Lubricating oil mist exhaust system and exhaust cover of axle hub cavity

A technology of lubricating oil and exhaust cover, which is applied to shafts, bearings, rigid brackets of bearing components, bearing components, etc. It can solve problems such as polluted lubricating oil, dirty hub end faces, easy to block hub cavity pressure, etc., and achieve exhaust Unobstructed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

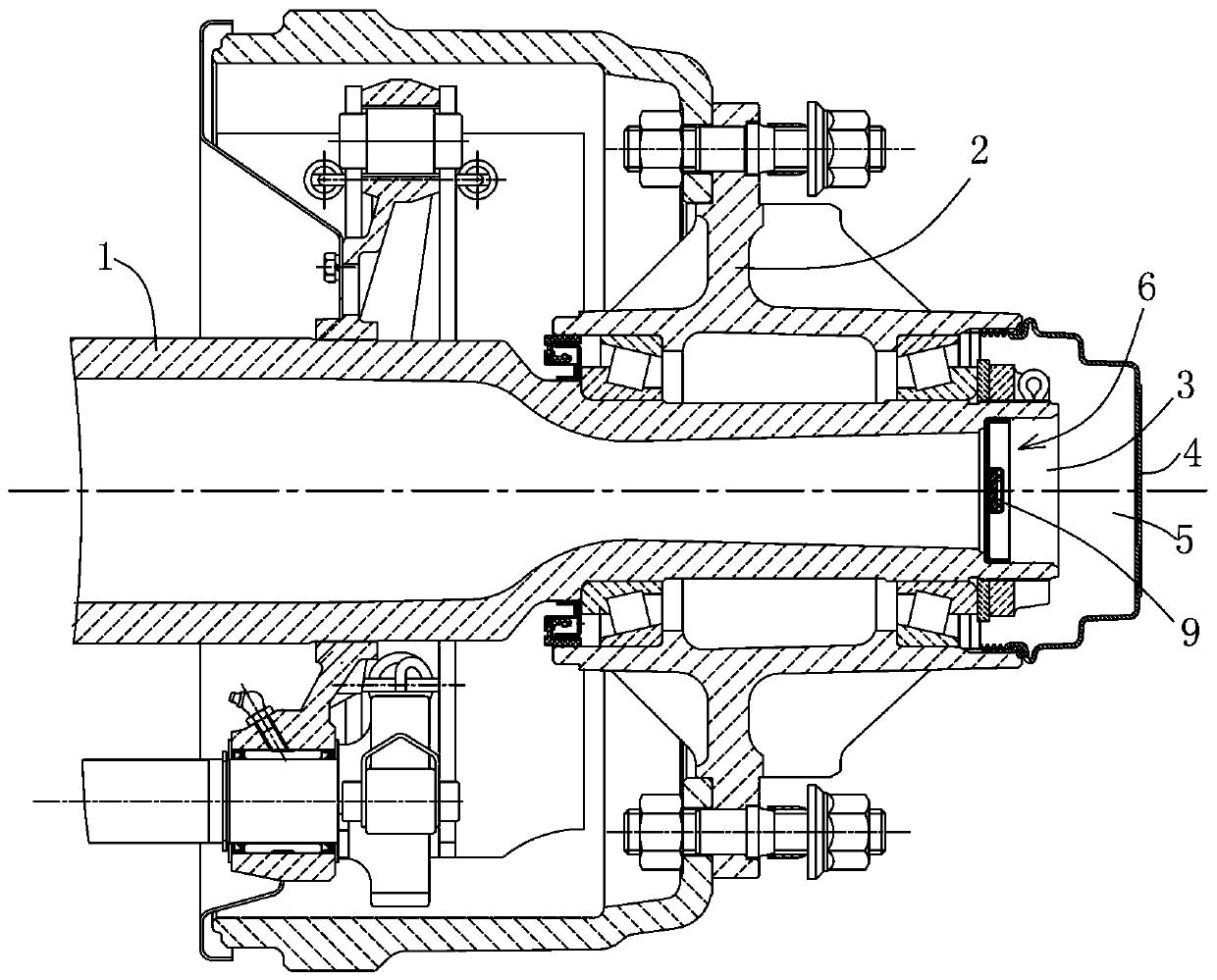

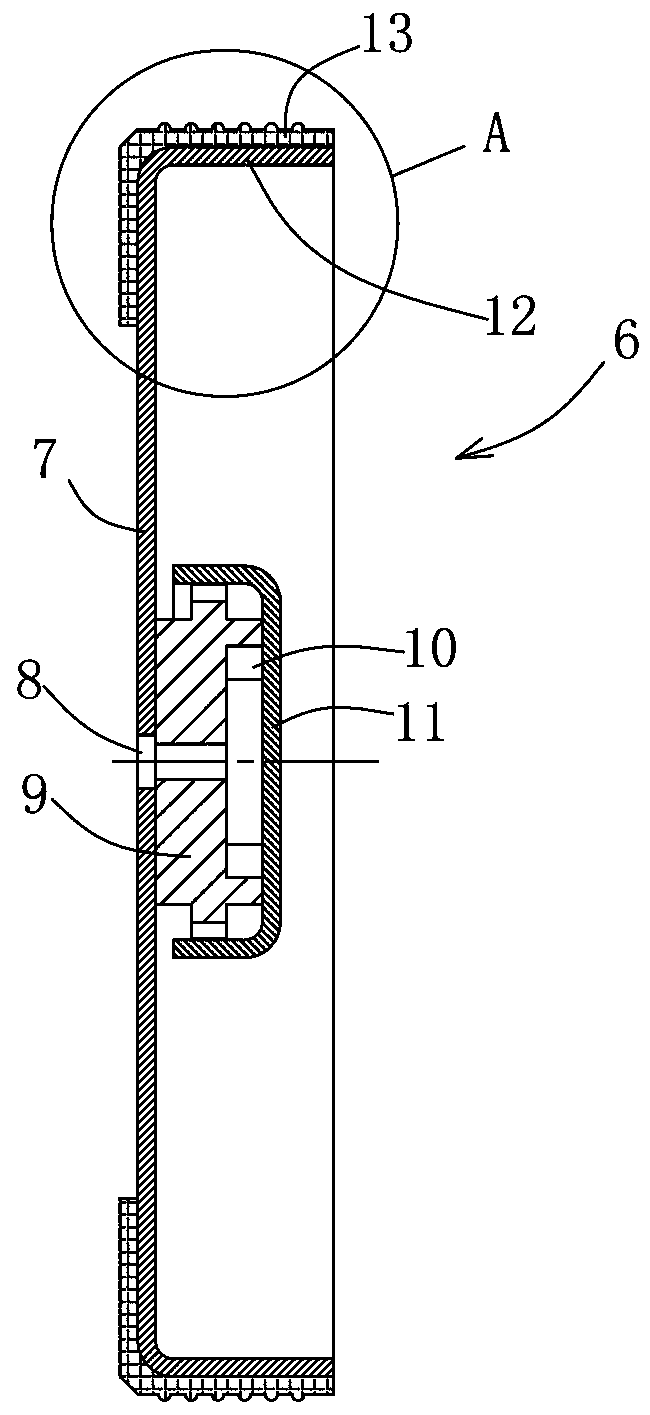

[0019] The lubricating oil mist discharge system of the axle hub cavity such as figure 1 As shown, it includes an axle 1 and a hub 2 installed at the end of the axle 1 , the end of the axle 1 has an end hole 3 , and the hub 2 is provided with a hub chamber 5 sealed by a hub end cover 