Imitated active paint printing adhesive, and preparation method and application method thereof

A paint printing and adhesive technology, applied in dyeing, textile and papermaking, etc., can solve the problems of waste of raw materials, low solid content, poor bonding effect, etc., to enhance application performance, improve performance indicators, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

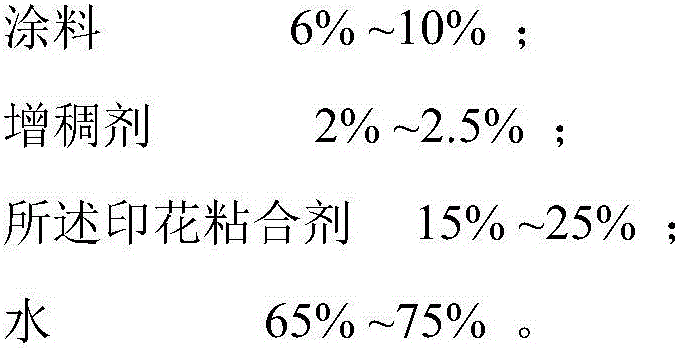

Examples

Embodiment 1

[0047] Weigh 131 g of butyl acrylate, 54 g of isooctyl acrylate, 40 g of methyl methacrylate, 16 g of styrene, 8 g of acrylic acid, 10.3 g of N-methylol acrylamide, and 10 g of castor oil polyoxyethylene ether phosphate triethanolamine salt. 1.8 g of double bond group-containing bisalkylsulfosuccinate salt, 2.4 g of fatty alcohol polyoxyethylene ether, 0.52 g of sodium persulfate, and 80 g of deionized water are added to the first reaction vessel to obtain a raw material mixture;

[0048] Stir the raw material mixture continuously for 20 minutes at a speed of 1800 rpm to 2200 rpm at room temperature;

[0049] Using a high-pressure homogenizer to emulsify the raw material mixture for 30 minutes to prepare a milky white pre-emulsion without layering;

[0050] Weigh 40g of pre-emulsion into the second reaction vessel;

[0051] Adding 0.9 g of bis-alkyl sulfosuccinate containing double bond groups, 0.52 g of sodium persulfate and 145 g of deionized water into the second reaction vessel;

...

Embodiment 2

[0058] Weigh 131g butyl acrylate, 54g isooctyl acrylate, 20g acrylonitrile, 36g styrene, 8g acrylic acid, 10.3g N-methylol acrylamide, 10g castor oil polyoxyethylene ether phosphate triethanolamine salt, containing double bond 1.8 g of dialkyl sulfosuccinate salt, 2.4 g of fatty alcohol polyoxyethylene ether, 0.52 g of sodium persulfate, and 80 g of deionized water were added to the first reaction vessel to obtain a raw material mixture;

[0059] Stir the raw material mixture continuously for 20 minutes at a speed of 1800 rpm to 2200 rpm at room temperature;

[0060] Using a high-pressure homogenizer to emulsify the raw material mixture for 30 minutes to prepare a milky white pre-emulsion without layering;

[0061] Weigh 40g of pre-emulsion into the second reaction vessel;

[0062] Adding 0.9 g of bis-alkyl sulfosuccinate containing double bond groups, 0.52 g of sodium persulfate and 145 g of deionized water into the second reaction vessel;

[0063] Start stirring, continue to stir the...

Embodiment 3

[0069] Weigh 130g butyl acrylate, 53g isooctyl acrylate, 20g acrylonitrile, 36g styrene, 8g acrylic acid, 5g hydroxyethyl acrylate, 5g diacetone acrylamide, 12g fatty alcohol polyoxyethylene ether phosphate triethanolamine salt, containing 1.8 g of double-bond bis-alkyl sulfosuccinate salt, 2.4 g of castor oil polyoxyethylene ether, 0.52 g of sodium persulfate, and 80 g of deionized water are added to the first reaction vessel to obtain a raw material mixture;

[0070] Stir the raw material mixture continuously for 20 minutes at a speed of 1800 rpm to 2200 rpm at room temperature;

[0071] Using a high-pressure homogenizer to emulsify the raw material mixture for 30 minutes to prepare a milky white pre-emulsion without layering;

[0072] Weigh 40g of pre-emulsion into the second reaction vessel;

[0073] Adding 0.9 g of bis-alkyl sulfosuccinate containing double bond groups, 0.52 g of sodium persulfate and 145 g of deionized water into the second reaction vessel;

[0074] Start stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com