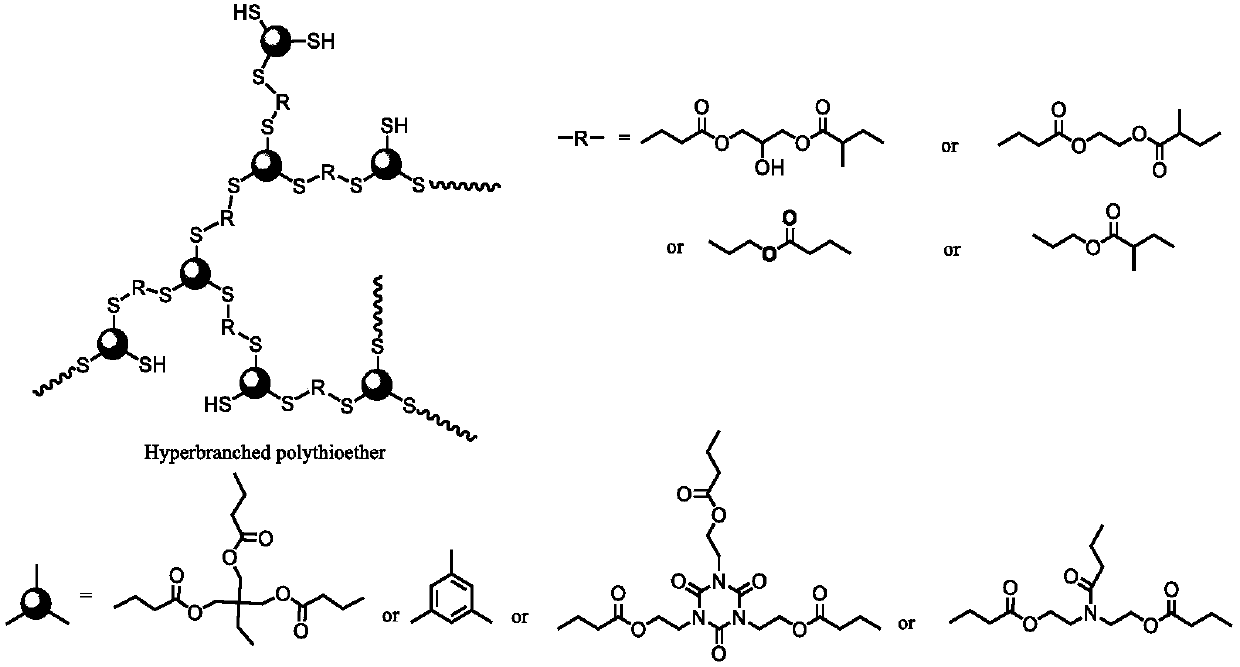

Hyperbranched polythioether preparation method

A technology of polysulfide and thiol, which is applied in the field of preparation of hyperbranched polysulfide, can solve the problems of few types of monomers, prone to cross-linking, poor selectivity, etc. Highly controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0023] 9.965g (25mmol) 2-ethylglycerol trimercaptopropionate, 75mL tetrahydrofuran and 5.355g (25mmol) 3-(acryloyloxy)-methacrylic acid-2-hydroxypropyl ester and 0.1265g (1.25 mmol) triethylamine was added to the reactor at one time, and N at 40°C 2 Protect the reaction for 48 hours; after the reaction, the reaction solution was concentrated by rotary evaporation, redissolved in chloroform and precipitated in anhydrous ether, and the dissolution-precipitation operation was repeated 3 times, and the precipitate was vacuum-dried to obtain a colorless viscous liquid product hyperbranched polysulfide (12.68 g, 82.8% yield).

