Air channel of engine cylinder cover

A technology of engine cylinders and air passages, applied in engine components, combustion engines, machines/engines, etc., can solve problems such as unsmooth exhaust, inability to increase intake air flow, and inability to fully utilize the performance of the airway structure engine, and achieve optimization. Emissions, improved fuel efficiency and reduced fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

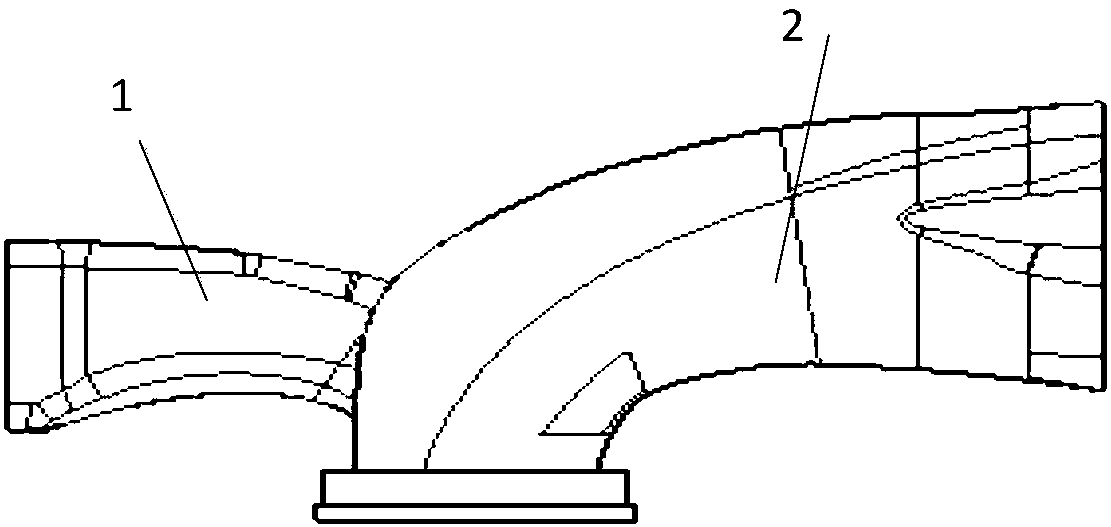

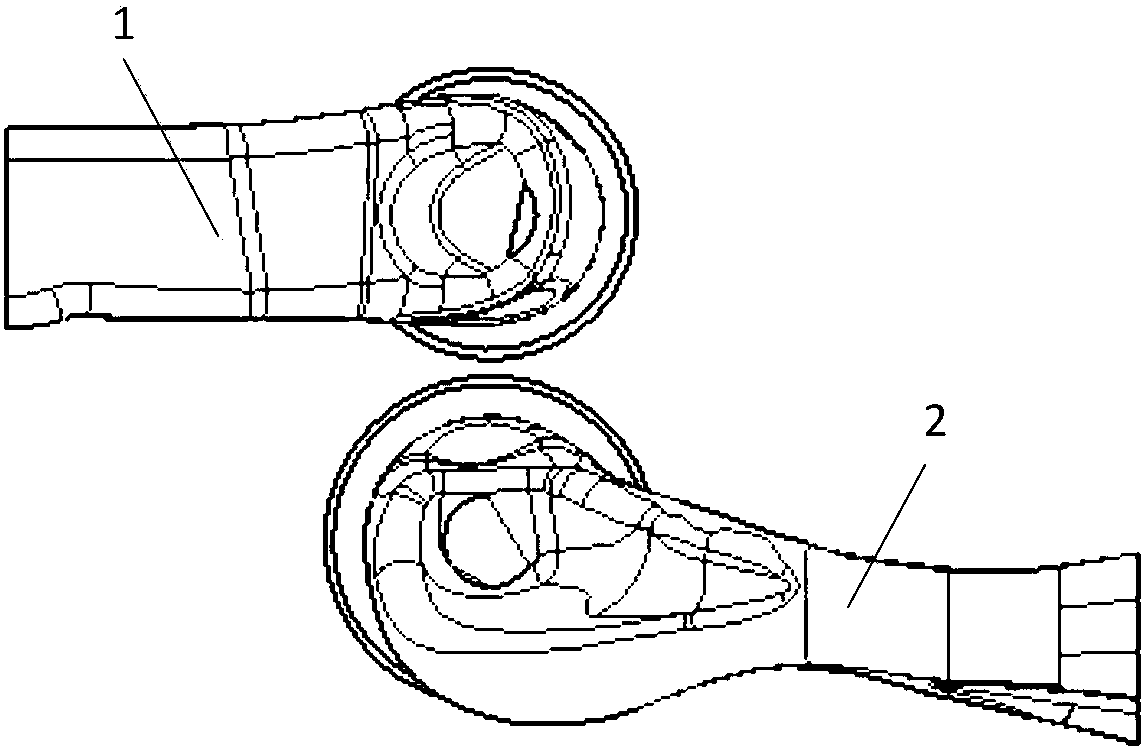

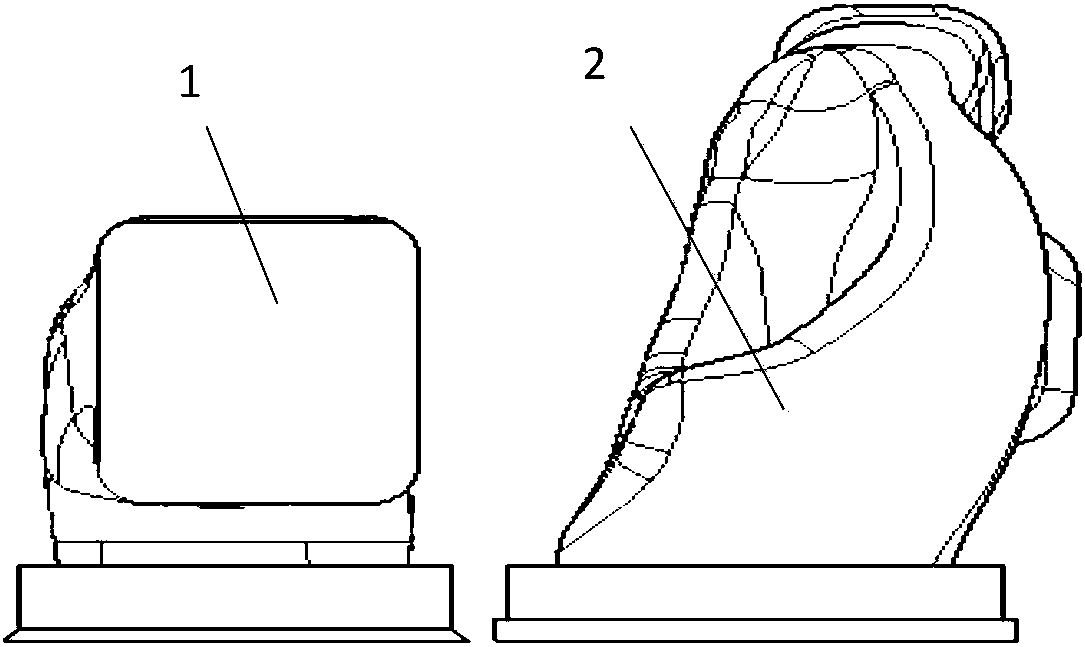

[0029] Such as Figure 1-Figure 8 As shown, an engine cylinder head air passage includes an intake passage 1 and an exhaust passage 2, and the inlet of the intake passage 1 is rectangular in shape;

[0030] The shape of the outlet of the exhaust duct 2 is gourd-like, including an upper gourd, a lower gourd and a contraction section connecting the upper gourd and the lower gourd. Both the upper gourd and the lower gourd are rectangular, and the area ratio is 1: 3;

[0031] The radius of curvature of the central trajectory line of the intake passage 1 increases sequentially from the entrance to the exit; the intake passage 1 is sequentially divided into a fuel injection area 1-1, a flow formation area 1-2 and a swirl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com