Single-anode-electrode double-medium gas source plasma burner

A plasma and dual-medium technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of high power consumption of secondary energy, and achieve the effects of reducing power consumption, improving use efficiency, and simple ignition methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

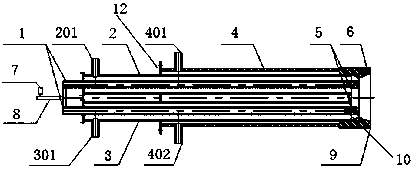

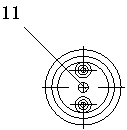

Image

Examples

Embodiment 1

[0039] Embodiment 1: The distance between the air inlet and gas inlet and the arc starting position of the cathode and anode is 800mm, the distance between the inlet and outlet of cooling water and the arc starting position of the cathode and anode is 450mm, and the diameter of the burner sleeve is 150mm. The gas uses air and natural gas as the medium gas respectively, and the design power of the burner is 20kw. In the test results, the thermal power provided by the plasma is 14.3kw, the thermal power provided by combustion is 5.6kw, and the actual operating power is 19.9kw, which is basically the same as the design power. Stable combustion, the air-fuel ratio is controlled between 1:1.01~1.05, the gas flow rate is 50L / min, the cooling water volume is 25L / min, and the cooling water temperature difference is about 1°C.

Embodiment 2

[0040] Embodiment 2: The distance between the air inlet and gas inlet and the arc starting position of the cathode and anode is 800mm, the distance between the cooling water inlet and outlet and the arc starting position of the cathode and anode is adjusted to 600mm, and the diameter of the burner sleeve is 150mm , The gas uses air and natural gas as the medium gas respectively, and the design power of the burner is 20kw. The test results include that the thermal power provided by plasma is 13.5kw, the thermal power provided by combustion is 4.2kw, the actual operating power is 19.2kw, which is 0.8kw different from the designed power, and the temperature after combustion is about 2100°C. Repeated ignition experiment ignition, all can Stable combustion, the air-fuel ratio is controlled between 1:1.01~1.05, the gas flow rate is 50L / min, and the cooling water temperature difference is about 2°C.

Embodiment 3

[0041] Embodiment 3: The distance between the air inlet and gas inlet and the arc starting position of the cathode and anode is 600 mm, the distance between the cooling water inlet and outlet and the arc starting position of the cathode and anode is adjusted to 200 mm, and the diameter of the burner sleeve is 150 mm , The gas uses air and natural gas as the medium gas respectively, and the design power of the burner is 20kw. In the test results, the thermal power provided by the plasma is 14.4kw, the thermal power provided by the combustion is 4.8kw, the actual operating power is 17.7kw, which is 2.3kw different from the design power, and the temperature after combustion is about 2500°C. Repeated ignition experiments can be ignited. Stable combustion, the air-fuel ratio is controlled between 1:1.01~1.05, the gas flow rate is 50L / min, and the cooling water temperature difference is about 0.8°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com