Leveling structure of sludge treatment tank

A sludge treatment and gear technology, which is applied in the field of leveling structure of sludge treatment tanks, can solve problems such as secondary pollution of the living environment, and achieve the effects of saving working time, improving work efficiency and work quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

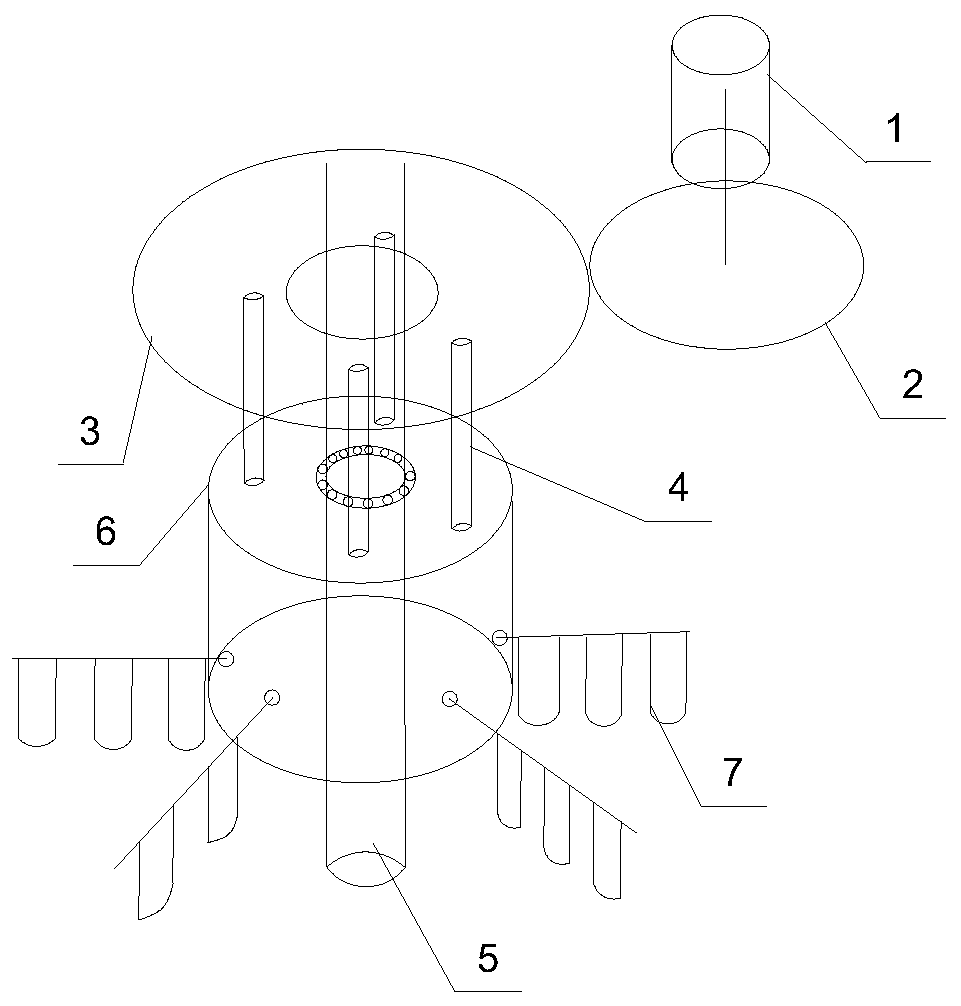

[0025] The following is attached figure 1 The technical solution of the present invention is further described.

[0026] A leveling structure of a sludge treatment tank, used for leveling the sludge in the sludge treatment tank, such as figure 1 Shown, comprise leveling motor 1, first gear 2, second gear 3, feeding shell 5, rotary disc 6 and leveling brush 7. The output end of leveling motor 1 is connected with first gear 2, and first gear 2 meshes with second gear 3. The outer wall of the material feeding shell 5 is connected with the rotating disk 6 through bearings, and several connecting rods 4 are arranged on the circumferential surface of the rotating disk 6, and the tops of several connecting rods 4 are fixedly connected with the bottom surface of the second gear 3, and the second gear 3 Cover the outer wall of the material feeding shell 5, and the center of the second gear 2 is not in contact with the outer wall of the material feeding shell 5. Several leveling brus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com