Recovery method and recovery device for discharged cooling water

A recycling method and recycling device technology, which are applied in water shower coolers, cleaning heat transfer devices, chemical instruments and methods, etc., can solve the problems of pre-treatment membrane, RO membrane clogging, weak polymer anti-corrosion effect, etc. Phosphorus concentration, reduced treatment costs, and improved water recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

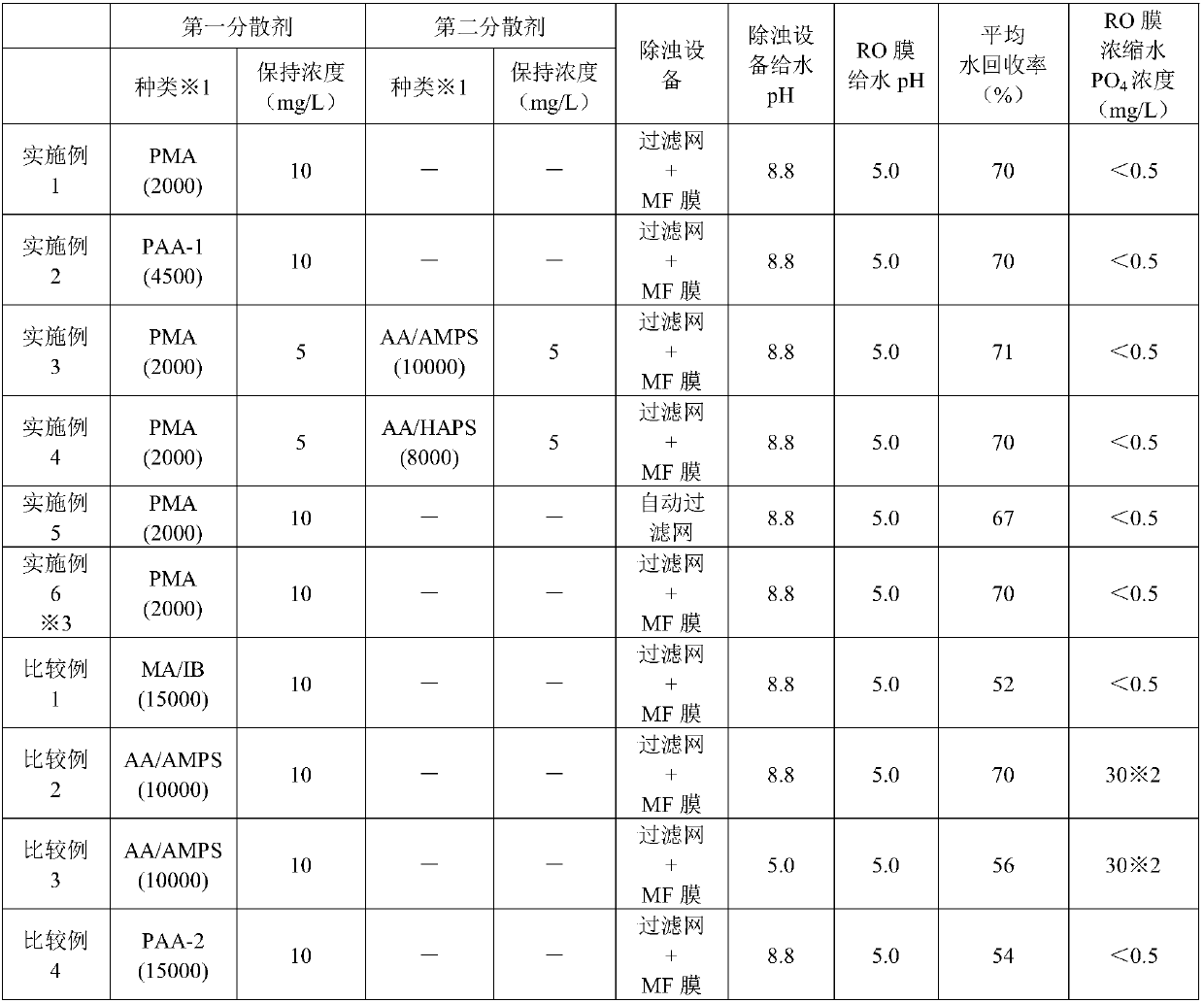

[0134] Using PMA with a weight-average molecular weight of 2000 as the cooling water of the dispersant, the turbidity removal equipment uses a filter screen and MF membrane device to treat the discharge water in the order of the filter screen, MF membrane device, and RO membrane device for water recovery.

[0135] The mesh aperture of the filter is 400 μm. As the MF membrane, "Pyuria GS" (hydrophilized PVDF, pore size: 0.02 µm, external pressure type) manufactured by Kuraray was used. As the RO membrane, "KROA-2032-SN (polyamide ultra-low pressure RO membrane)" manufactured by Kurita Kogyo Co., Ltd. was used. The cleaning frequency of the MF membrane device is 1 time / 30 minutes.

[0136] The discharge water is passed through the filter screen and the MF membrane device in sequence without adjusting the pH, and then sulfuric acid is added to the inlet side of the RO membrane device to adjust the pH to 5.0. Similarly, sodium bisulfite is added to the inlet side of the RO membr...

Embodiment 2

[0141] In place of PMA with a weight average molecular weight of 2000, 10 mg / L of PAA-1 (on a solid basis) with a weight average molecular weight of 4500 was added as a dispersant, and discharge water was recovered in the same manner as in Example 1. Table 1 shows the average water recovery rate and the phosphate ion concentration of RO membrane concentrated water.

Embodiment 3

[0143] Add the PMA 5mg / L (by solid basis) of molecular weight 2000 as the first dispersant, and the AA / AMPS 5mg / L (by solid basis) of molecular weight 10000 as the second dispersant, replace the PMA of weight average molecular weight 2000, except Other than that, the discharge water was recovered in the same manner as in Example 1. Table 1 shows the average water recovery rate and the phosphate ion concentration of RO membrane concentrated water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com