Screw rod weightless type material discharging machine based on neural network and controller of screw rod weightless type material discharging machine

A neural network and cutting machine technology, which is applied in the field of screw loss-in-weight material cutting machine and its controller, can solve the problems that cutting cannot be directly applied, the effect of weight loss is not considered, and high-precision cutting cannot be satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

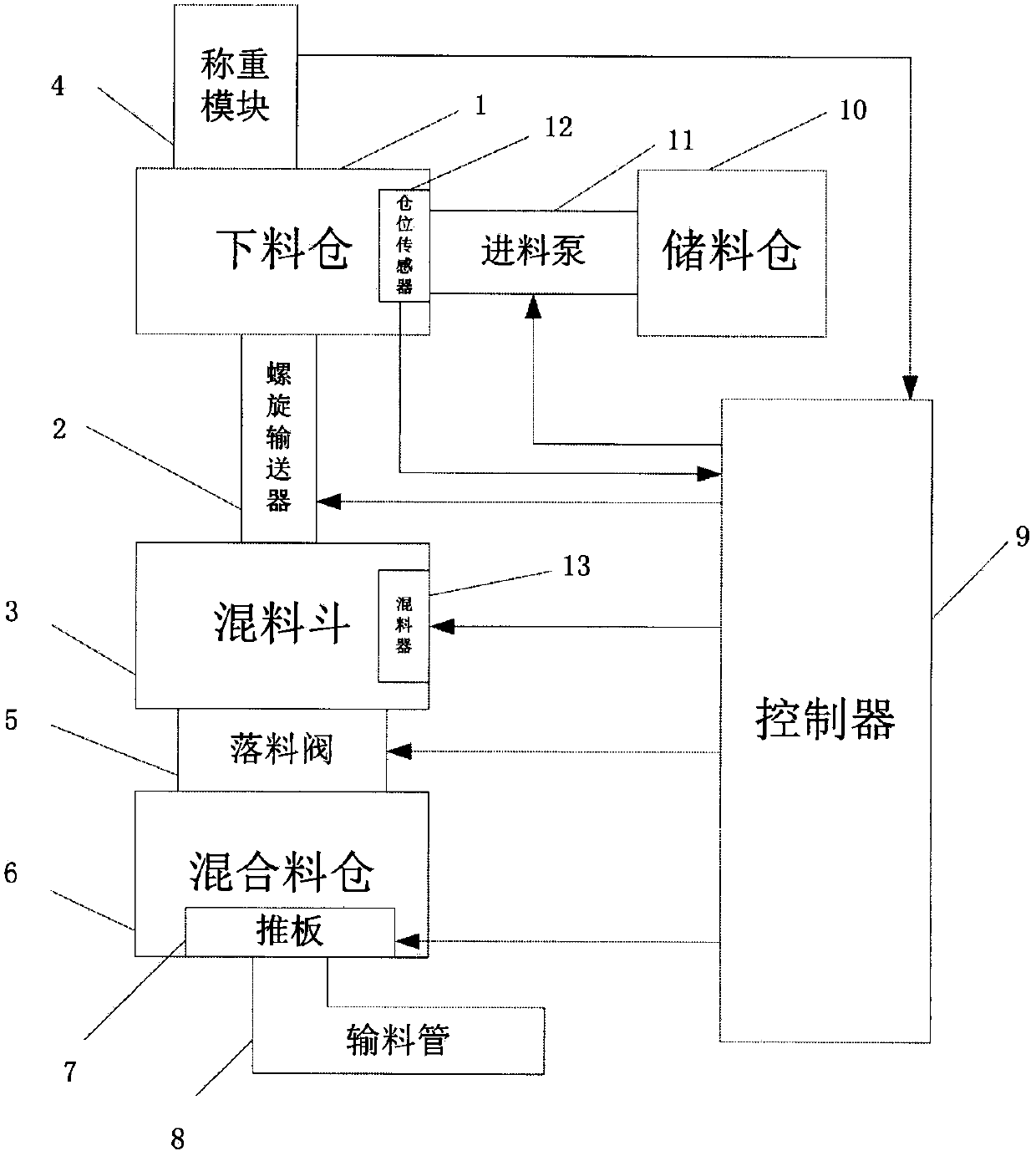

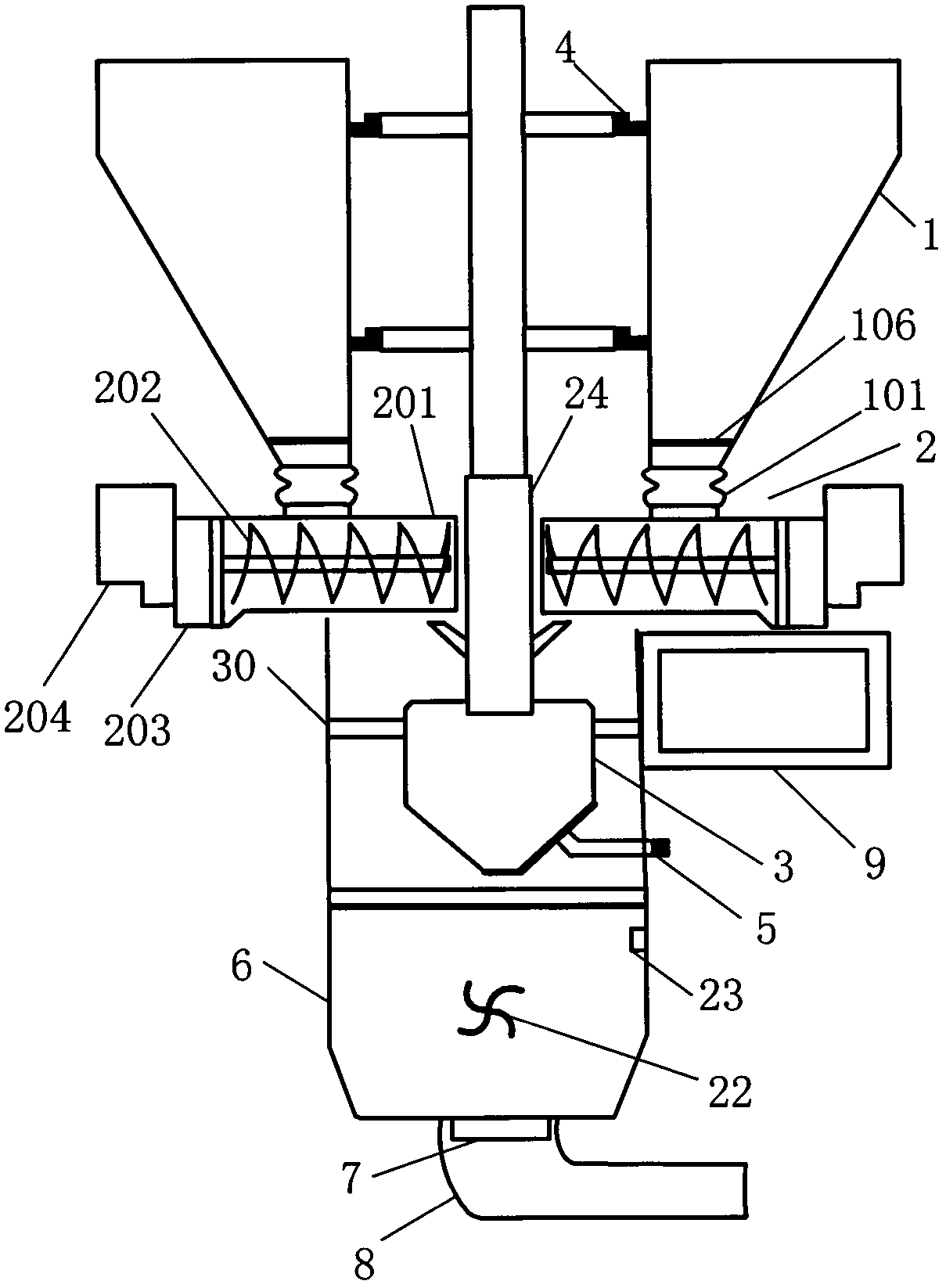

[0072] Such as figure 1 with figure 2 As shown, the screw loss-in-weight type material feeding machine based on neural network of the present invention includes feeding bin 1, screw conveyor 2, mixing hopper 3, weighing module 4, blanking valve 5, mixing bin 6 and controller 9. There is a set of feed bin 1 corresponding to screw conveyor 2 for each component of material. Commonly used component categories are 2 to 6 types, and component categories can also be added as needed.

