Fiber reinforced thermoplastic plastic composite tube failure analysis method

A thermoplastic and fiber-reinforced technology, applied in the field of failure analysis of fiber-reinforced thermoplastic composite pipes, can solve problems such as unsystematic and blind failure analysis of non-metallic composite pipes, and achieve the effect of easy implementation, easy reference and use, and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

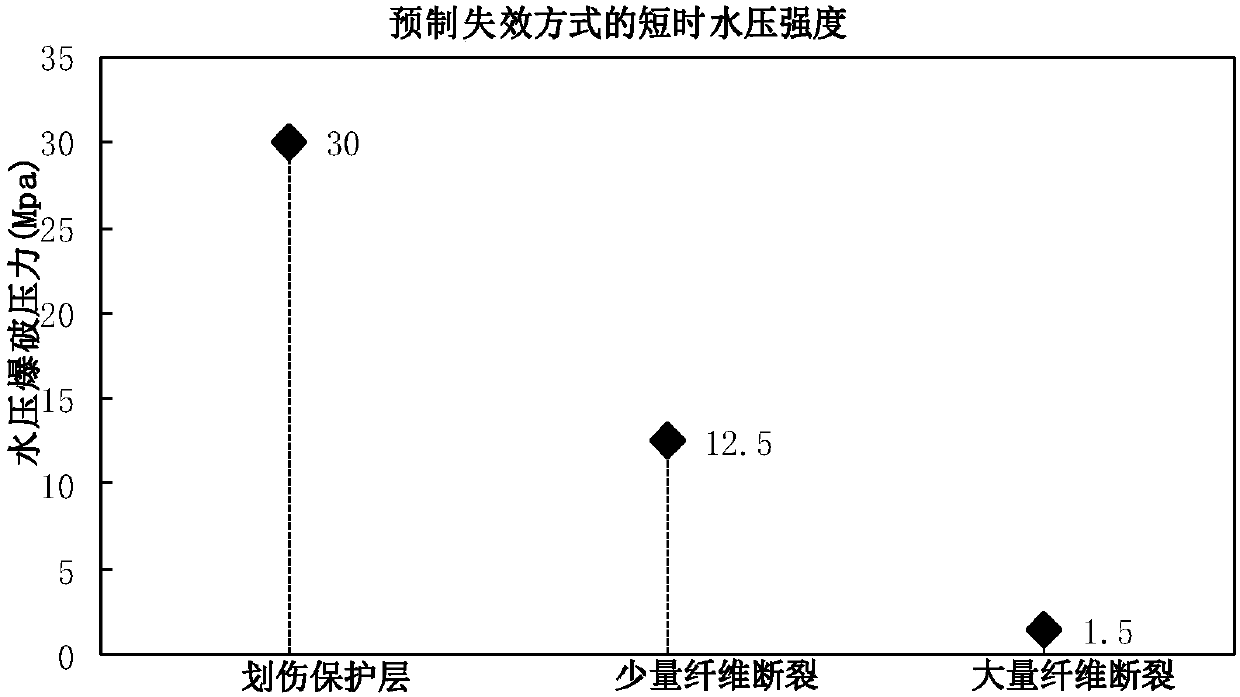

[0047] Example 1: Judging the cause of failure of polyester fiber reinforced polyethylene composite pipes in service in an oil field at room temperature

[0048] (1) Select the pipe material and preparation work required for the test. Randomly select 4 pipes from the same batch as the field service, and 1 pipe is a group, numbered 1#, 2#, 3#, 4# respectively. (2) Simulate the failure mode. Pipes 2#, 3#, and 4# were prefabricated in three failure modes: artificially scratched protective layer, a small amount of fiber fracture, and a large number of fiber fractures, respectively, using tools. (3) Short-term hydraulic failure test. According to the standard GB / T15560-1995, the blasting test was carried out on the prefabricated failure mode pipes 2#, 3#, 4# and the non-prefabricated failure mode pipe 1#, and the short-term hydraulic failure strength was tested to obtain the value, 1#, 2 #, 3#, 4# composite pipe short-term hydraulic pressure failure strength values were 30MPa,...

example 2

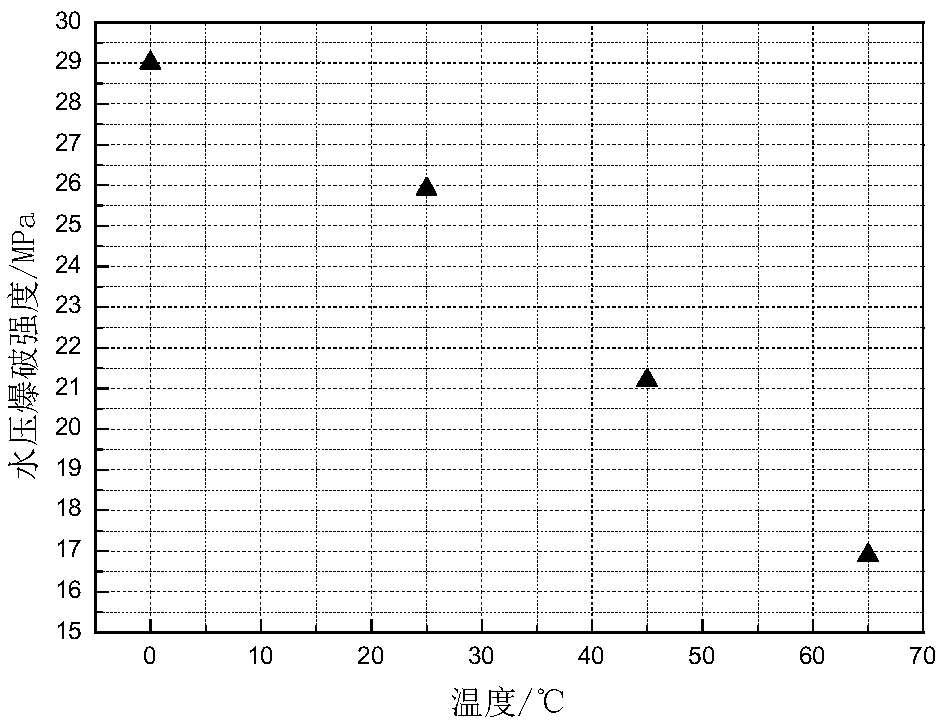

[0050] Example 2: Judging the cause of failure of polyester fiber reinforced polyethylene composite pipes in high temperature environment (45°C) in an oil field

[0051](1) Select the pipe material and preparation work required for the test. Randomly select 4 pipes from the same batch as the field service, and 1 pipe is a group, numbered 1#, 2#, 3#, 4# respectively. (2) Carry out the test of simulated temperature. Select 0°C, 25°C, 45°C and 65°C temperature points for insulation. The distribution of temperature points includes extreme temperature points of 0°C, 65°C and service temperature of 45°C. (3) Short-term hydraulic failure test. According to the standard GB / T15560-1995, the blasting test is carried out on the pipes 1#, 2#, 3# and 4# of the prefabricated failure mode, and the short-term hydraulic failure strength is tested, and the value is obtained. 1#, 2#, 3#, The short-term hydraulic failure strength values of 4# composite pipes are 29MPa, 26MPa, 21MPa and 17MP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com