution to 74°C, add 48% hydrofluoric acid, stir t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com