Polystyrene plastic coating

A technology for polystyrene plastics and coatings, applied in the field of coatings, can solve problems such as damage to the digestive system, and achieve the effect of excellent waterproofness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

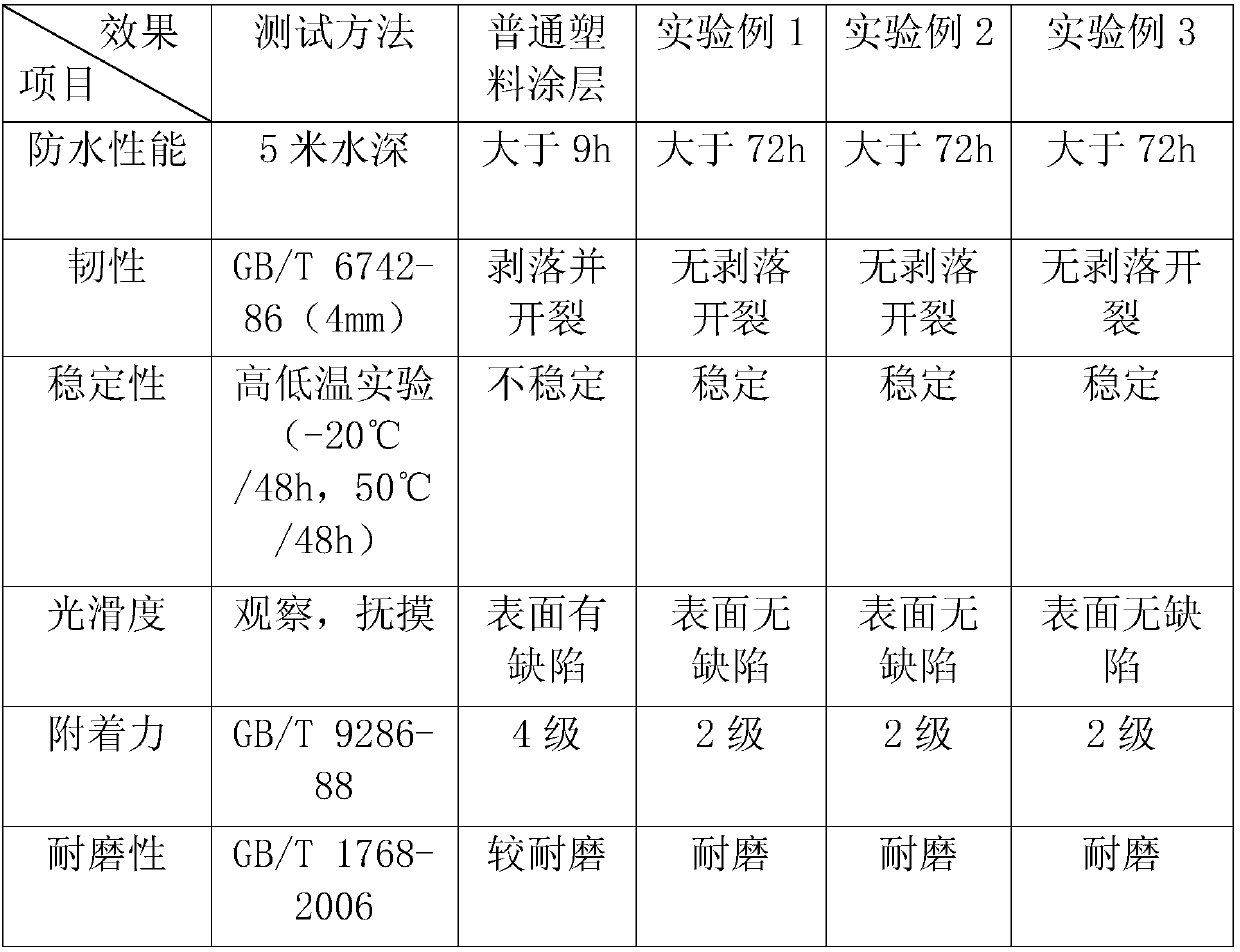

Examples

preparation example Construction

[0014] The preparation method of described coating comprises the following steps:

[0015] (a) Crush polystyrene (PS) plastic to a volume of 0.1-0.25cm 3 Wash and dry afterwards;

[0016] (b) add the polystyrene (PS) plastic that is filled with butyl acetate solution, cyclohexanone solution, toluene solution and carry out heating and stirring after (a) processing;

[0017] (c) After filtering the material of (b), add nano-active calcium carbonate, polyoxypropylene glyceryl ether, antioxidant DNP, epoxy resin adhesive, water, plasticizer (DEHP), OP-10, dodecyl Sodium benzenesulfonate can be cooled after heating and stirring.

[0018] In the step (b), the stirring temperature is 50-65° C., the stirring time is 60-80 min, and the stirring speed is 600-800 r / min.

[0019] In the step (c), the stirring temperature is 30-50° C., the stirring time is 30-60 min, and the stirring speed is 800-1000 r / min.

Embodiment 1

[0021] A polystyrene plastic paint, comprising polystyrene (PS) plastics is 18 parts, butyl acetate solution is 15 parts, cyclohexanone solution is 18 parts, toluene solution is 12 parts, nano active calcium carbonate is 8 parts, Polyoxypropylene glyceryl ether is 3 parts, antioxidant DNP is 2 parts, epoxy resin adhesive is 3 parts, water is 15 parts, plasticizer (DEHP) is 3 parts, OP-10 is 7 parts, dodecane Sodium phenyl sulfonate is 2 parts; Preparation comprises the following steps:

[0022] (a) Crush polystyrene (PS) plastic to a volume of 0.1-0.25cm 3 Wash and dry afterwards;

[0023] (b) Add the polystyrene (PS) plastics after (a) into a stirring vessel filled with butyl acetate solution, cyclohexanone solution and toluene solution and heat and stir. The stirring temperature is 50°C, and the stirring time is 60min, the stirring speed is 600r / min;

[0024] (c) After filtering the material of (b), add nano activated calcium carbonate, polyoxypropylene glyceryl ether, an...

Embodiment 2

[0026] A polystyrene plastic paint, comprising polystyrene (PS) plastics is 20 parts, butyl acetate solution is 16 parts, cyclohexanone solution is 20 parts, toluene solution is 14 parts, nano active calcium carbonate is 9 parts, 3 parts of polyoxypropylene glyceryl ether, 3 parts of antioxidant DNP, 3 parts of epoxy resin adhesive, 18 parts of water, 4 parts of plasticizer (DEHP), 8 parts of OP-10, dodecane Sodium phenyl sulfonate is 2 parts; Preparation comprises the following steps:

[0027] (a) Crush polystyrene (PS) plastic to a volume of 0.1-0.25cm 3 Wash and dry afterwards;

[0028] (b) Add the polystyrene (PS) plastics after (a) into a stirring vessel filled with butyl acetate solution, cyclohexanone solution and toluene solution and heat and stir. The stirring temperature is 60° C., and the stirring time is 70min, stirring speed is 700r / min;

[0029] (c) After filtering the material of (b), add nano activated calcium carbonate, polyoxypropylene glyceryl ether, anti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com