Environment-friendly dispersing agent for dyeing in one bath

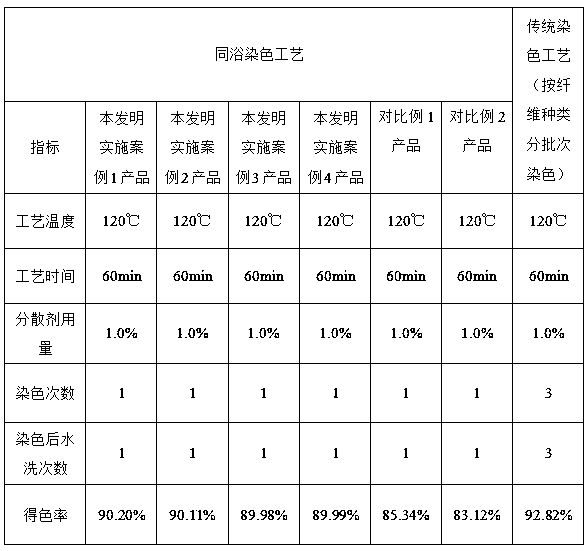

A dispersant and environmentally friendly technology, applied in the field of fabric dyeing, can solve the problems of many processes, uneven dyeing, error-prone, etc., and achieve the effect of improving economic benefits, improving economic effects, and avoiding color flowers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0024] An environment-friendly dyeing bath dispersant is characterized in that by mass percentage, its composition is as follows:

[0025] Lauryl alcohol polyoxyethylene ether: 15%

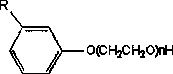

[0026] Vegetable cardanol ethoxylates: 10%

[0027] Diatomaceous earth: 5%

[0028] Emulsifying thickening dispersant (polyacrylamide isoparaffin lauryl ether): 0.5%

[0029] water: balance

[0030] The environmentally friendly preparation method is as follows: Weigh lauryl alcohol polyoxyethylene ether, plant cardanol polyoxyethylene ether, diatomaceous earth, emulsifying thickening and dispersing agent respectively according to the mass percentage, and then put them into the reaction kettle, add water , heat up to 50°C, stir well and evenly to get an environment-friendly dyeing bath dispersant.

Embodiment example 2

[0032] An environment-friendly dyeing bath dispersant is characterized in that by mass percentage, its composition is as follows:

[0033] Stearyl polyoxyethylene ether: 5%

[0034] Plant cardanol polyoxyethylene ether: 15%

[0035] Organic bentonite: 10%

[0036] Emulsifying thickening dispersant (polyacrylamide isoparaffin lauryl ether): 1%

[0037] water: balance

[0038] The preparation method is the same as that of Example 1.

Embodiment example 3

[0040] An environment-friendly dyeing bath dispersant is characterized in that by mass percentage, its composition is as follows:

[0041] Lauryl alcohol polyoxyethylene ether: 15%

[0042] Vegetable cardanol ethoxylates: 10%

[0043] Nano silica: 5%

[0044] Emulsifying thickening dispersant (polyacrylamide isoparaffin lauryl ether): 0.2%

[0045] water: balance

[0046] The preparation method is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com