Upgrading and denitriding modification method by using high-nitrogen biomass wastes as fuel

A biomass waste and fuel technology, which is applied in the fields of biofuels, waste fuels, and fuels, can solve the problems of large limitations in thermal drying and dehydration, low mechanical dehydration efficiency, and high energy consumption for thermal drying and dehydration, and achieve efficient and clean heat. Chemical utilization, low nitrogen content, high energy density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

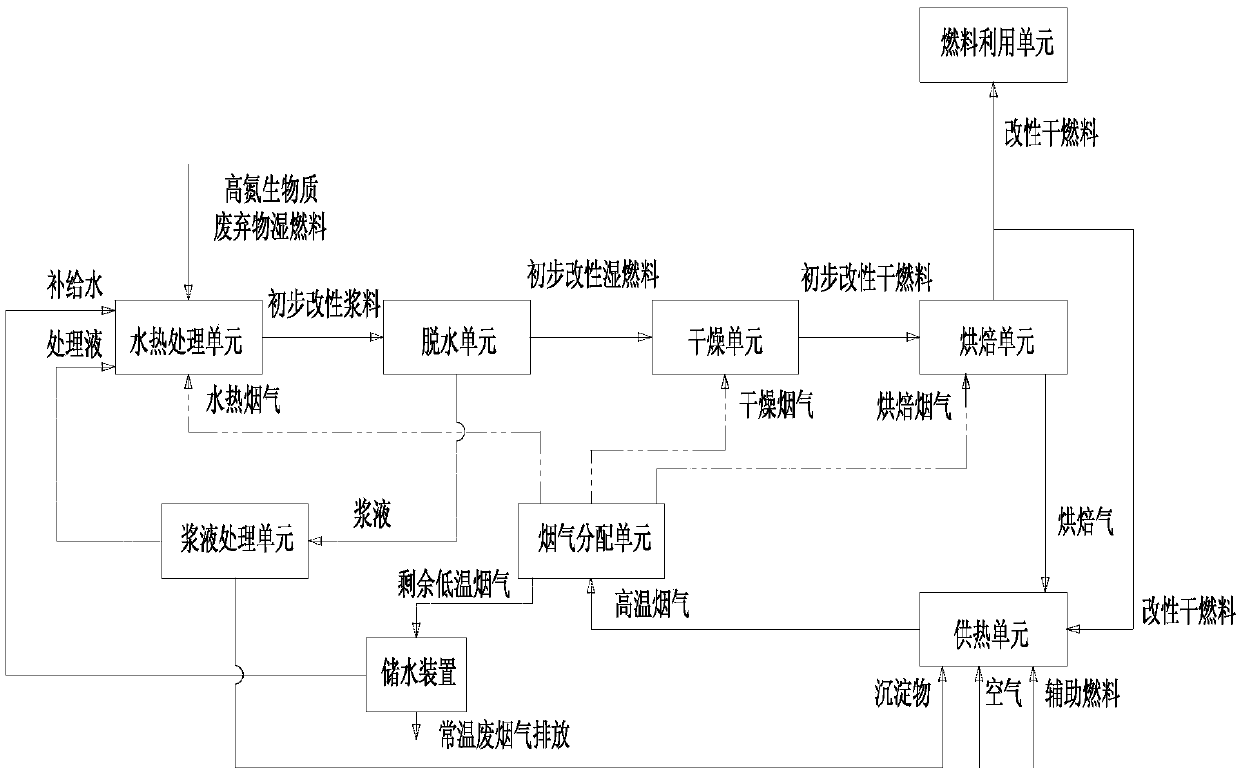

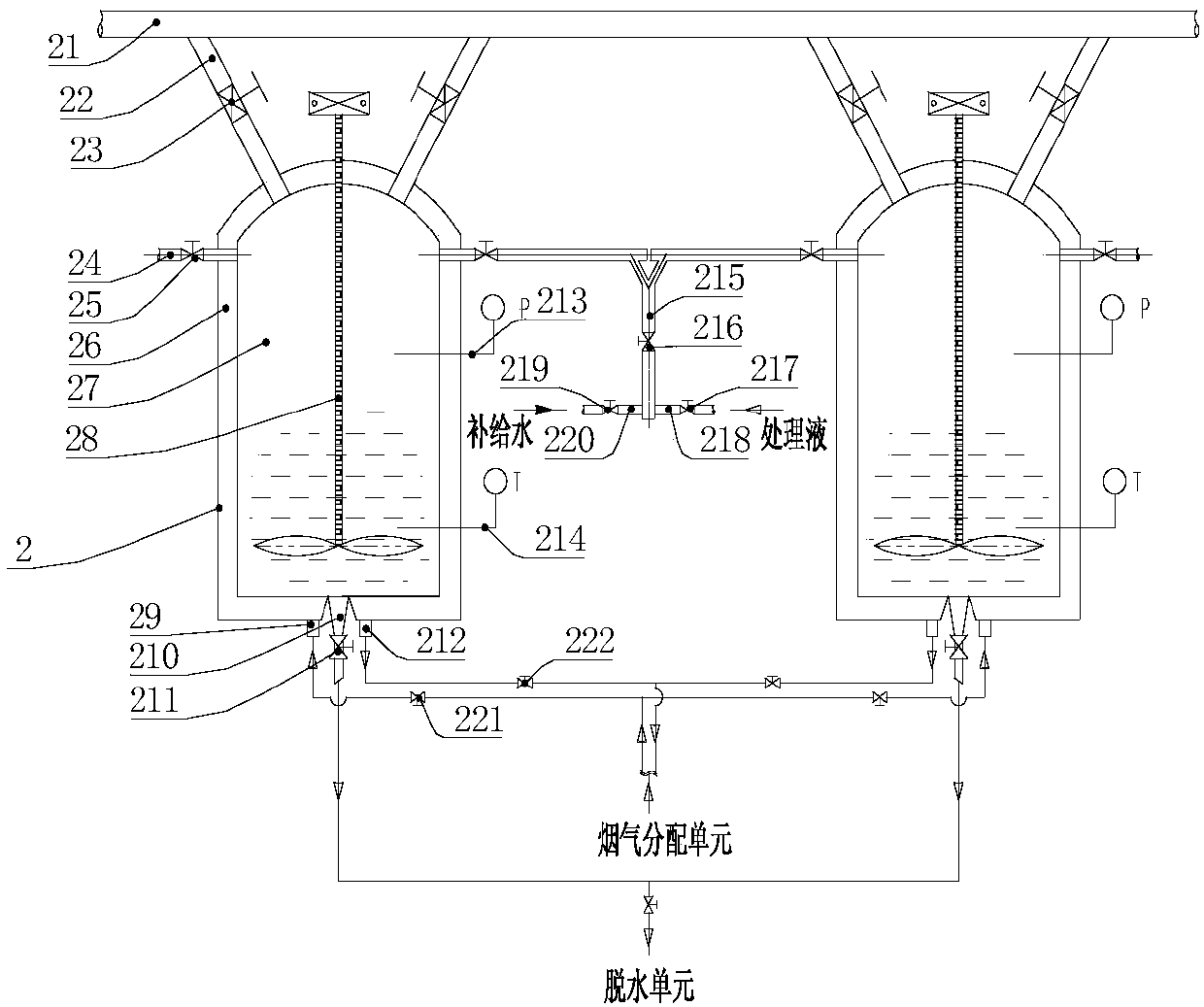

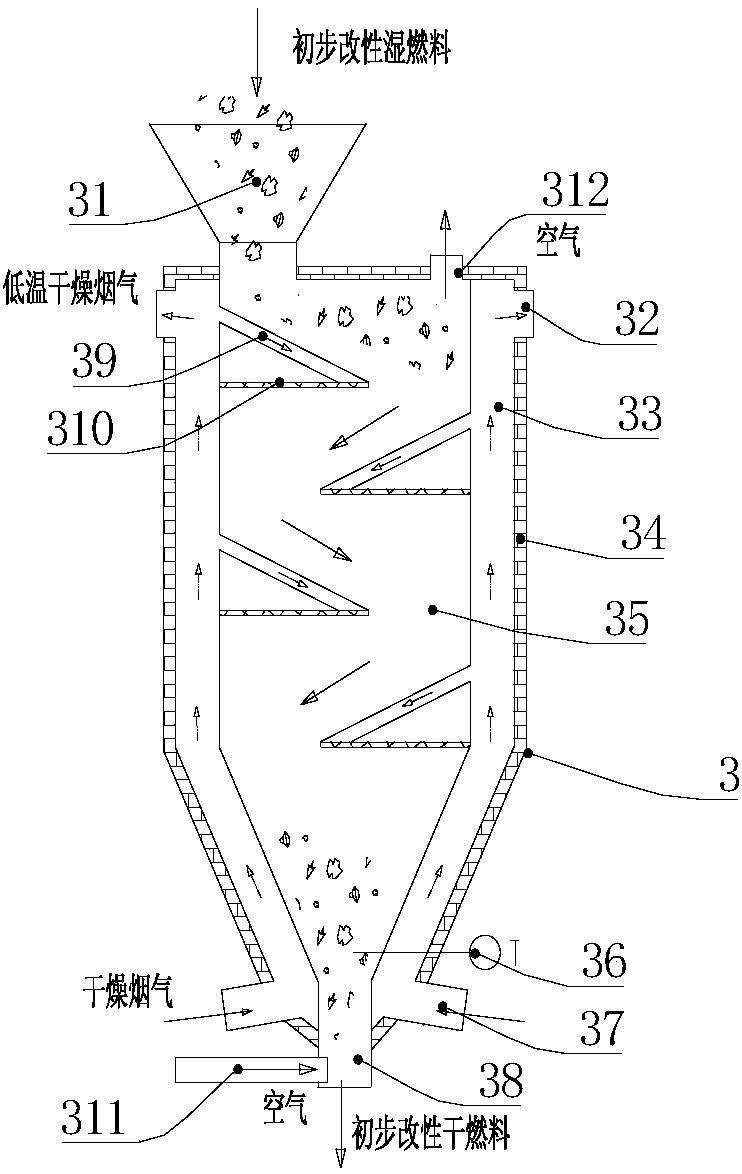

[0040] Such as Figure 1-7 As shown, the upgrading and denitrification modification method of using high-nitrogen biomass waste as fuel includes a hydrothermal treatment unit, a dehydration unit, a drying unit, and a torrefaction unit for