PWM pulse width type constant current charging type capacitor energy storage welding charging control system

A charging control and capacitive energy storage technology, applied in battery circuit devices, current collectors, electric vehicles, etc., to achieve the effect of eliminating magnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

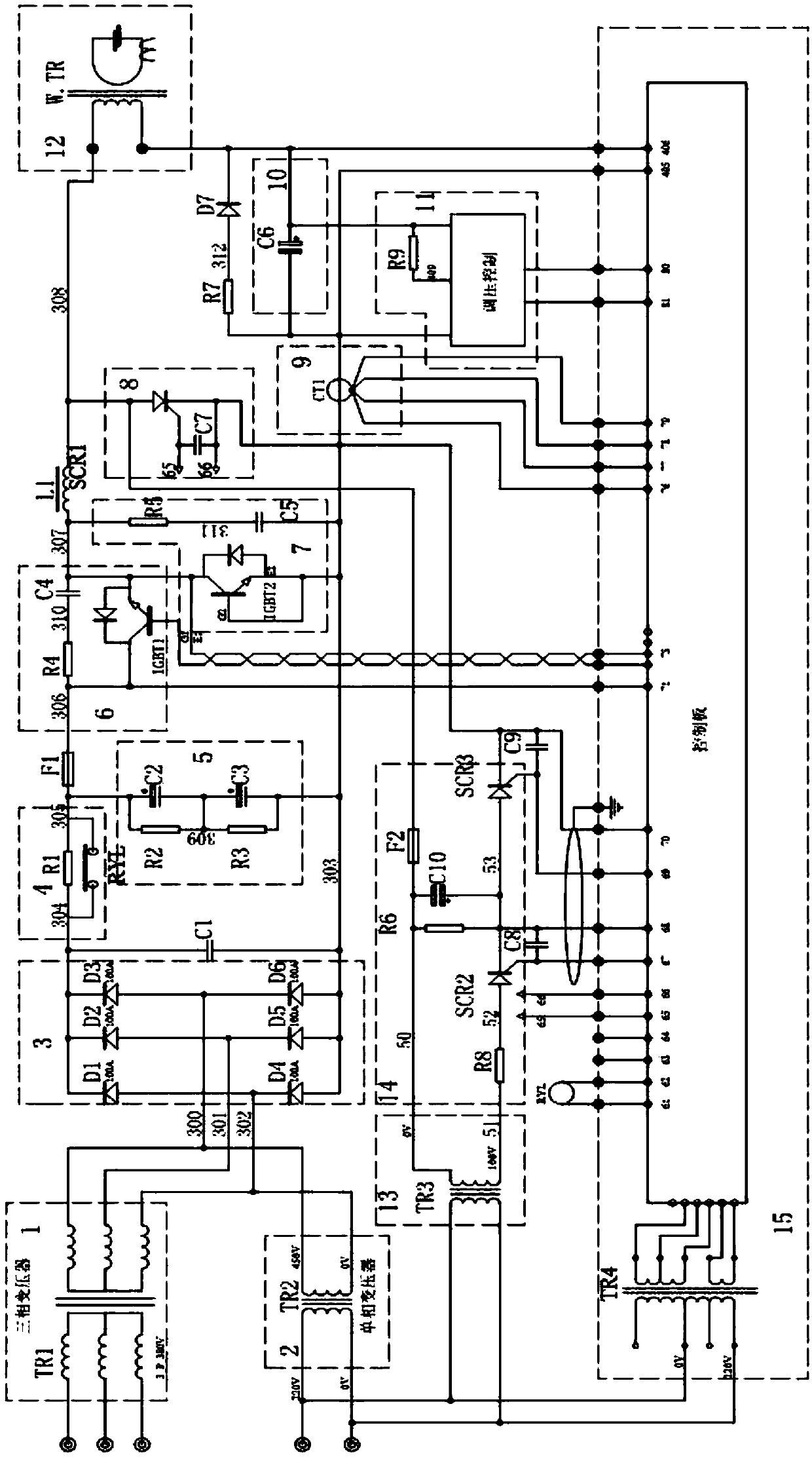

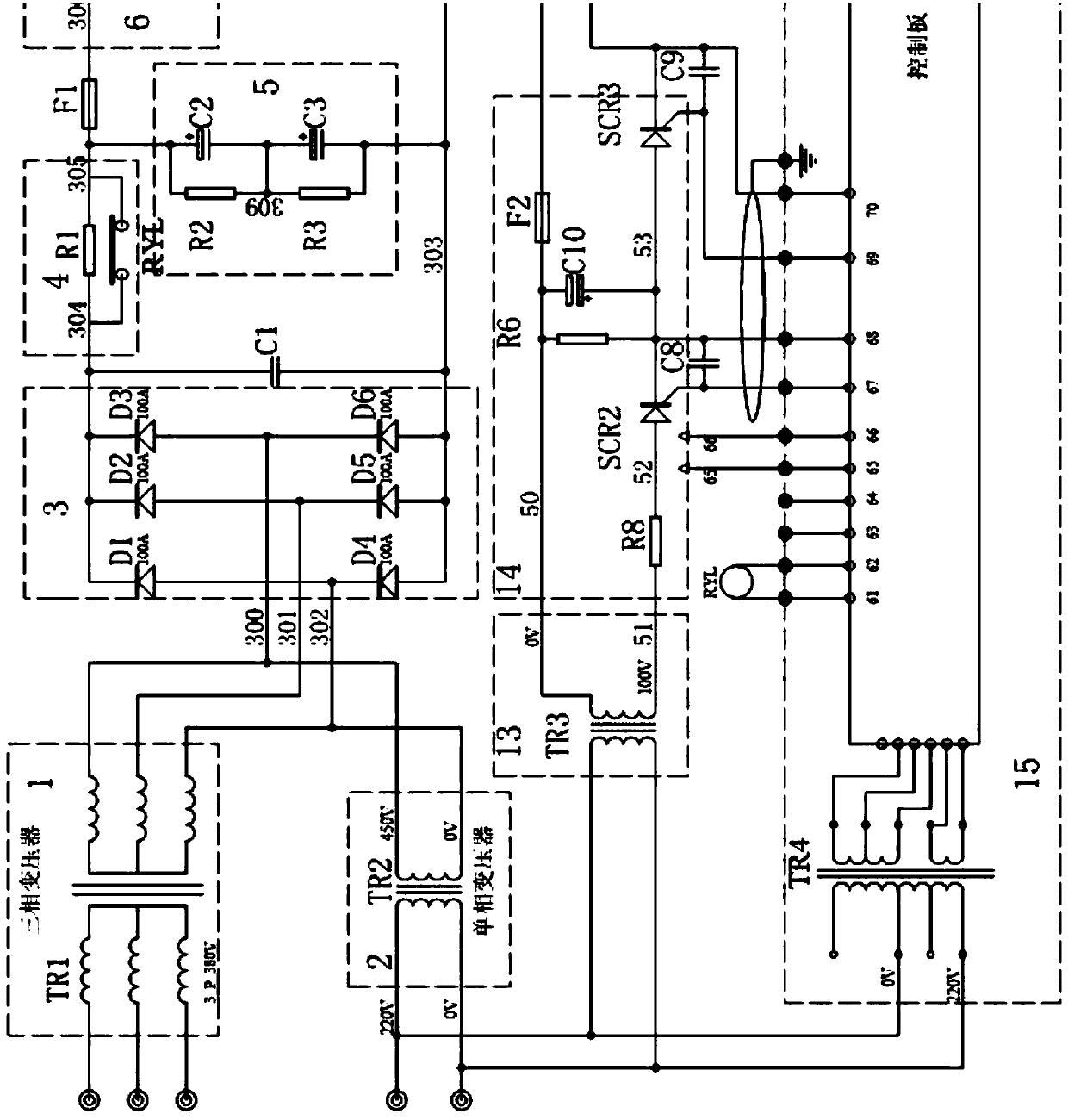

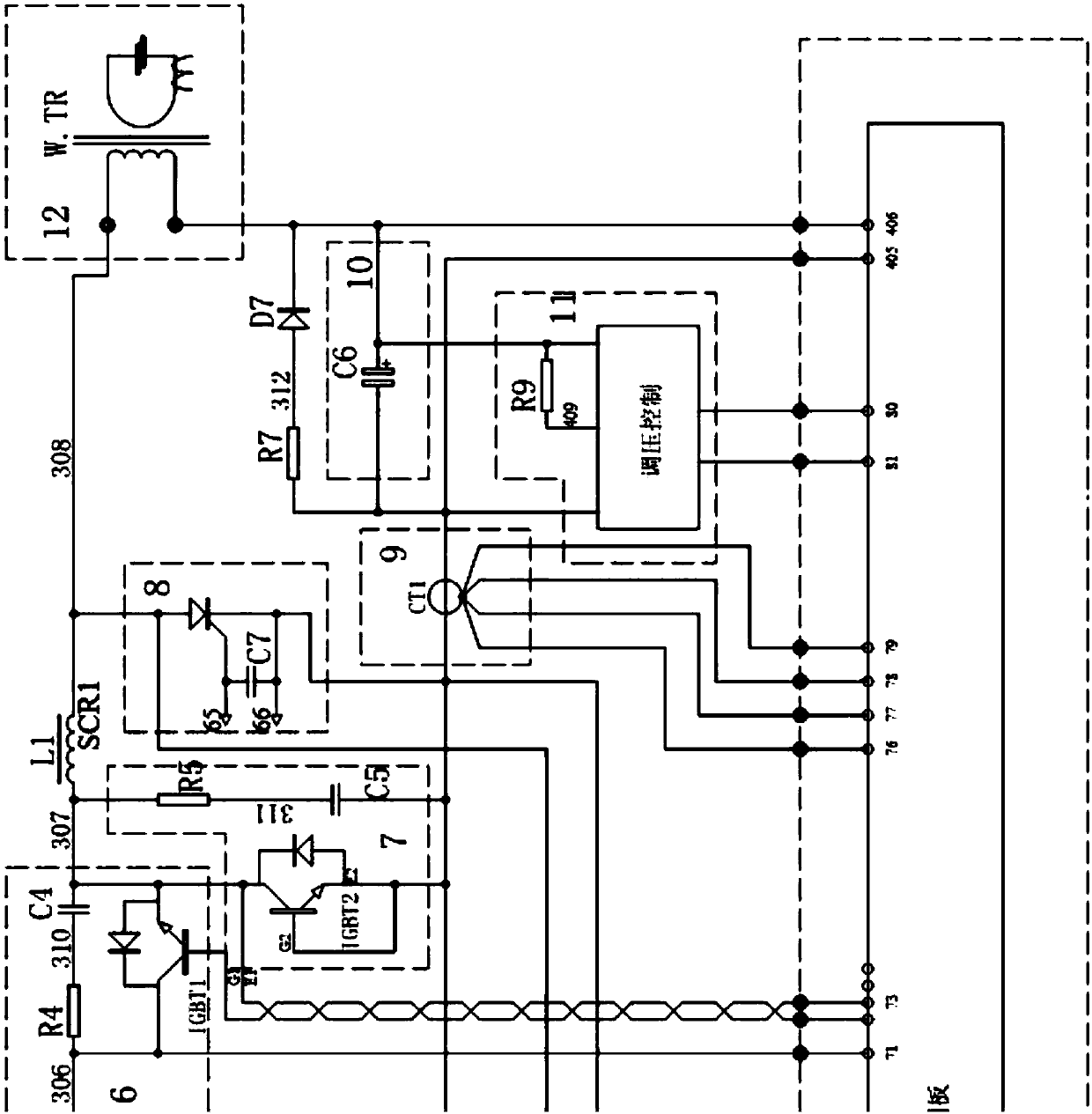

[0039] Such as Figure 1-3 As shown, the PWM pulse width constant current charging type capacitor energy storage welding charging control system includes three-phase charging transformer TR1, single-phase charging transformer TR2, rectification circuit, DC_LINK filter circuit, PWM charging control part, charging current detection part, Welding transformer W.TR, discharge circuit, discharge shutdown circuit, discharge current detection part, discharge control part and capacitor bank.

