Paper box forming machine capable of performing deep box wrapping

A deep-packing and forming machine technology, applied in packaging, papermaking, transportation and packaging, etc., can solve the problems of waste of raw materials, poor packaging effect, and impact on production quality, and achieve the effect of improving production efficiency, saving costs and saving time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

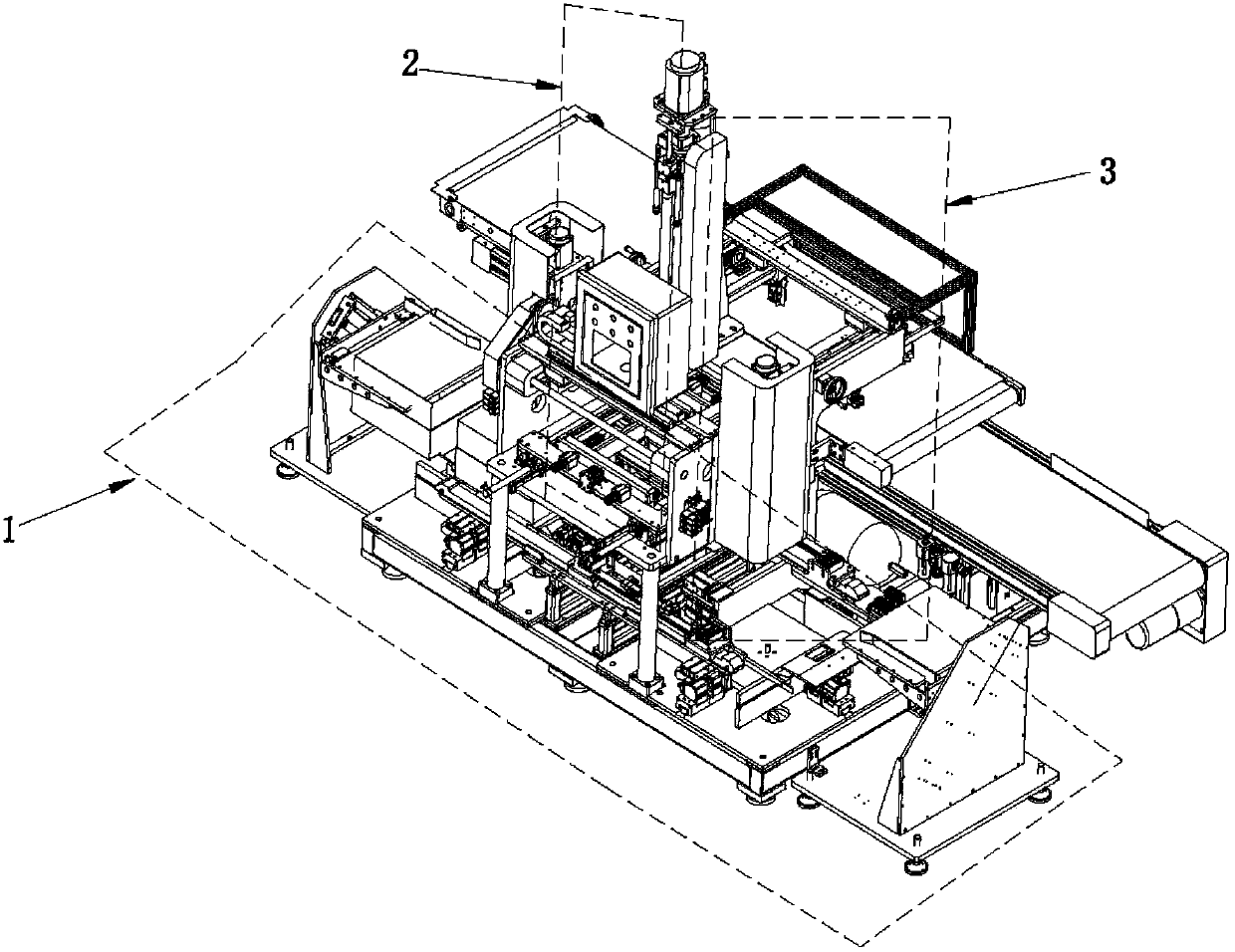

[0026] One of the specific embodiments of a carton forming machine capable of deep wrapping of the present invention includes a box dividing mechanism 2, and an edge brushing mechanism 1 is arranged on the top of the box dividing mechanism 2, and the front and rear sides of the edge brushing mechanism 1 Both sides are respectively provided with wrapping mechanism 3, and these edge brushing mechanism 1 and box separating mechanism 2 are all generally used in the carton forming machine, promptly belong to prior art, and its internal procedure is also prior art, and specifically can refer to current The carton forming machine that has been disclosed, such as Chinese Patent No. 201621226908.5, the patent name is a fully automatic edge brushing and box-packing machine, which can be used as an example to improve this embodiment by referring to the currently disclosed embodiments. Be specific.

