A temperature self-maintaining carbon dioxide and water vapor co-electrolysis device and its application method

A carbon dioxide and electrolysis device technology, applied in the field of electrochemistry, can solve problems such as difficulty in large-scale integration into the power grid, difficulty in ensuring stable and continuous power supply, etc., and achieve the effects of avoiding temperature mismatch, compact layout, and efficient thermal coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

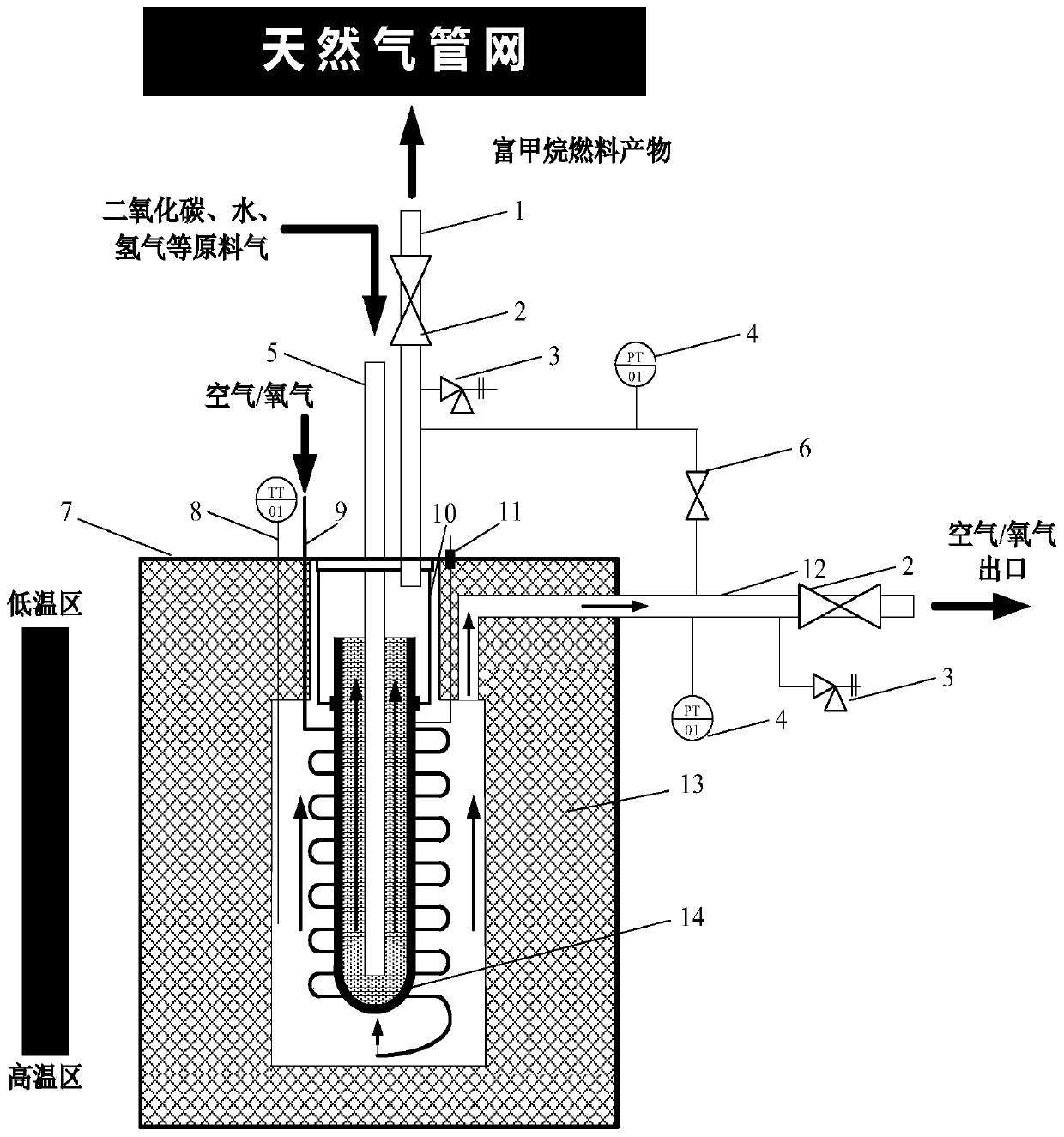

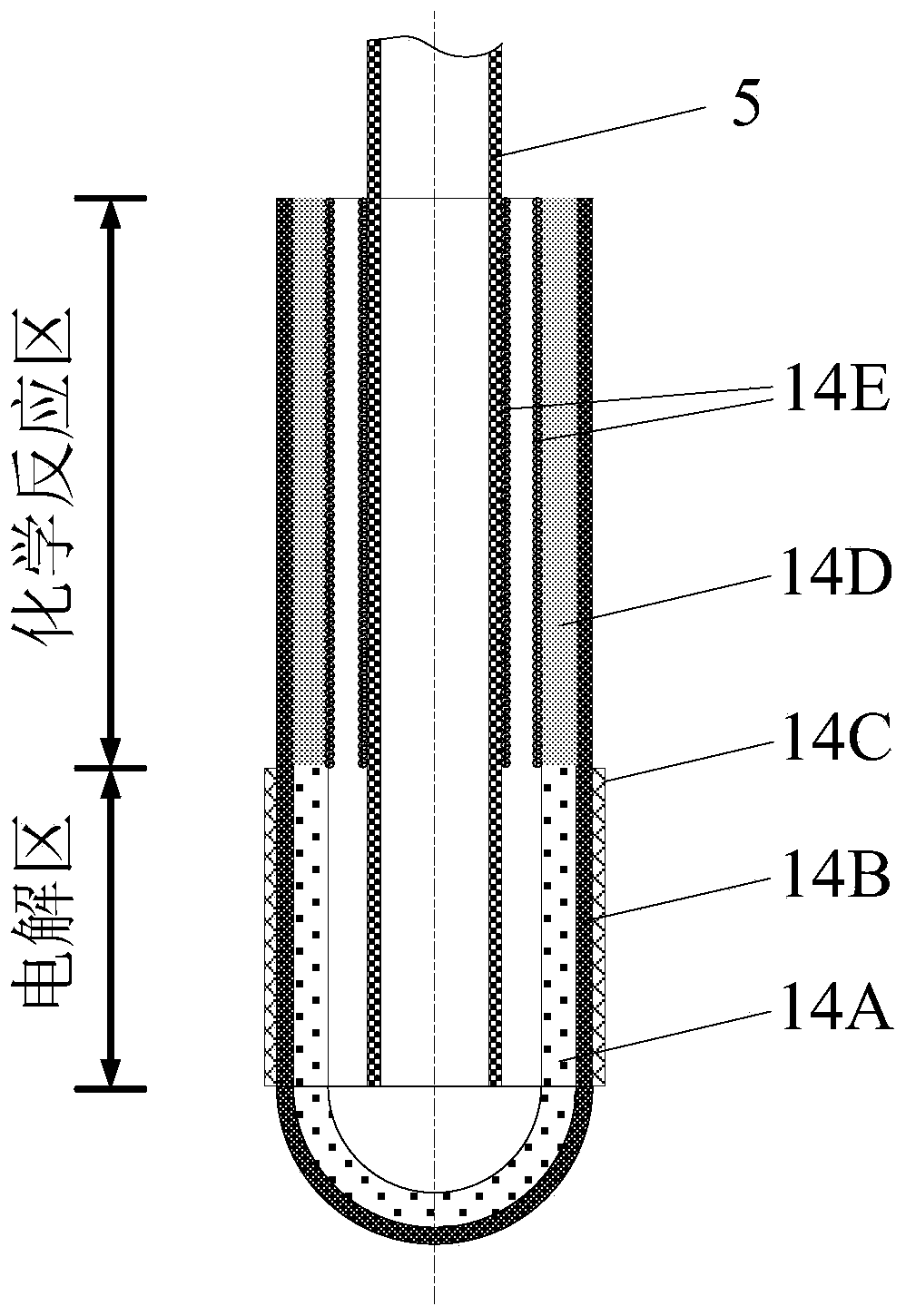

[0052] This embodiment is a temperature self-sustaining co-electrolysis device for carbon dioxide and water vapor applied to one-step synthesis of methane or Fischer-Tropsch fuel. Such as figure 1 As shown, the fuel electrode chamber casing 10 is sealed and connected with the tubular solid oxide electrolytic cell 14, and the entire reactor 7 is divided into a fuel electrode chamber (inside) and an air electrode chamber (outside). In the reaction kettle 7, an annular insulating material 13 is arranged around the fuel electrode chamber housing 10 and the tubular solid oxide electrolytic cell 14. Two holes are drilled on the upper part of the insulating material 13, one of which is used for the tubular solid oxide electrolytic cell. The air electrode collector wire 11 outside the electrolytic cell 14 is drawn out, and the other hole is to provide an air electrode flow channel, so that the air electrode gas can flow out from the air electrode chamber outlet pipe 12 on the upper si...

