Etchant for copper/molybdenum-based multilayer thin film

A technology of multilayer film and etching solution, which is applied in the field of etching solution for multilayer film, can solve problems such as changes in etching rate, and achieve the effect of reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

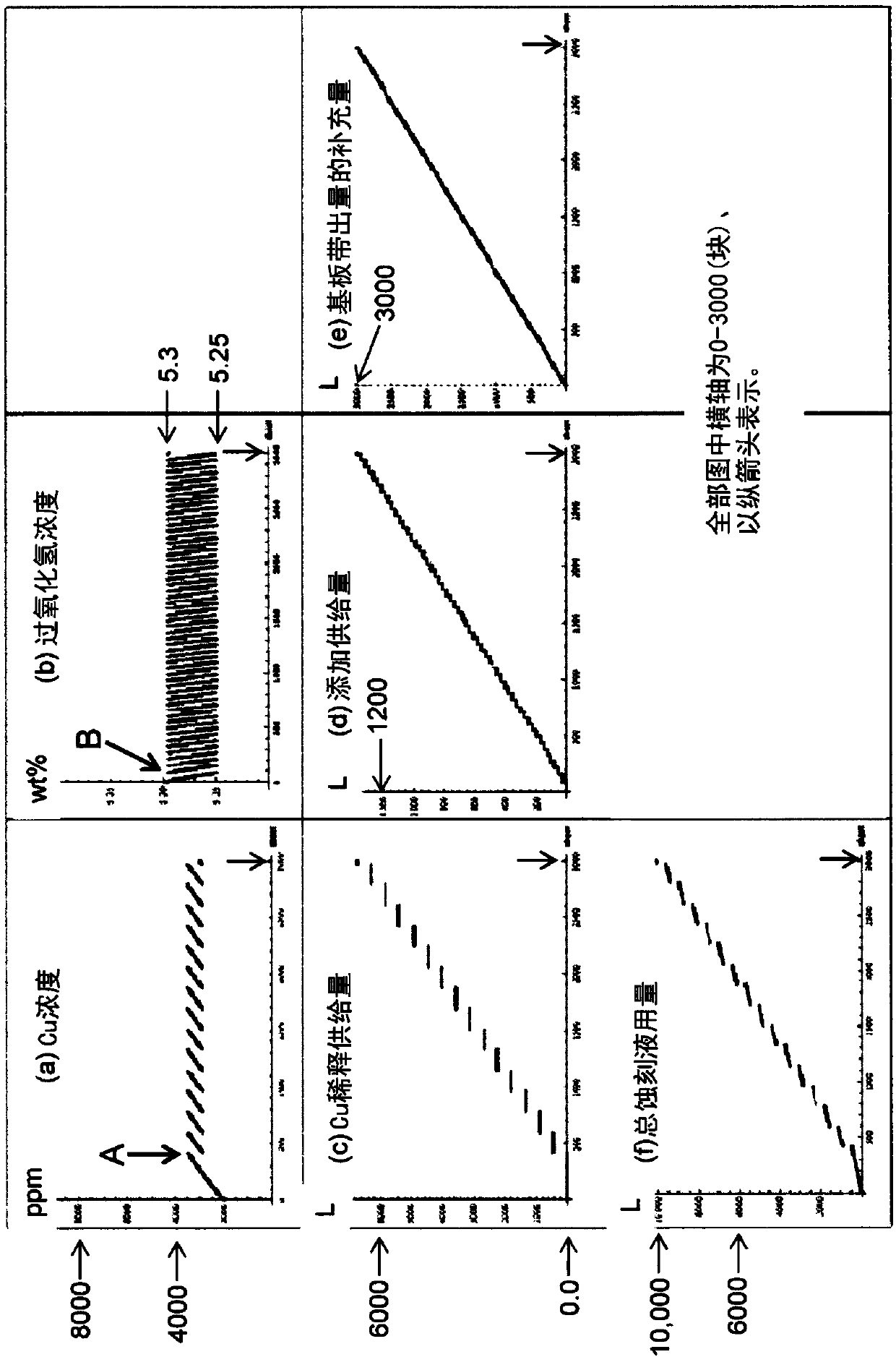

Embodiment 1

[0147] 1.90% by mass of glycolic acid as an acidic organic acid, 3.40% by mass of malonic acid, 0.80% by mass of lactic acid, 2.20% by mass of 1-amino-2-propanol as an amine compound, and 0.90% by mass of BG as a hydrogen peroxide stabilizer. % by mass, 0.08% by mass of 5-amino-1H-tetrazole as an azole, 0.26% by mass of aluminum lactate as a precipitation preventing agent, and 75.32% by mass of water were prepared as etching solution raw materials to prepare an etching concentrate. In addition, the ratio of each component in an etching concentrate liquid is shown by the ratio with respect to the total amount at the time of mixing with the hydrogen peroxide solution mentioned later and completing an etching liquid. The same applies to the following examples and comparative examples.

[0148] 15.14% by mass of a 35% hydrogen peroxide solution (5.3% by mass of hydrogen peroxide and 9.84% by mass of water relative to the total amount of the etching solution) was mixed with the etc...