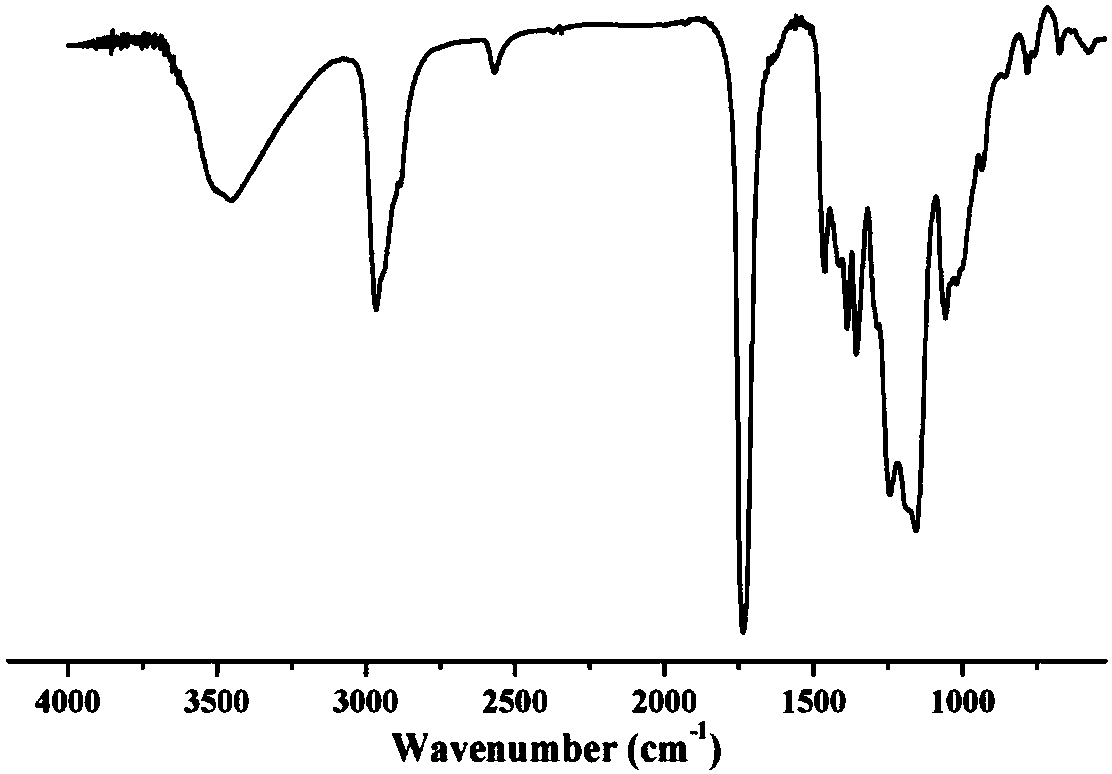

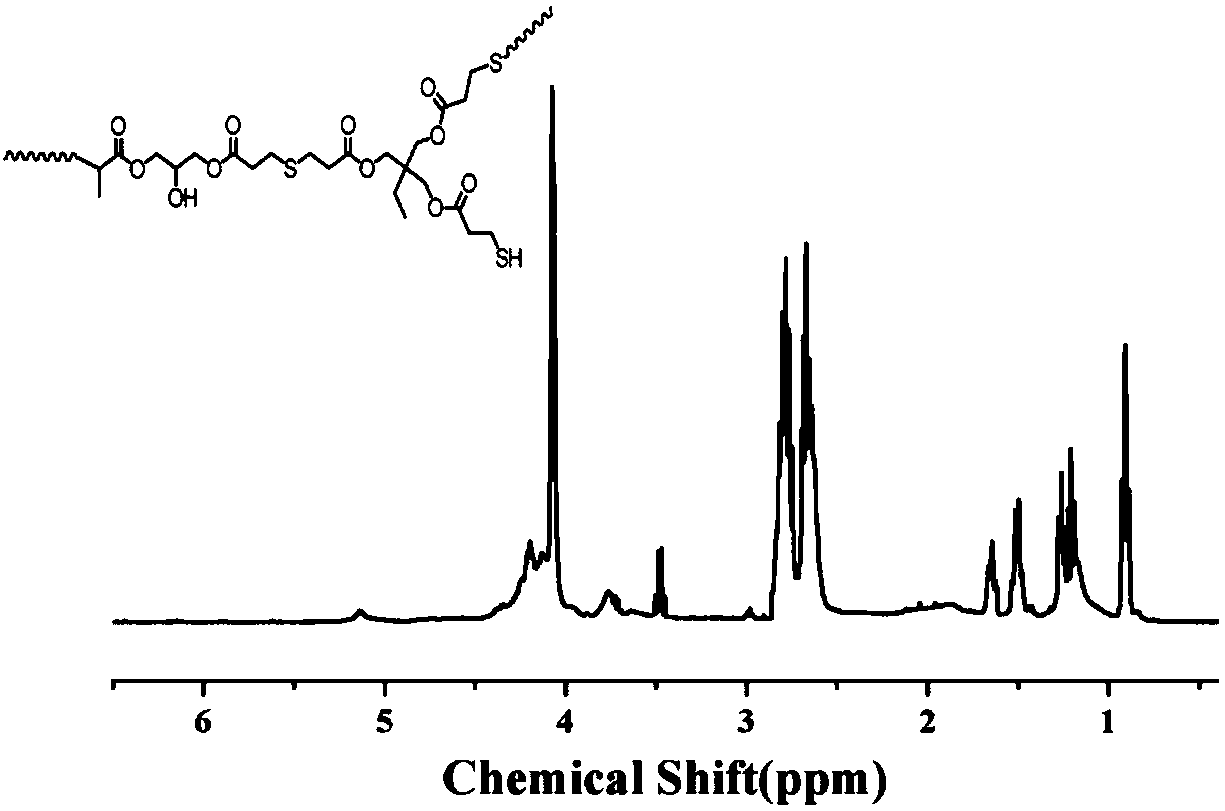

[0024] figure 2 It is the infrared absorption spectrogram of the hyperbranched polysulfide prepared in Example 1, wherein the 3505cm-1 place is the stretching vibration absorption peak of OH, the 2540cm-1 place is the characteristic absorption peak of thiol, and the double bond characteristic at 1600cm-1 place The peaks disappeared completely, proving the ...

Embodiment example 2

[0028] 9.965g (25mmol) 2-ethylglycerol trimercapto propionate, 75mL dioxane and 5.355g (25mmol) 3-(acryloyloxy)-methacrylic acid-2-hydroxypropyl ester and 0.1265 g (1.25mmol) triethylamine was added to the reactor at one time, and N at 40°C 2 Protect the reaction for 48 hours; after the reaction, the reaction solution was concentrated by rotary evaporation, redissolved in chloroform and precipitated in anhydrous ether, and the dissolution-precipitation operation was repeated 3 times, and the precipitate was vacuum-dried to obtain a colorless viscous liquid product hyperbranched polysulfide (12.44 g, 81.2% yield).

Embodiment example 3

[0030] 10.961g (27.5mmol) 2-ethylglycerol trimercaptopropionate, 75mL tetrahydrofuran and 5.355g (25mmol) 3-(acryloyloxy)-methacrylic acid-2-hydroxypropyl ester and 0.1265g ( 1.25mmol) triethylamine is added in the reactor at one time, and under 40 ℃, N 2 Protect the reaction for 24 hours; after the reaction, the reaction solution was concentrated by rotary evaporation, redissolved in chloroform and precipitated in anhydrous ether, and the dissolution-precipitation operation was repeated 3 times, and the precipitate was vacuum-dried to obtain a colorless viscous liquid product hyperbranched polysulfide (11.13 g, 68.2% yield).

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

| Branching factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com