Elevator cable inspection system

A technology for inspection systems and steel cables, which can be used in transportation and packaging, elevators, etc., and can solve the problems of complex structure of steel cables and rising manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

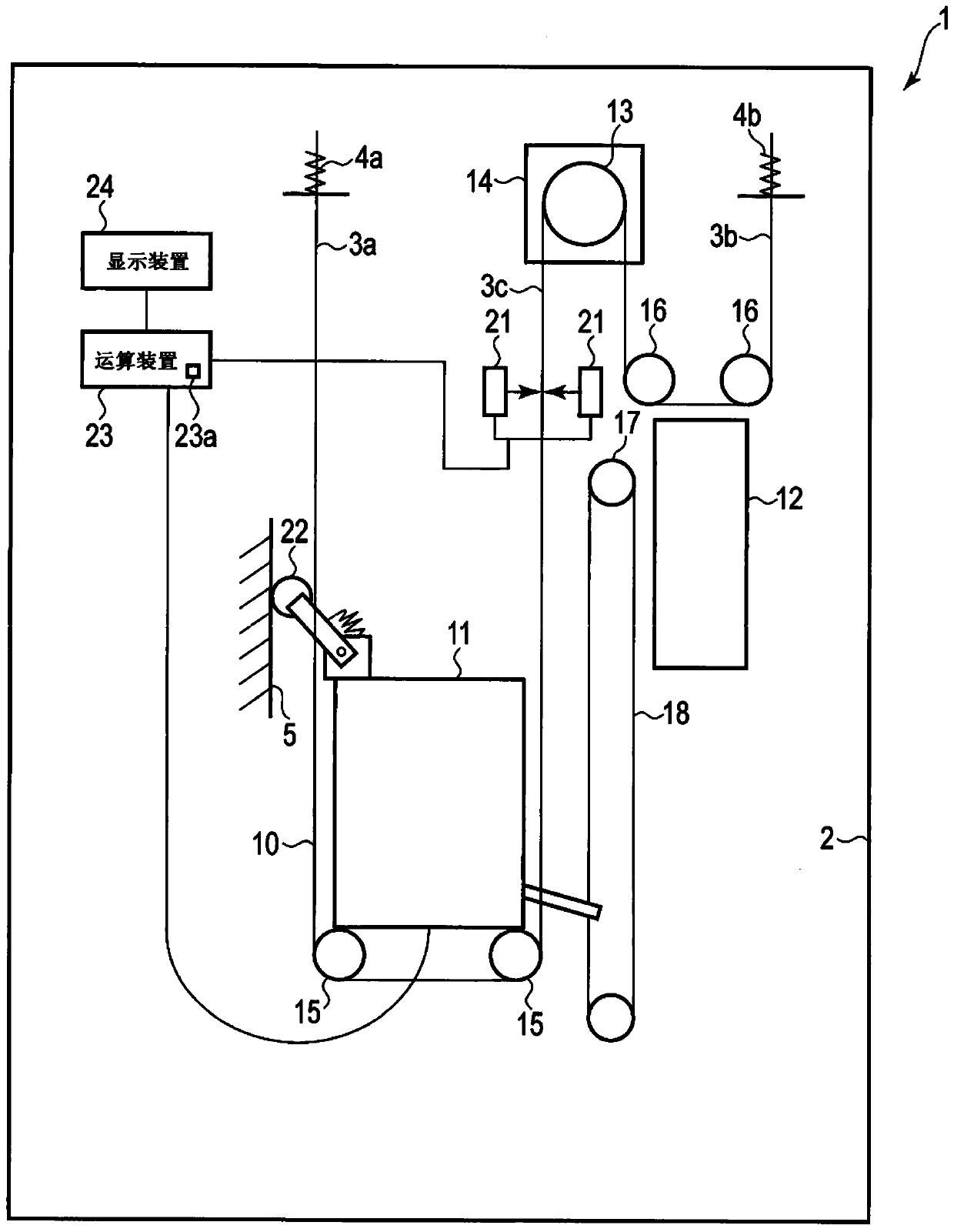

[0023] figure 1 It is a figure showing the schematic structure of the machine-room-less elevator of 1st Embodiment.

[0024] The elevator 1 has a hoistway 2 installed in a building, and a car 11 and a counterweight 12 are supported inside the hoistway 2 so as to be movable up and down via guide rails. Furthermore, a hoist 14 having a traction sheave 13 is installed on the upper portion of the hoistway 2 .

[0025] The car 11 and the counterweight 12 are suspended in the hoistway 2 via a plurality of main steel cables 10 . Furthermore, figure 1 Only one main steel cable 10 is shown in the figure, and the illustration of other main steel cables 10 is omitted.

[0026] The one end 3a and the other end 3b of the main wire rope 10 are fixed to the upper end of the hoistway 2 via rope locks 4a, 4b, respectively. In addition, the intermediate portion 3 c of the main wire rope 10 is continuously wound around a pulley 15 provided on the car 11 , a traction sheave 13 provided on the...

no. 2 Embodiment approach

[0080] Next, a second embodiment will be described.

[0081] In the above-mentioned first embodiment, the encoder 22 is provided on the car 11, and the pulse signal output from the encoder 22 is counted. A rotary encoder is used as the encoder 22, but a linear encoder (not shown) that magnetically or optically outputs pulses in the hoistway 2 along the ascending and descending direction of the car 11 may also be used.

[0082] Here, as the pulse generating unit, as long as it has a structure that generates a pulse signal substantially synchronously with the feeding amount of the main steel cable 10, that is, as long as it generates a pulse signal as the car 11 and the counterweight 12 move up and down. structure, the effect is the same. Therefore, the existing encoder installed in the elevator 1 for detecting the car position and speed can be used.

[0083] Next, the configuration in the case where an existing encoder is used as the pulse generator of this system will be des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com