ASA high rubber powder drying process conveying equipment

A technology for conveying equipment and high rubber powder, which is applied in the fields of cocoa, grain processing, food science, etc. It can solve the problems of prolonging the production cycle, high failure rate, and small contact area between steam and slurry, so as to reduce the probability of equipment damage, The effect of reasonable tiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

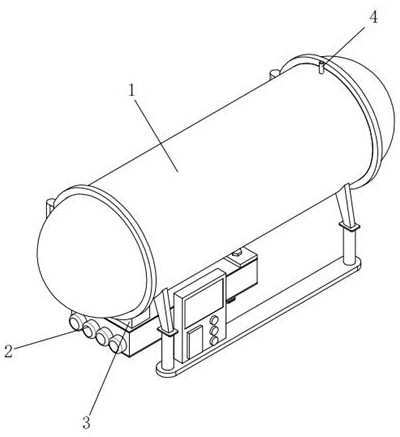

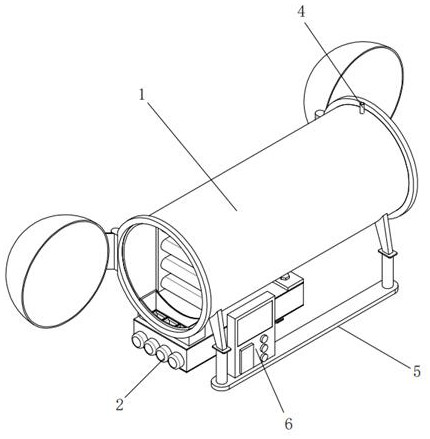

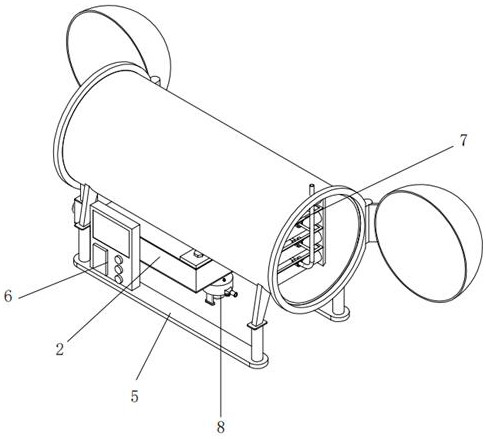

[0032]In the production and manufacturing process of ASA high rubber powder, a kind of ASA high rubber powder drying process conveying equipment provided by the present invention is used to dry and transport ASA high rubber powder. The main drying equipment of this equipment is belt vacuum dryer 1 , Belt vacuum dryer 1 is equipped with multiple vacuum conveyor belts suitable for drying slurry-type materials. After the raw materials are laid flat on the vacuum conveyor belts, they will be dried during the transportation process and will be dried at the other end of the conveyor belts. When discharging, there will be a special guillotine to cut off the connected materials. This is the basic function of the traditional belt vacuum dryer 1. This equipment uses the basic principle and main structure of the traditional belt vacuum dryer 1. And improve the raw material transportation equipment at the feeding end and the finished product transportation equipment at the discharging end,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com