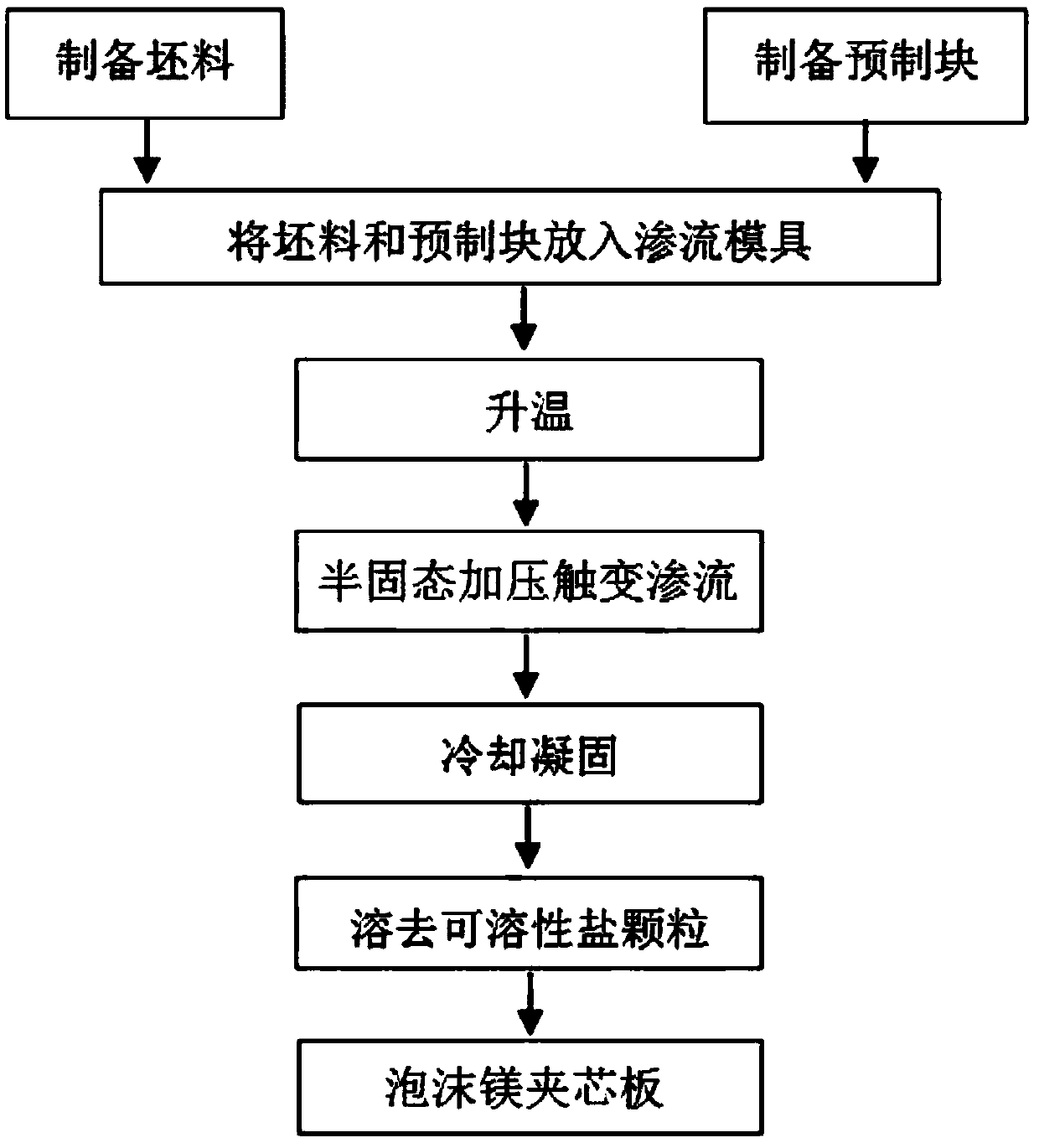

A kind of foam magnesium sandwich panel and semi-solid thixotropic seepage casting method

A technology of sandwich panels and foamed magnesium, which is applied in the field of preparation of porous metal materials, can solve problems such as high chemical activity and difficulties, and achieve the goals of improving mechanical properties, improving safety, high compressive/tensile strength and bonding strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1, a semi-solid thixotropic seepage casting method for a magnesium foam sandwich panel, which comprises the following steps:

[0034] 1) Preparing the billet, machining the non-dendritic AZ91 magnesium alloy ingot into two billets, the billet is a cylinder with a diameter of 50 mm and a height of 15 mm; the weight ratio of the components of the AZ91 magnesium alloy is: Al: 8.3 ~9.7%, Zn: 0.35~1.0%, Mn: 0.15~0.5%, Si:<0.01%, Cu:<0.03%, Ni:<0.002%; Fe:<0.005%, the rest is Mg;

[0035] 2) Prepare prefabricated blocks, pre-dehydrate NaCl particles with a particle size of 5-12 meshes, and then place the treated NaCl particles in a prefabricated block mold to make a prefabricated block. The prefabricated block is 50 mm in diameter, A cylinder with a height of 10mm;

[0036] 3) Prepare the non-dendritic magnesium alloy semi-solid slurry, put the billet and the prefabricated block into the percolation mold, separate the two billets with the prefabricated block, then...

Embodiment 2

[0039] Embodiment 2, a semi-solid thixotropic seepage casting method for a magnesium foam sandwich panel, which comprises the following steps:

[0040] 1) Preparing billets, mechanically processing semi-non-dendritic AZ61 magnesium alloy ingots into two billets, the billets are cylinders with a diameter of 50 mm and a height of 15 mm; wherein the weight ratio of the components of the AZ61 magnesium alloy is: Al: 5.6~6.5%, Zn: 0.35~1.0%, Mn: 0.15~0.5%, Si:<0.01%, Cu:<0.03%, Ni:<0.002%, Fe:<0.005%, and the rest is Mg;

[0041] 2) Prepare prefabricated blocks, pre-dehydrate NaCl particles with a particle size of 5-12 meshes, and then place the treated NaCl particles in a prefabricated block mold to make a prefabricated block. The prefabricated block is 50 mm in diameter, A cylinder with a height of 10mm;

[0042] 3) Prepare the non-dendritic magnesium alloy semi-solid slurry, put the billet and the prefabricated block into the percolation mold, separate the two billets with the ...

Embodiment 3

[0045] Embodiment three, a semi-solid thixotropic seepage casting method for a magnesium foam sandwich panel, which comprises the following steps:

[0046] 1) Preparing blanks, machining non-dendritic ZA84 magnesium alloy ingots into two blanks, the blanks are cylinders with a diameter of 50 mm and a height of 15 mm; the weight ratio of the components of the AZ84 magnesium alloy is: Zn: 7.4 ~8.2%, Al: 3.6~4.5%, Mn: 0.15~0.40%, Si: <0.01%, Cu: <0.03%, Ni: <0.002%, Fe: <0.005%, and the rest is Mg.

[0047] 2) Prepare prefabricated blocks, pre-dehydrate NaCl particles with a particle size of 5-12 meshes, and then place the treated NaCl particles in a prefabricated block mold to make a prefabricated block. The prefabricated block is 50 mm in diameter, A cylinder with a height of 10mm;

[0048] 3) Prepare the non-dendritic magnesium alloy semi-solid slurry, put the billet and the prefabricated block into the percolation mold, separate the two billets with the prefabricated block, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com