[0040] The W terminal, U terminal and V terminal of the primary coil of the three-phase charging transformer TR1 are respectively connected to the first phase, the second phase and the third phase of the three-phase electricity, and the two ends of the primary coil of the single-phase charging transformer TR2 Connect the neutral and live wires of the single-phase AC respectively.

[0041] The rectification circuit includes six diodes, wherein the output ends of the fourth diode D4, the fifth dio...

Embodiment 2

[0054] The rectification circuit is provided with four rectification diodes.

Embodiment 3

[0056] The control method of the control system includes the following steps:

[0057] 1. Increase the voltage to the voltage required for charging through a three-phase charging transformer or a single-phase charging transformer;

[0058] 2. Use six (or four) rectifier diodes to form a rectification circuit to convert alternating current into direct current and charge the DC_LINK filter; during initial charging, since the capacitor bank of DC_LINK is in a virtual short circuit state, it is necessary to protect the capacitor bank and charging transformer And the rectification circuit, using the seventh resistor for current-limited charging;

[0059] 3. When the capacitor voltage in the DC_LINK circuit reaches a certain voltage, close the contactor;

[0060] 4. When the contactor is detected to be closed, the charging of the PWM charging control part in the circuit starts to work;

[0061] 5. During the PWM pulse width modulation process, the PWM charging control part uses th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com