modifying high-nitrogen biomass waste in sequence, as well as providing energy The heat supply unit, the flue gas distribution unit and the slurry treatment unit and the water storage device of the balance material, the method includes the following steps:

[0041] (1) Under the thermal action of hydrothermal flue gas, the high-nitrogen biomass waste and softened water from the water storage device enter the hydrothermal treatment unit for mixing, and then perform hydrothermal preliminary upgrading and denitrification treatment to obtain preliminary modified slurry. The temperature of the hydrothermal treatment unit is controlled at 180°C to 210°C, and the hydrothermal treatment time is 10 minutes;

[0042] (2) The preliminary modified slurr...

Embodiment 2

[0057] Such as Figure 1-7 As shown, it is the same as Example 1, except that the high-nitrogen biomass waste is a mixture of antibiotic slag and peat, wherein the mass ratio of antibiotic slag and peat is 1:1.

[0058] In this embodiment, the mass ratio of demineralized water to high-nitrogen biomass waste is 0.08, and the hydrothermal treatment time is 60 minutes. The nitrogen of the preliminary modified slurry fuel obtained by the hydrothermal treatment unit is reduced by 46% to 55%, and the unit dry basis heat The value can be increased by 4% to 7%. The mass ratio of the modified dry fuel delivered to the fuel utilization unit and the heating unit is 10:1. The dehydration unit adopts mechanical filter press method for dehydration, the pressure is 6MPa, and the dehydration treatment time is 25min. rate dropped to 55% to 60%.

[0059] The drying unit adopts a horizontal drying box, such as Figure 4 As shown, the fuel channel is connected with auxiliary air that is opposi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com