Oil-water separation pry for oily sludge treatment

A technology of oil-water separation and sludge sludge, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problem of oil resources not being recycled, secondary pollution, oil recovery Low efficiency and other problems, to achieve the effect of efficient resource utilization, easy recycling and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

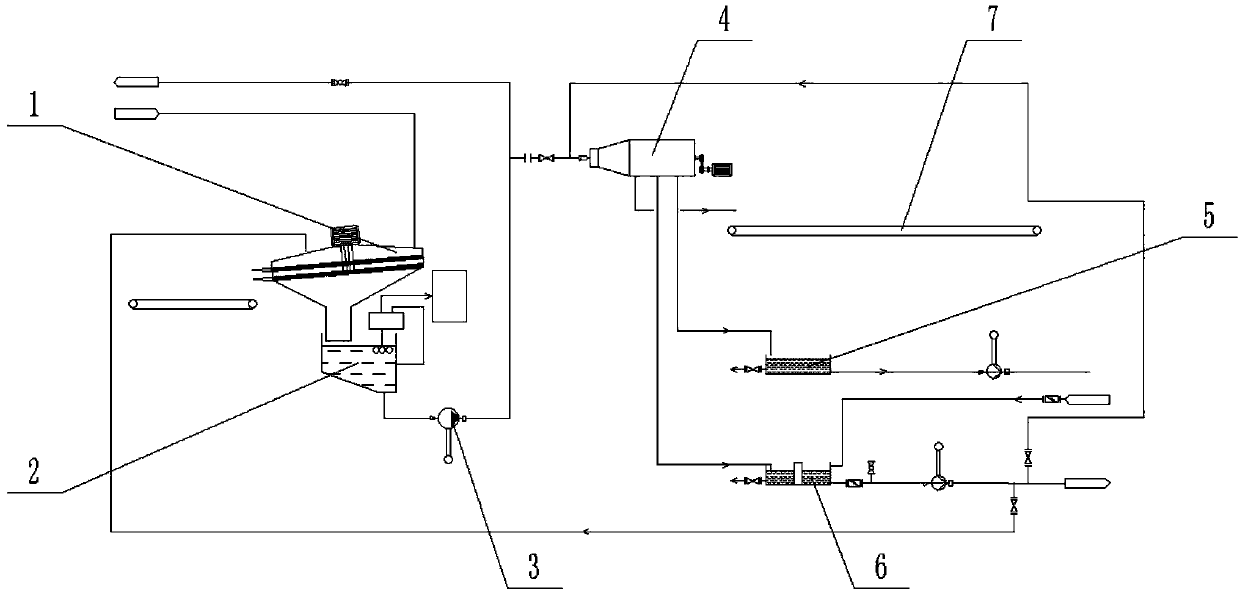

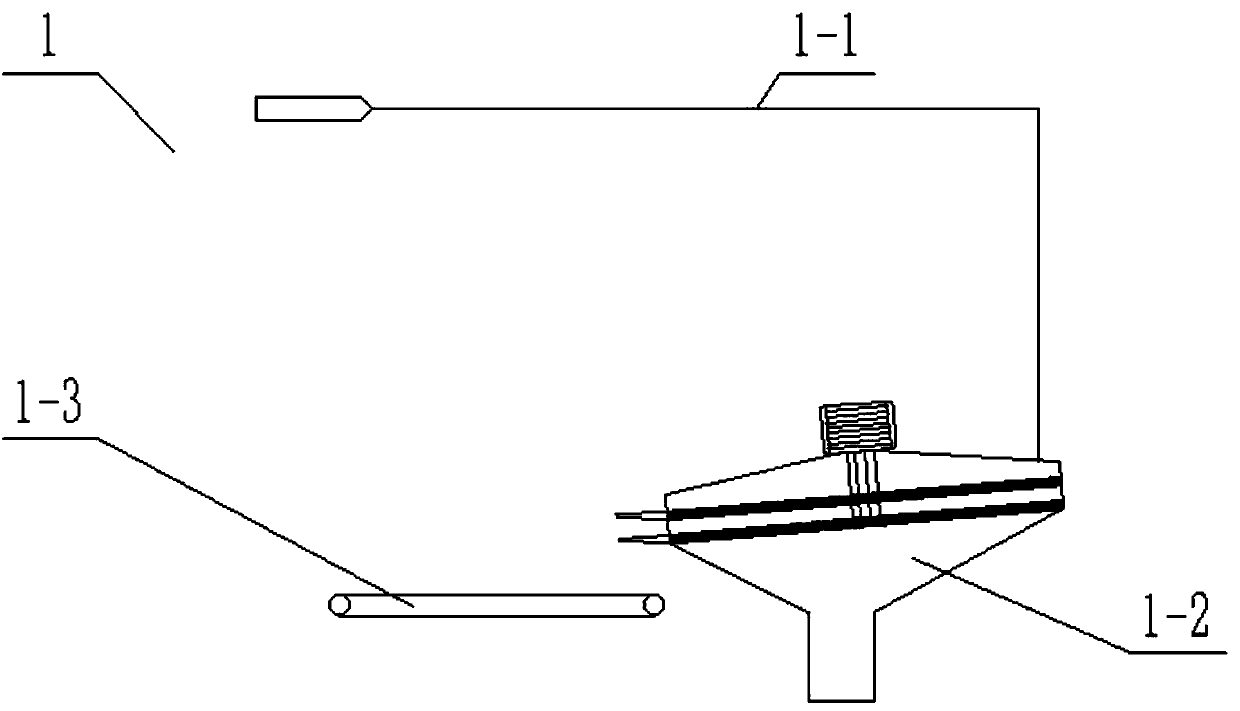

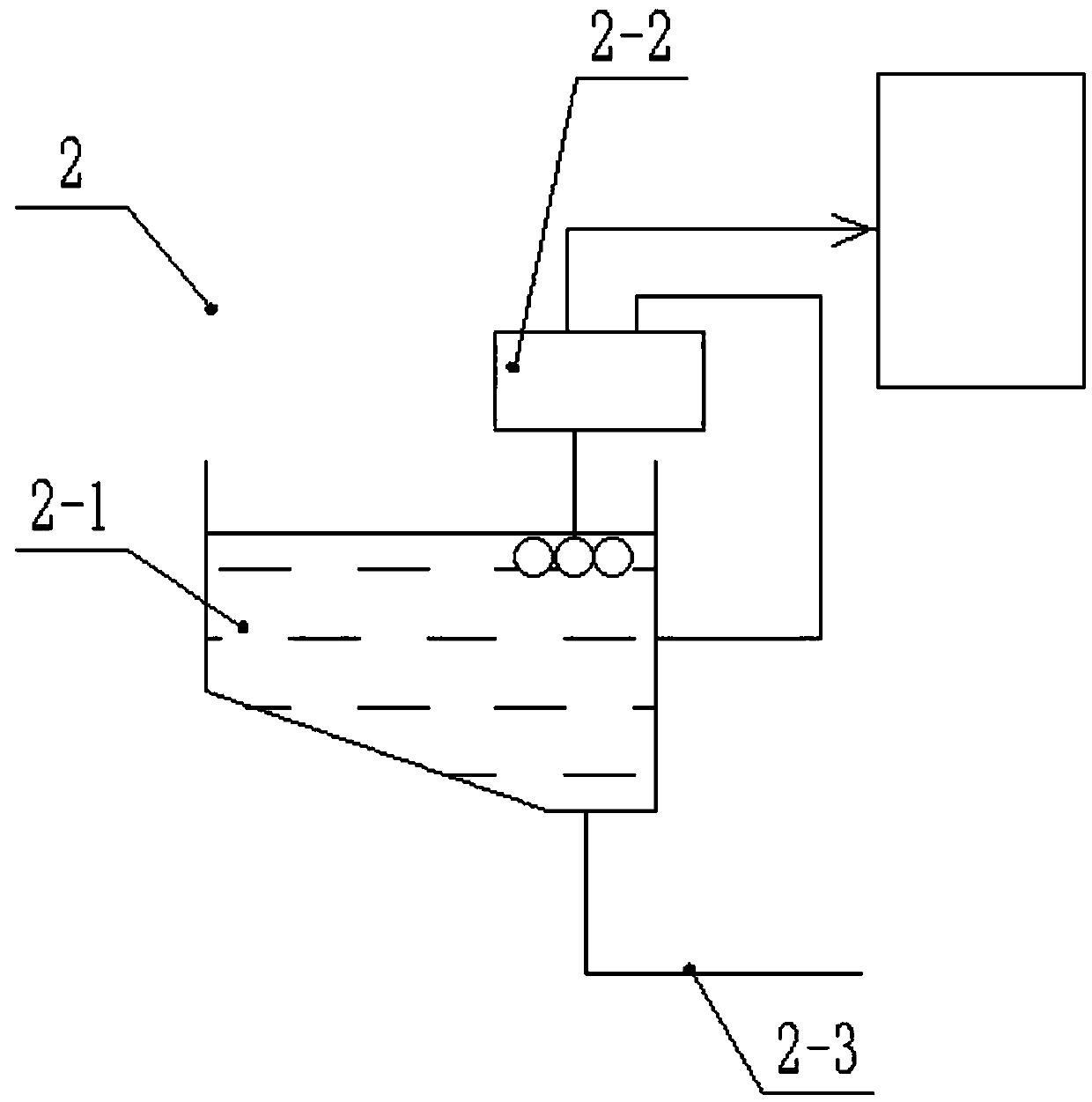

[0037] Such as Figure 1-7 As shown, an oil-water separation skid for sewage sludge treatment includes a slurry material screening device 1, an oil liquid pre-collection device 2, a screening material delivery pipe assembly 3, a three-phase separation device 4, an oil liquid storage device 5, a circulation The water pipe assembly 6 and the standard sediment conveyor 7, the slurry material screening device 1 is arranged on the upper end of the oil liquid pre-collection device 2; the lower end of the oil liquid pre-collection device 2 is connected through the screening material conveying pipe assembly 3 Three-phase separation device 4; the lower end of the three-phase separation device 4 is provided with an oil storage device 5, a circulating water pipe assembly 6 and a standard sediment conveyor 7; the circulating water pipe assembly 6 is connected to the slurry screening device 1 and the screen Distribution pipe assembly 3.

[0038] The slurry screening device 1 includes a slur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com