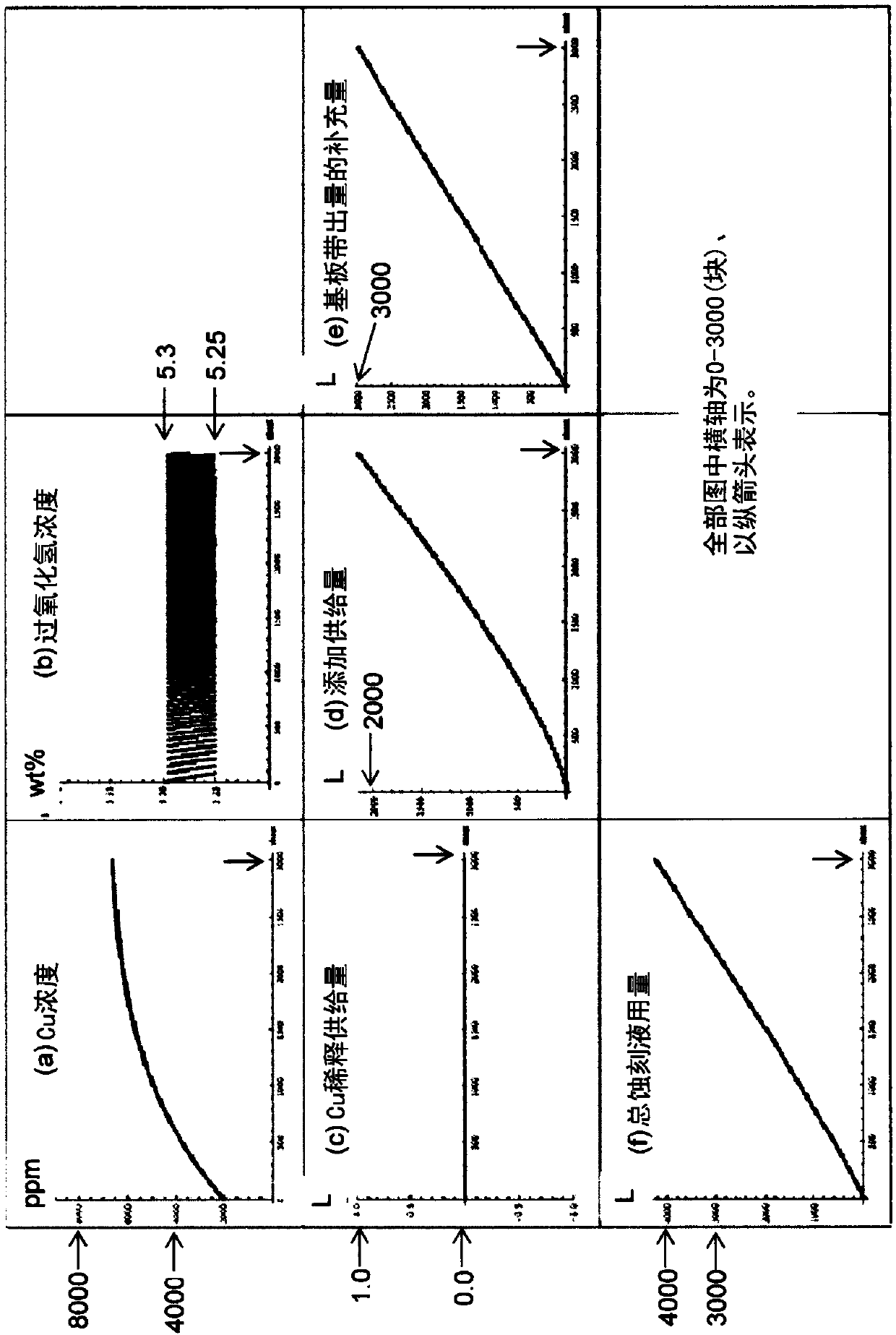

Embodiment 2

[0150] 1.90% by mass of glycolic acid as an acidic organic acid, 3.40% by mass of malonic acid, 0.80% by mass of lactic acid, 2.20% by mass of 1-amino-2-propanol as an amine compound, and 2.00% of BG as a hydrogen peroxide stabilizer % by mass, 0.08% by mass of 5-amino-1H-tetrazole as an azole, 0.26% by mass of aluminum lactate as a precipitation preventing agent, and 74.22% by mass of water were prepared as etching solution raw materials to prepare an etching concentrate.

[0151] 15.14% by mass of a 35% hydrogen peroxide solution (5.3% by mass of hydrogen peroxide and 9.84% by mass of water relative to the total amount of the etching solution) was mixed with the etching concentrate to prepare an etching solution having a hydrogen peroxide concentration of 5.3% by mass. In addition, water was 84.06 mass % in total. Further, copper lactate was added to adjust the copper ion concentration to 8000 ppm. In addition, molybdenum powder was added to adjust the molybdenum concentrat...

Embodiment 3

[0153] Contains 1.90% by mass of glycolic acid as an acidic organic acid, 3.40% by mass of malonic acid, 0.80% by mass of lactic acid, 2.20% by mass of NNDPA as an amine compound, 0.40% by mass of BG as a hydrogen peroxide stabilizer, and 0.40% by mass of BG as a hydrogen peroxide stabilizer. 0.08% by mass of 5-amino-1H-tetrazole, 0.26% by mass of aluminum lactate as a precipitation preventing agent, and 75.82% by mass of water were prepared as etching solution raw materials to prepare an etching concentrate.

[0154] 15.14% by mass of a 35% hydrogen peroxide solution (5.3% by mass of hydrogen peroxide and 9.84% by mass of water relative to the total amount of the etching solution) was mixed with the etching concentrate to prepare an etching solution having a hydrogen peroxide concentration of 5.3% by mass. In addition, water was 85.66 mass % in total. Further, copper lactate was added to adjust the copper ion concentration to 8000 ppm. In addition, molybdenum powder was adde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com