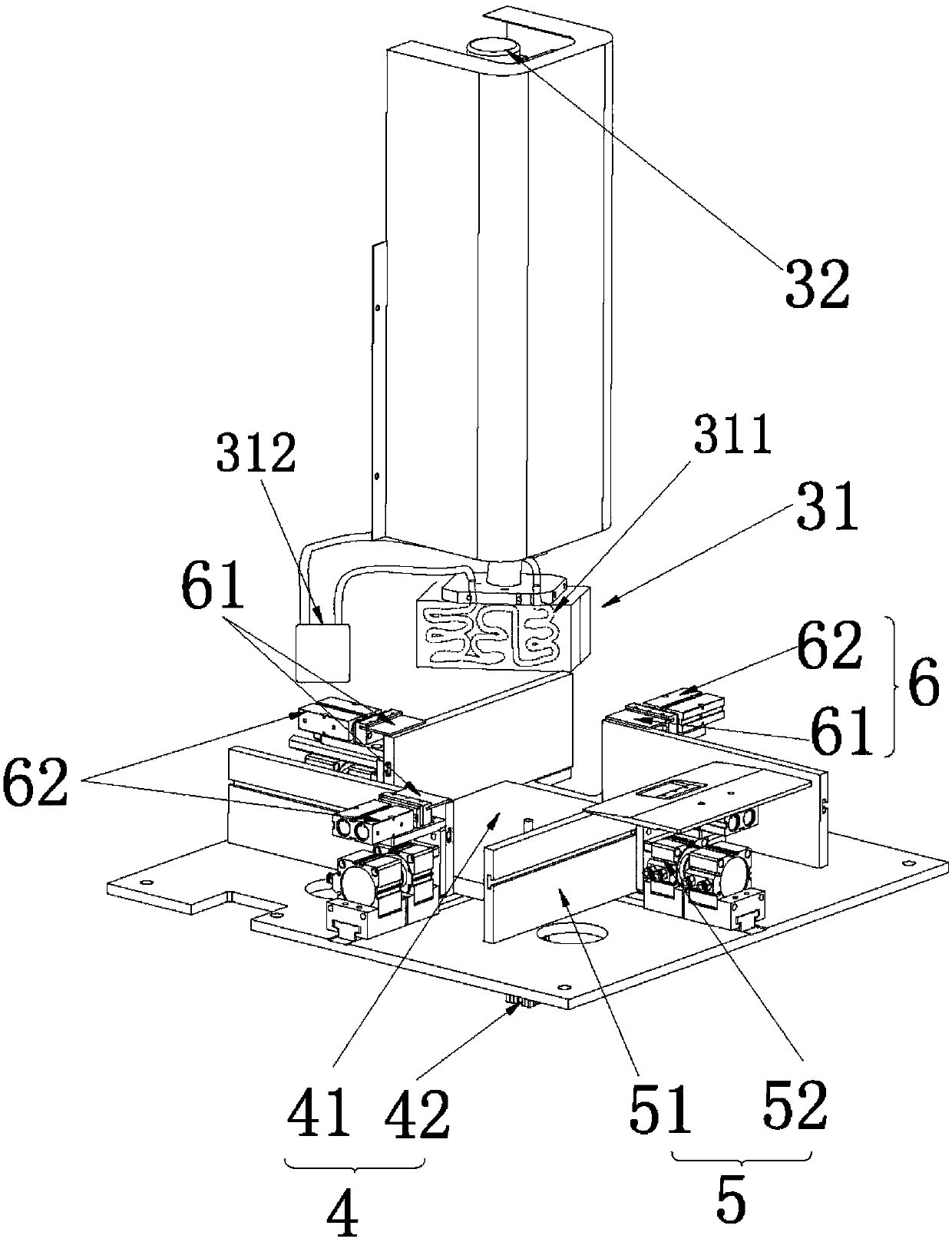

[0027] As an improved part of the carton forming machine of this embodiment, the specific...

Embodiment 2

[0037] The second specific embodiment of a carton forming machine capable of deep wrapping of the present application, the main technical solution of this embodiment is the same as that of embodiment 1, and the features not explained in this embodiment are adopted in embodiment 1 explanation, and will not repeat them here. The difference between this embodiment and Embodiment 1 is that the heating device includes a heating wire and a heating controller, the heating wire is arranged inside the box die head, the heating wire (not shown in the figure) and the heating controller (not shown in the figure) ) electrical connection, used to control the heating of the heating wire and the touch head of the heating pack box. The heating wire is energized and self-heating, and then the outer surface of the box-packing die 31 itself is heated, so that the process of removing air bubbles can be performed during the box-packing process, which solves the need to transfer the carton to anothe...

Embodiment 3

[0039] The third specific embodiment of a carton forming machine capable of deep wrapping of the present application, the main technical solution of this embodiment is the same as that of embodiment 1, and the features not explained in this embodiment are adopted in embodiment 1 explanation, and will not repeat them here. The difference between this embodiment and Embodiment 1 is that the heating device includes a heat exchange channel and a thermal oil pump. Out) connected, used to supply heat oil to the heat exchange channel to heat the package die. The hot oil pump provides hot oil flow for the heat exchange channel opened in the box-packing die 31, so that the outer surface of the box-packing die 31 itself can exchange heat with the hot oil, so that the air bubbles can be removed during the box-packing process. The process operation solves the problem that the carton needs to be transferred to another debubbling device for the debubbling process in the past, which improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com