High-energy density type lithium cobaltate cathode material and preparation method thereof

A technology of high energy density and positive electrode material, applied in the field of high energy density lithium cobalt oxide positive electrode material and its preparation, to achieve the effects of stable structure, uniform distribution and improved lithium ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

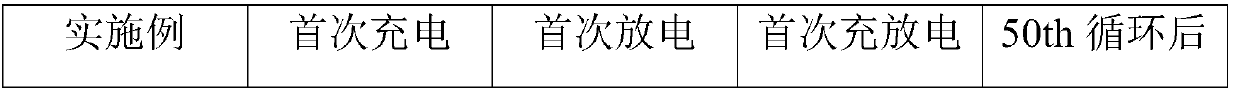

Examples

preparation example Construction

[0021] The preparation method of the high energy density type lithium cobaltate cathode material provided by the invention comprises the following steps:

[0022] (1) Doping the Ni element into the cobalt source, then mixing it with the lithium source and the compound of the doping element M in proportion, and obtaining primary cobalt oxide particles after ball milling, sintering, crushing, and sieving; wherein the doped The heteroelement M is at least one of Mn, Mg, Al, Ti, and Zr.

[0023] In this step, the cobalt source is firstly prepared, and then the cobalt source is doped with nickel element. The doping process can be either dry or wet, and will not be described here. Then mix the cobalt source containing the doping element Ni with the lithium source and the compound of the doping element M according to a certain metering ratio, and obtain primary lithium cobaltate particles after ball milling, sintering, crushing, and sieving. Here, the primary lithium cobaltate parti...

Embodiment 1

[0035] Weighing and mixing tricobalt tetroxide pre-doped with Ni element, lithium carbonate and manganese dioxide according to a certain metering ratio. Wherein the Ni content is 0.5wt%, the Mn content is 0.5wt%, and the ratio of lithium to metal is 1.020. The weighed mixture was placed in a ball mill jar, and ball milled for 60 min at a speed of 300 rad / s. Then put it into a roller furnace, and sinter at 1080°C for 10 hours, and continuously feed air as an oxygen source during the sintering process. The sintered material is mechanically crushed and crushed, and then passed through a 325-mesh screen to obtain primary lithium cobaltate particles.

[0036] The primary lithium cobaltate particles, lithium carbonate, magnesium hydroxide, ammonium fluoride, ammonium dihydrogen phosphate, and vanadium pentoxide are weighed and mixed according to a certain metering ratio. Among them, Li:F:PO 4 3- : V=1:1:1:1, Mg content is 500ppm, LiVPO 4 F: LiCoO 2 The mass ratio is 1:99. Dis...

Embodiment 2

[0040] Weighing and mixing tricobalt tetroxide pre-doped with Ni element, lithium carbonate, manganese dioxide and magnesium hydroxide according to a certain metering ratio. Wherein the Ni content is 0.5wt%, the Mn content is 0.5wt%, the Mg content is 0.12wt%, and the ratio of lithium to metal is 1.020. The weighed mixture was placed in a ball mill jar, and ball milled for 60 min at a speed of 300 rad / s. Then put it into a roller furnace, and sinter at 1080°C for 10 hours, and continuously feed air as an oxygen source during the sintering process. The sintered material is mechanically crushed and crushed, and then passed through a 325-mesh screen to obtain primary lithium cobaltate particles.

[0041] The primary lithium cobaltate particles, lithium carbonate, magnesium hydroxide, ammonium fluoride, ammonium dihydrogen phosphate, and vanadium pentoxide are weighed and mixed according to a certain metering ratio. Among them, Li:F:PO 4 3- : V=1:1:1:1, Mg content is 500ppm, L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com