Process for preparing cryolite by using HF (hydrogen fluoride) waste liquid and cryolite prepared through process

A technology of cryolite and waste liquid, which is applied in the direction of aluminum fluoride and aluminum halide, can solve the problems of increasing environmental pollution load, secondary pollution, waste sludge, etc., and achieves easy operation and realization, high safety factor and low energy consumption low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

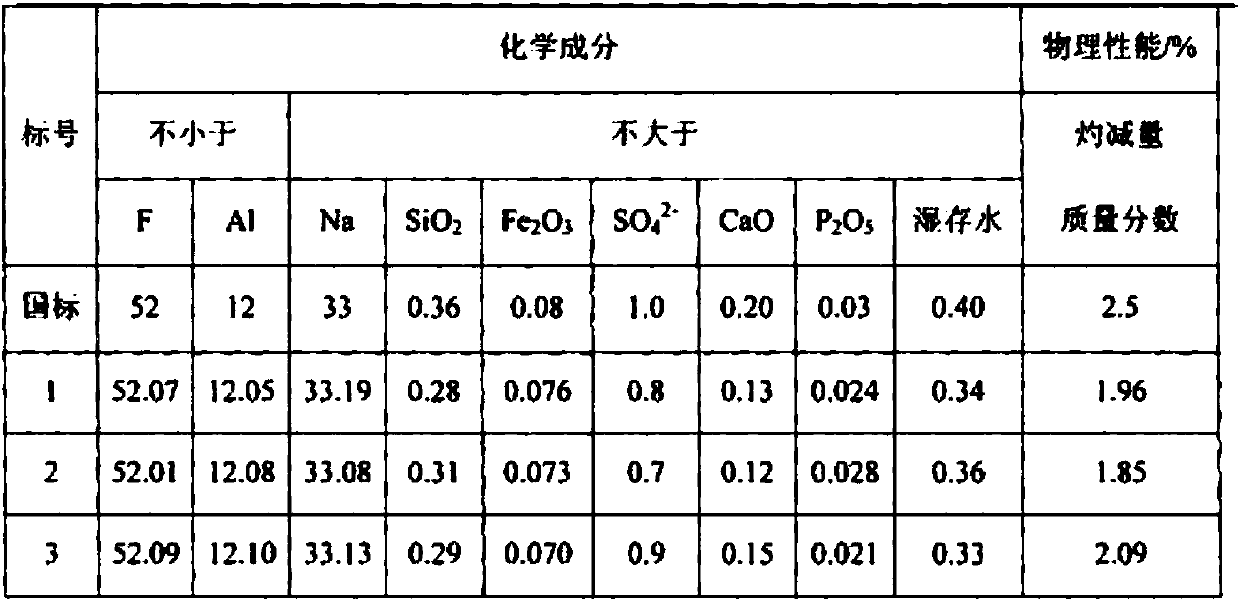

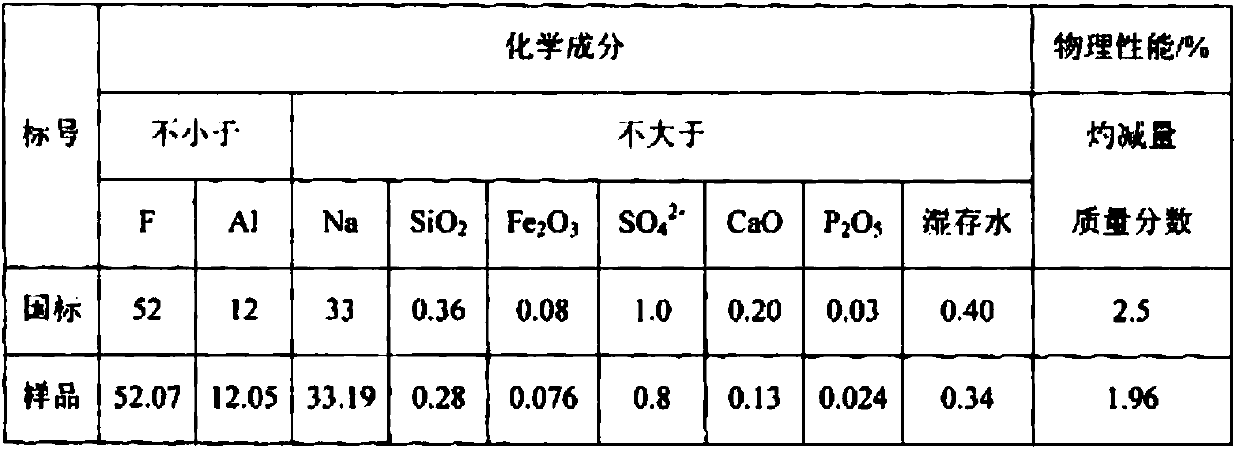

Embodiment 1

[0038] A kind of technology that utilizes HF waste liquid to prepare cryolite, described preparation technology comprises the steps:

[0039] Step 1, taking liquid: take HF waste liquid and send it to a first-class reaction kettle resistant to acid and alkali corrosion;

[0040] Step 2, adjust the pH: add alkali to the HF waste liquid in the liquid taken in step 1, and adjust the pH of the mixed liquid to 8;

[0041] Step 3, one-time stirring: the mixed solution obtained by adjusting the pH value in step 2 was stirred at room temperature for 0.5 hours;

[0042] Step 4, primary filtration: the mixed solution obtained by stirring in step 3 is sent to a filter for filtration, the filter cake is discarded, and the filtrate is retained for subsequent use;

[0043] Step 5, feeding: first detect the concentration of F in the filtrate obtained by filtering for the first time in step 4, then add aluminum salt and sodium salt in the filtrate, and control the molecular ratio of F-, alum...

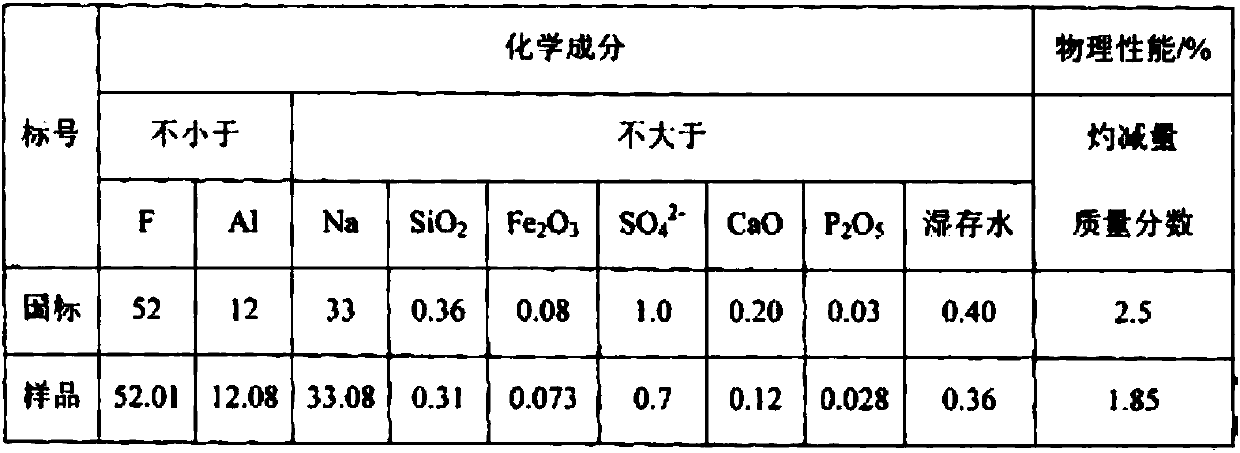

Embodiment 2

[0066] A kind of technology that utilizes HF waste liquid to prepare cryolite, described preparation technology comprises the steps:

[0067] Step 1, taking liquid: take HF waste liquid and send it to a first-class reaction kettle resistant to acid and alkali corrosion;

[0068] Step 2, adjust the pH: add alkali to the HF waste liquid in the liquid taken in step 1, and adjust the pH of the mixed liquid to 9;

[0069] Step 3, one-time stirring: the mixed solution obtained by adjusting the pH value in step 2 was stirred at room temperature for 3 hours;

[0070] Step 4, primary filtration: the mixed solution obtained by stirring in step 3 is sent to a filter for filtration, the filter cake is discarded, and the filtrate is retained for subsequent use;

[0071] Step 5, feeding: first detect the concentration of F in the filtrate obtained by filtering for the first time in step 4, then add aluminum salt and sodium salt in the filtrate, and control the molecular ratio of F-, alumin...

Embodiment 3

[0094] A kind of technology that utilizes HF waste liquid to prepare cryolite, described preparation technology comprises the steps:

[0095] Step 1, taking liquid: take HF waste liquid and send it to a first-class reaction kettle resistant to acid and alkali corrosion;

[0096] Step 2, adjust the pH: add alkali to the HF waste liquid in the liquid taken in step 1, and adjust the pH of the mixed liquid to 10;

[0097] Step 3, one-time stirring: the mixed solution obtained by adjusting the pH value in step 2 was stirred at room temperature for 6 hours;

[0098] Step 4, primary filtration: the mixed solution obtained by stirring in step 3 is sent to a filter for filtration, the filter cake is discarded, and the filtrate is retained for subsequent use;

[0099] Step 5, feeding: first detect the concentration of F in the filtrate obtained by filtering for the first time in step 4, then add aluminum salt and sodium salt in the filtrate, and control the molecular ratio of F-, alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com