Embodiment 2

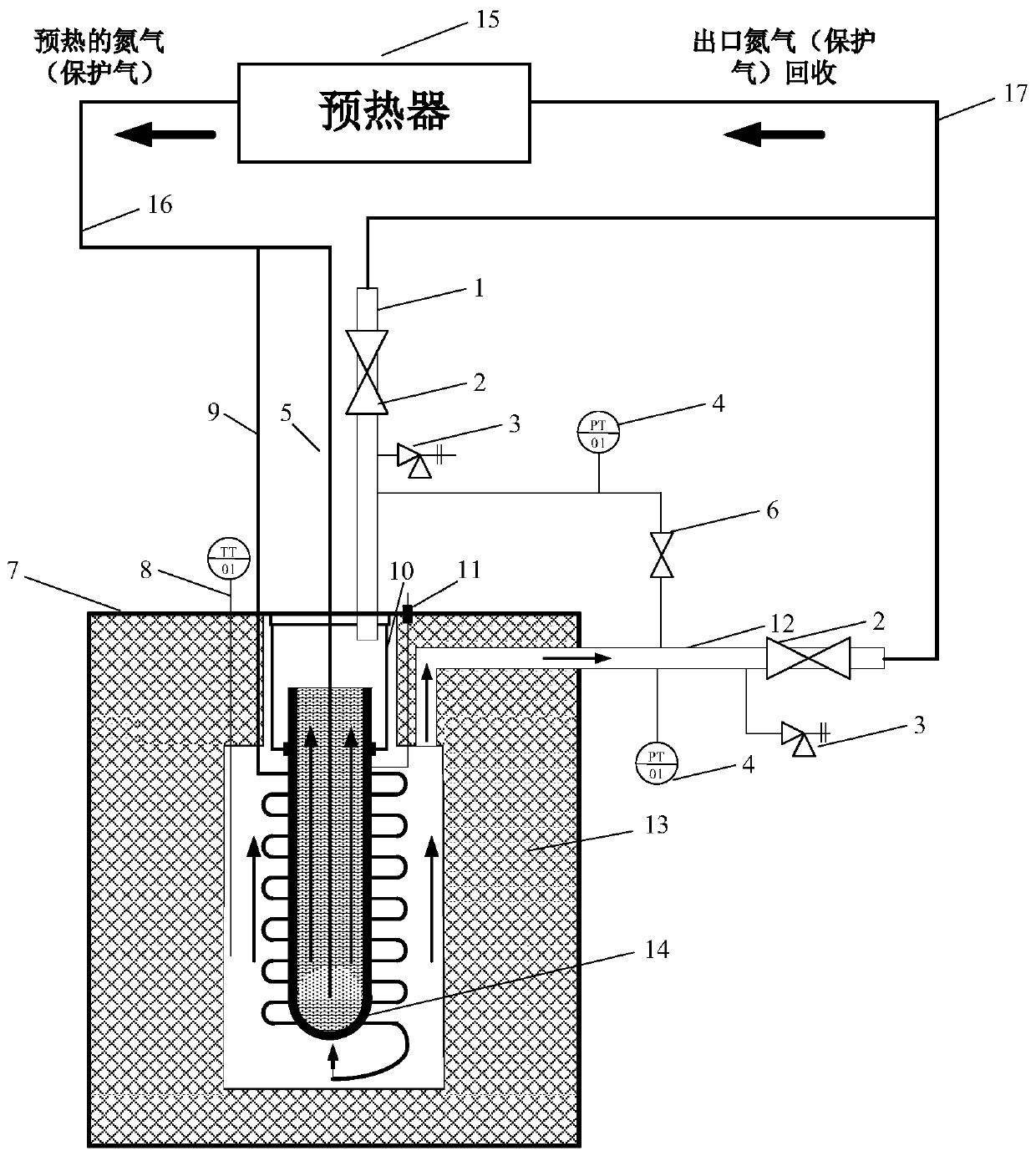

[0056] This embodiment is a start-up method for a temperature self-sustaining carbon dioxide and water vapor co-electrolysis device applied to one-step synthesis of methane or Fischer-Tropsch fuel. Such as image 3 As shown, it is in figure 1 On the basis of the above, a preheater 15, a preheater outlet pipe 16 and an inlet pipe 17 are added. The difference between this embodiment and Embodiment 1 is that the tubular solid oxide electrolytic cell 14 is in an open circuit state, and both the air electrode and the fuel electrode are fed with protective gas nitrogen. Open the communication valve 6, nitrogen passes into the fuel electrode and the air electrode chamber in the reactor 7 from the fuel electrode chamber inlet pipe 5 and the air electrode chamber inlet pipe 9, and passes through the fuel electrode chamber outlet pipe 1 and the air electrode chamber The outlet pipe 12 flows out, and after being recovered and reheated by the preheater, it is passed into the reactor 7 f...

Embodiment 3

[0059] This embodiment is a device for one-step synthesis of methane or Fischer-Tropsch fuel with self-maintaining carbon dioxide and water vapor co-electrolysis tube stack. Such as image 3 shown. The difference between this embodiment and embodiment 1 is that the tubular solid oxide electrolytic cell unit in embodiment 1 is expanded into a tubular solid oxide electrolytic cell stack, and each tubular solid oxide electrolytic cell unit is connected in parallel The air electrode is connected by the air electrode collector wire 11, and the fuel electrode is connected by the collector connection of the fuel electrode chamber inlet pipe 5.

[0060] The advantage of this embodiment is that the stack of tubular solid oxide electrolytic cells is used to realize the parallel connection of multiple tubes, which improves the synthetic fuel yield of the device, and the use of tubular solid oxide electrolytic cells is easier to stack and scale up, and has a compact structure arrangemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com