A high-efficiency catalyst fine grinding device for chemical experiments

A chemical experiment and fine grinding technology, applied in the field of chemistry, can solve the problems of inability to screen catalysts, time-consuming and laborious grinding, slow grinding speed, etc., and achieve the effect of reducing the difficulty of cleaning, high grinding efficiency, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

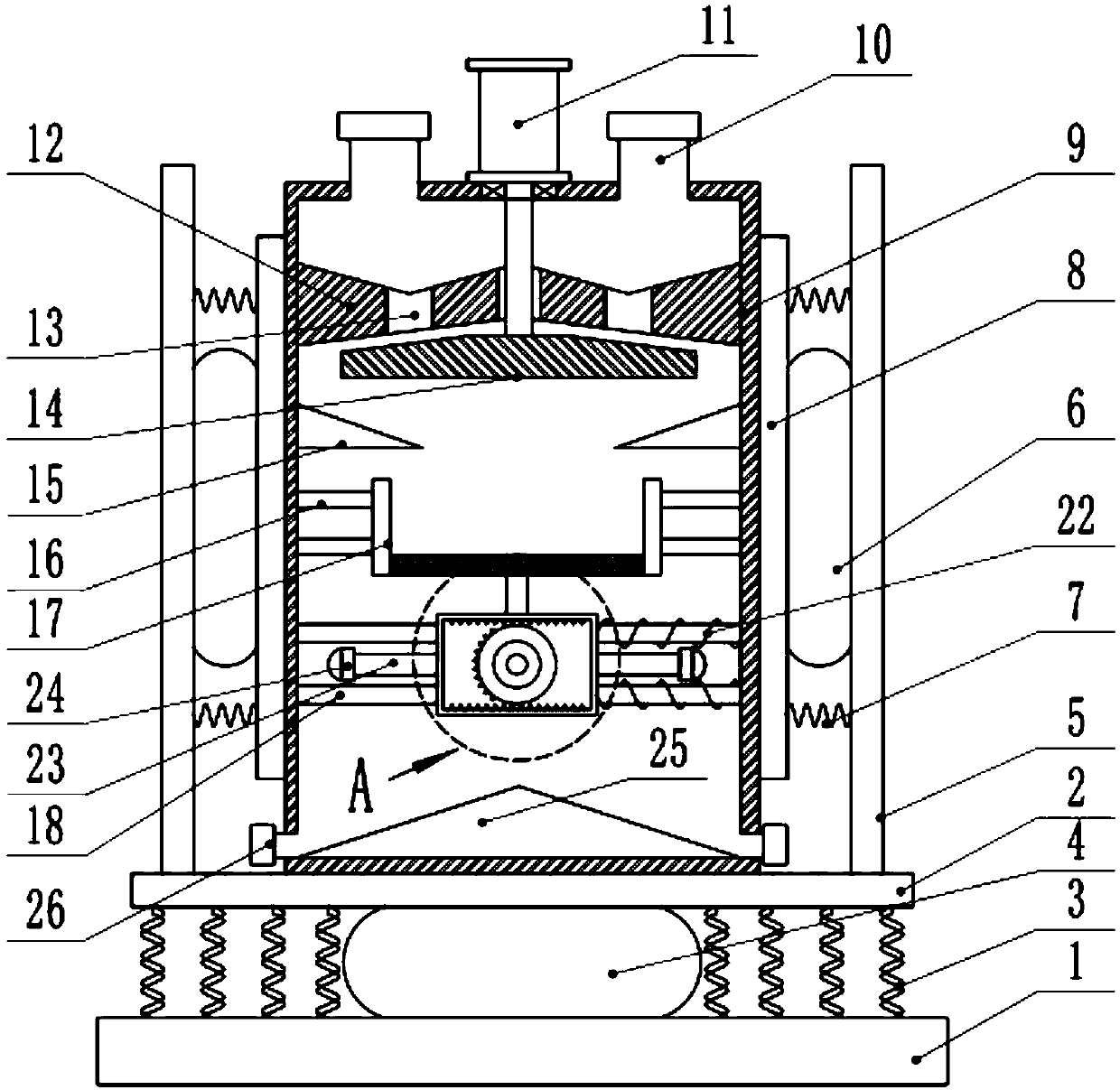

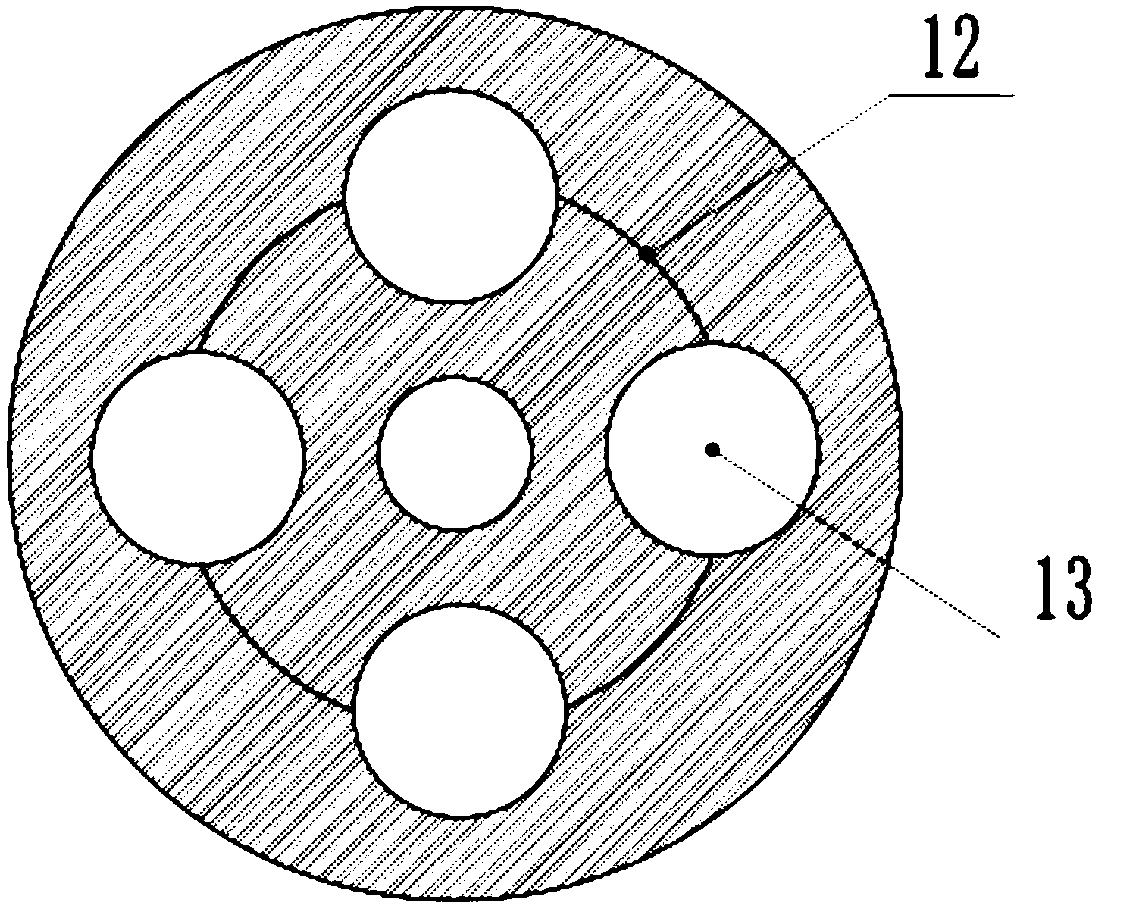

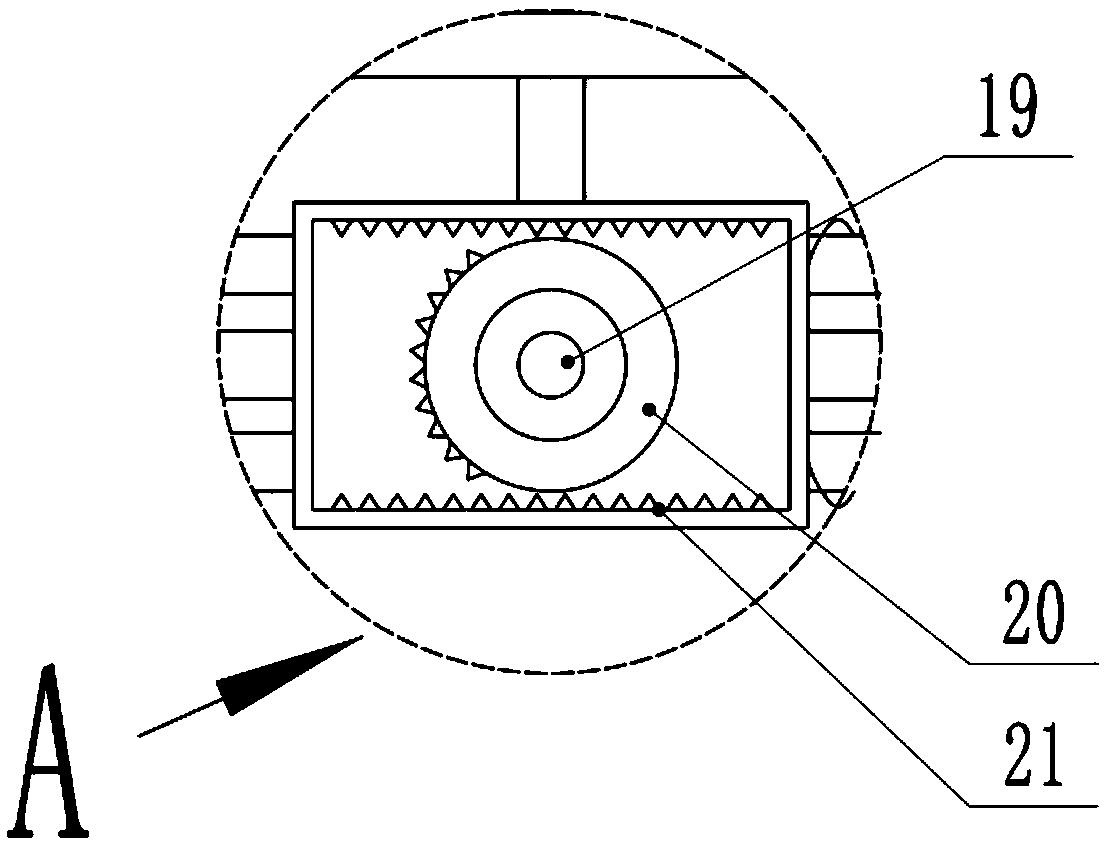

[0022] see Figure 1-3 , a high-efficiency catalyst fine grinding device for chemical experiments, comprising a shock absorbing plate 2, a shock absorbing spring A3, a grinding box 9, a fixed grinding disc 12, a rotating grinding disc 14, a screening box 17, a second drive motor 19, and a moving slide frame 21 And impact head 24, described base 1 top is provided with shock-absorbing plate 2, also is connected with shock-absorbing spring A3 between shock-absorbing plate 2 and base 1, is also provided with elastic air bag A4 between shock-absorbing plate 2 and base 1, The elastic airbag A4 is filled with an inert gas, and through the joint action of the shock-absorbing spring A3 and the elastic airbag A4, a double damping effect is achieved, greatly reducing the vibration noise generated during the grinding process; the left and right sides of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com