Screening system for microbial strains with different keratin degradation capabilities

A technology of keratin degradation and microbial strains, which is applied in the field of screening system of microbial strains with different keratin degradation capabilities, can solve problems such as inconclusiveness, and achieve the effect of simple steps, short cycle and strong repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1 Implementation materials

[0025] Microbial species: Stenotrophomonas maltophilia DHHJ, a bacterium that degrades feathers;

[0026] Feather powder: Wash the chicken feathers with detergent, dry them at 80°C for 48 hours, shred them and crush them with a pulverizer.

Embodiment approach

[0028] 2.1 Choose the right feather powder plate

[0029] Prepare different feather meal concentrations, the feather meal plates of agar concentrations, as shown in Table 1:

[0030] Table 1 Composition of the initial feather meal flat plate (100mL)

[0031]

[0032] After high temperature and high pressure sterilization, the feather meal is unevenly distributed in the medium and is easy to agglomerate. After being cultured by dropping the bacterial solution, the contrast between the bacteria and the plate is low, and it is difficult to observe the growth of the bacteria. In order to solve the above problems, the feather meal plate was improved. recipes such as figure 2 shown.

[0033] Feather meal flat plate composition (100mL) after the improvement of table 2

[0034]

[0035] Feather powder is evenly distributed in the culture medium without agglomeration. After being cultured by dropping the bacterial solution, the contrast between the bacteria and the plate is h...

Embodiment 2

[0046] (1) The preparation of feather meal flat plate: get the feather meal 1g that embodiment 1 obtains, glucose 1g, potassium chloride 0.04g, sodium chloride 0.03g, Tween 80 0.4g, agar 2g, disodium hydrogen phosphate 0.4g, Potassium dihydrogen phosphate 0.03g, pH = 7.5 to prepare a feather meal flat plate.

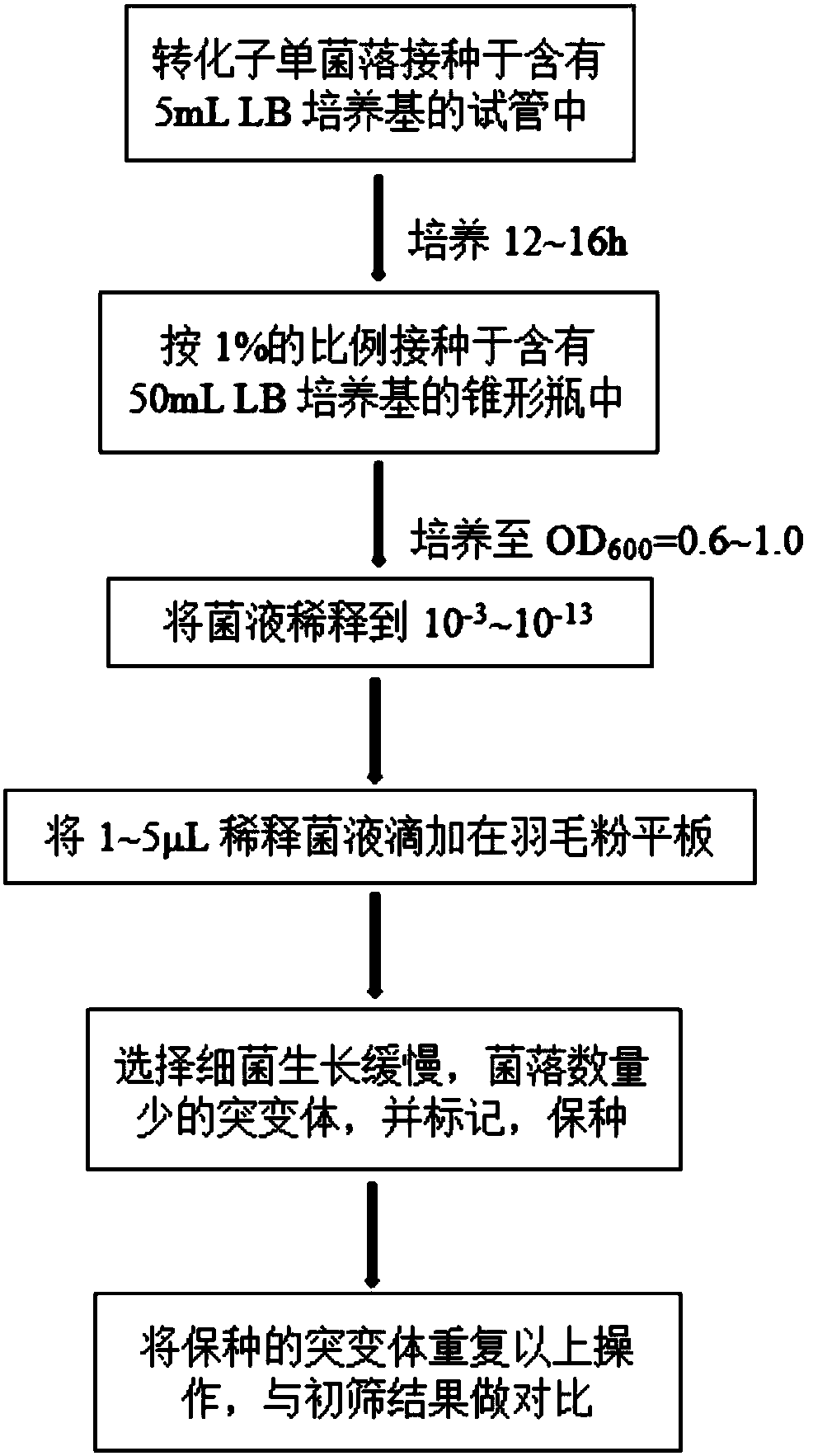

[0047] (2) Cultivation of the second-generation bacterial liquid of the transformant: Inoculate Stenotrophomonas maltophilia DHHJ on a feather meal plate, pick a single colony of the microorganism to be identified, inoculate it in a test tube containing 5mL of beef extract peptone medium, and place it at 35°C, 160rpm Cultivate for 12 to 16 hours to obtain the transformant bacterial liquid, inoculate 500 μL of the bacterial liquid from the above-mentioned test tube into an Erlenmeyer flask containing 50 mL of beef extract peptone medium according to the inoculation ratio of 1%, and culture it at 35°C and 160 rpm until OD 600 =0.6, the second-generation bacterial liquid of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com