Coolant cleaning device for machine tool

A technology of working machinery and purification devices, which is applied to metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve problems such as regular cleaning, and achieve the effect of reducing maintenance work time and reducing maintenance work time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

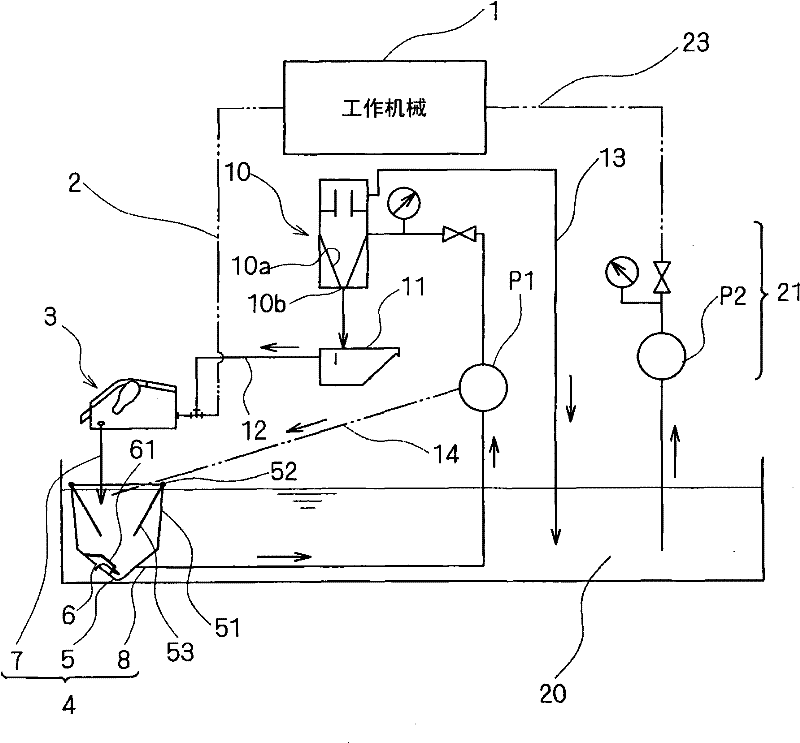

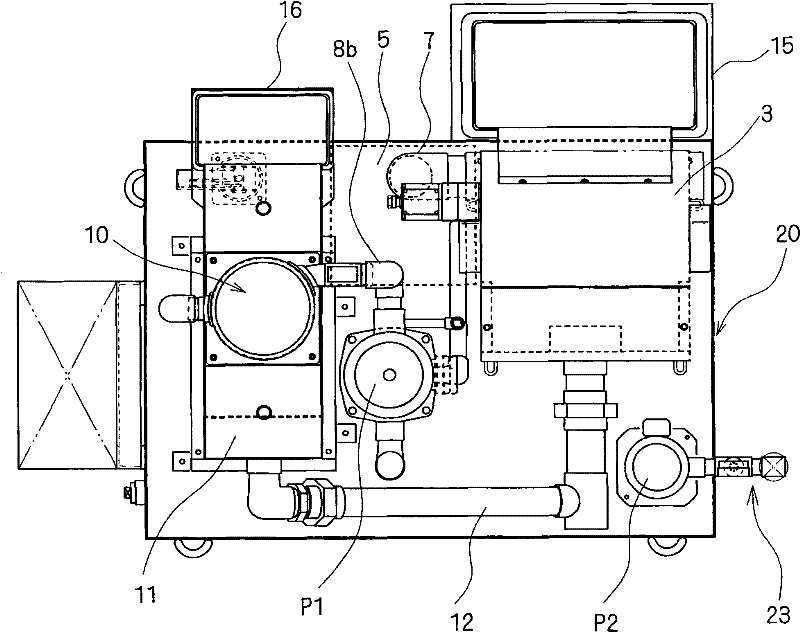

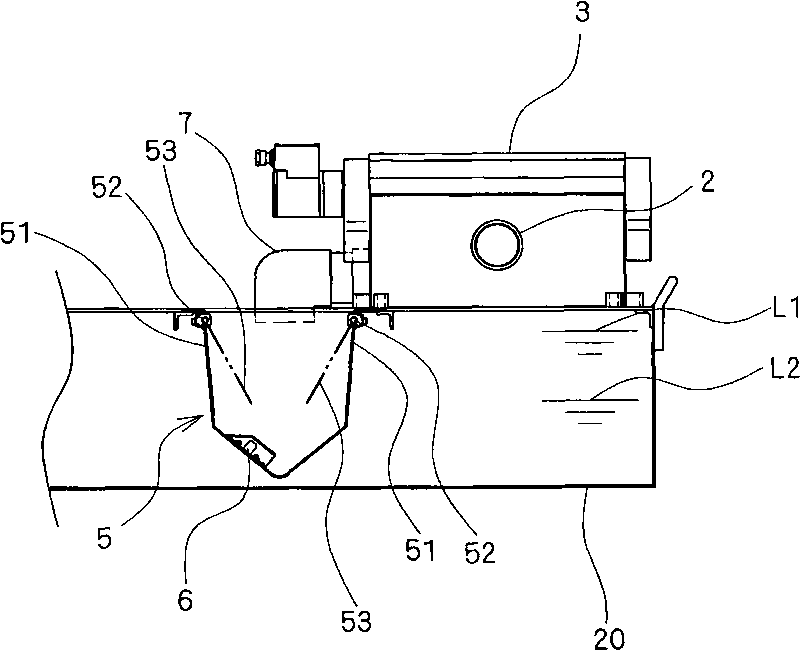

[0049] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. figure 1 It is a schematic diagram showing the structure of the machine tool coolant purification device in the embodiment of the present invention. Such as figure 1 As shown, the coolant purification device for machine tools in this embodiment purifies the coolant in two stages.

[0050] First, the used coolant generated by the machine tool 1 is sent to the magnetic separation device 3 via the primary supply line 2 . In the magnetic separator 3 , grinding dust etc. which are magnetic bodies are mainly separated and recovered.

[0051] Next, the coolant from which the magnetic substance has been mainly removed in the magnetic separation device 3 is sent to a non-magnetic substance separation and filtration device (for example, a cyclone type removal device) 10 via a secondary supply line 4 . The non-magnetic material separation and filtration device 10 remove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com