4 . In the end hole 3 is covered with an exhaust cover 6, the exhaust cover 6 is figure 2 In the shown lubricating oil mist exhaust cap, the periphery of the exhaust cap 6 is closely matched with the inner wall of the end hole 3 , so that the exhaust cap 6 is firmly fixed in the end hole 3 .

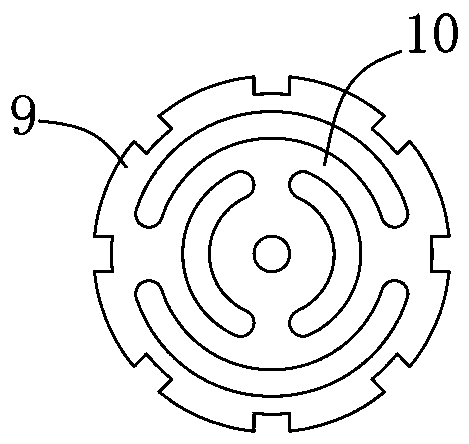

[0020] see figure 2 , The lubricating oil mist exhaust cover 6 includes a cover body 7, the cover body 7 can be formed by metal stamping or machining, and the cover body 7 is provided with exhaust holes 8 running through the end faces of the two ends of the cover body. An exhaust valve core 9 covering the exhaust hole 8 is arranged on one end surface of the cover body 7 . exist figure 1 In the shown lu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com