small turbofan engine

A turbofan engine, small-scale technology, applied in the direction of engine components, machine/engine, turbine/propulsion device air intake, etc., can solve the problem of difficult to increase compressor pressure, can not get significant effect, reduce engine volume, etc. problems, to achieve the effect of wide application range, reasonable design, and improved bypass ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

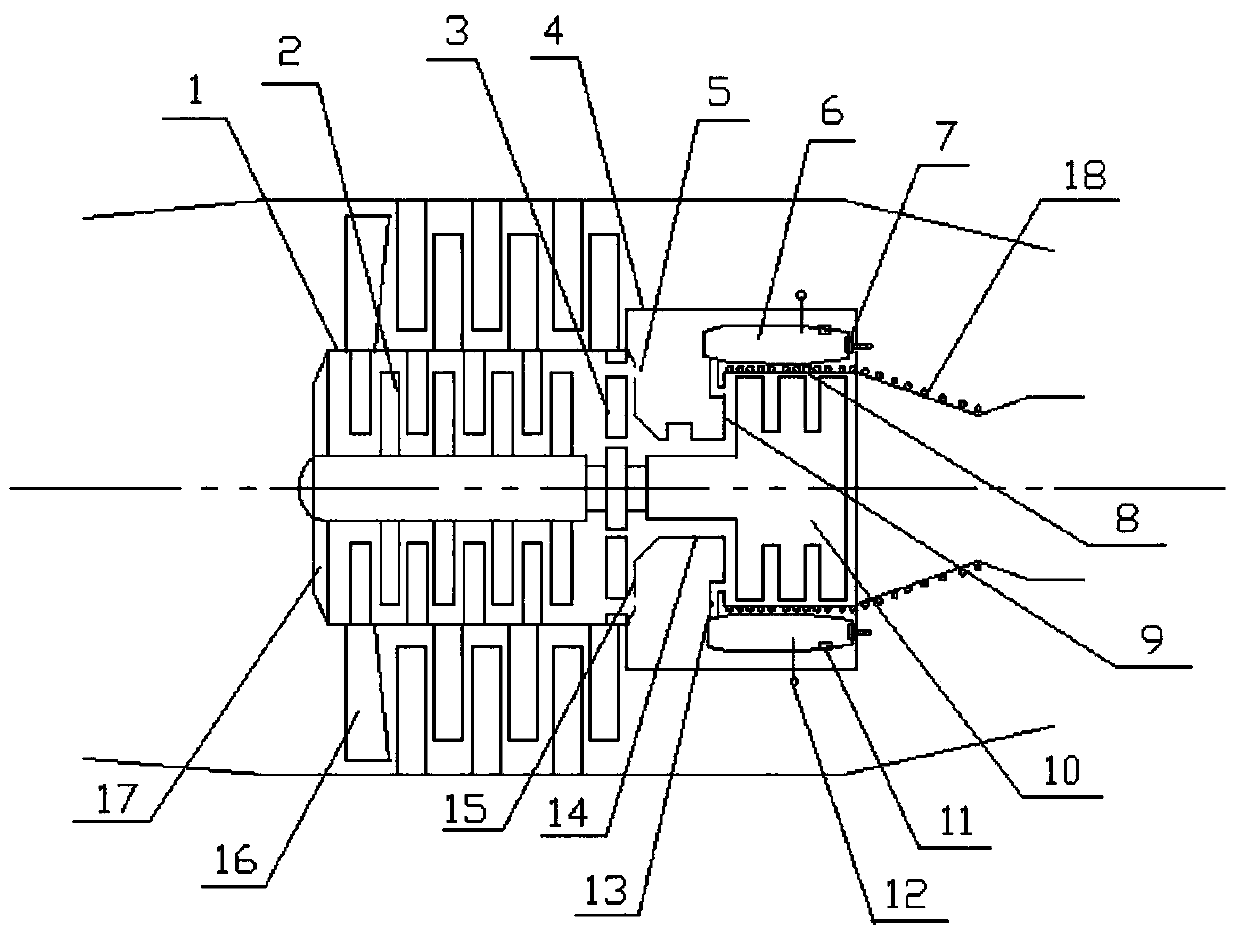

[0017] refer to figure 1 , a small turbofan engine, including a compressor, a combustion chamber 4 and a power turbine arranged in sequence along the intake direction, the compressor includes a compressor housing 1 and a centrifugal impeller 2, and the power turbine includes a turbine body 10 and a turbine The casing 8 and the combustion chamber 4 are provided with a connecting body 14 connecting the compressed gas casing 1 and the turbine casing 8. The connecting body 14 is provided with a compressed gas end cover 15 connected with the compressed gas casing 1 and connected with the turbine casing 8. The turbine end cover 9, the compressor end cover 15 is provided with a communication hole 5 communicating with the compressor ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com