[0073] There is a pumping plate 106 at the bottom of the lower bin 1. The screw conveyor 2 includes a screw box 201, a conveying screw 202, a connector 203 and a motor 204. The shell of the motor 204 is connected with the screw box 201 through the connector 203 and is located in the screw box 201. The conveying screw 202 is connected to the shaft of the motor 204 through a shaft sleeve; there is a feeding port on the upper surface of the screw box 201 relative to the opening at the bottom of the lower...

Embodiment 2

[0156] combine figure 2 with Figure 12 As shown, when the multi-component material falls into the mixing hopper 3, the mixer in the mixing hopper 3 acts to mix the materials evenly. Such as Figure 12 As shown, the mixer 13 includes a mixing shaft 137 fixed in the mixing hopper, a mixing turntable 138 and a spiral blade 139 installed on the mixing shaft 137, and a mixing bracket 136 fixed on the inner wall of the mixing hopper 3 is used. To support the mixing shaft 137. Mixing turntable 138 is similar to the ring shape of a waterwheel, and its outer ring has rectangular blades that are substantially perpendicular to the circumference, and holes can be opened on the blades. The helical blade 139 adopts an irregular helical blade, and holes are distributed on the blade.

[0157] There is an arc-shaped wedge 301 on the inner side of the openable assembly at the bottom opening of the mixing bin 3. Under the action of the controller, the mixing shaft 137 of the mixer 13 rotates...

Embodiment 3

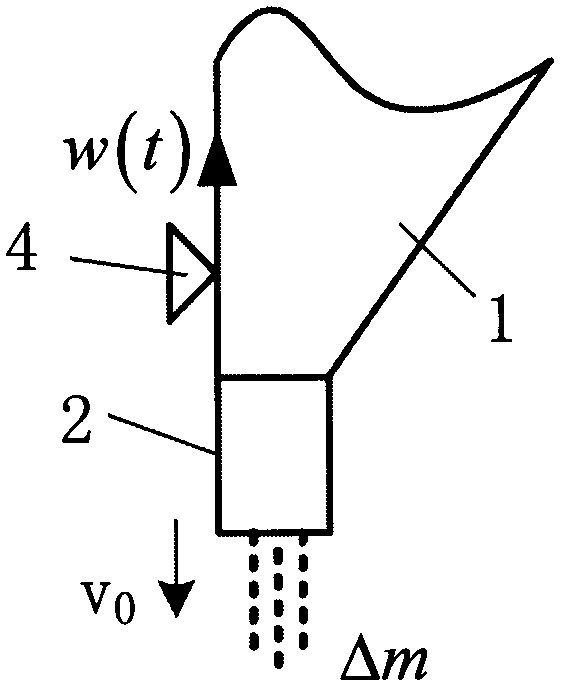

[0160] combine figure 2 As shown, in order to measure the weight loss of the lower silo 1, two horizontal support parts can be drawn from the outer wall of the lower silo; the weighing module is placed horizontally, and the weighing module supports the lower silo vertically from both sides. Or lead out two suspension parts from the top of the lower silo 1, place the weighing module horizontally, and support the lower silo vertically from both sides of the weighing module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com