A kind of n-octadecyl ethyl imidate methyl ester and its synthetic method

A technology of methyl octadecyl ethyl imide and a synthetic method, applied in directions such as organic chemistry, can solve the problems of complex reaction process, low yield of imidate, no published literature report on the production method, etc. The process method is simple, the yield is high, and the effect of filling the blank of production technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a kind of methyl N-octadecyl acetimidate, which is synthesized through the following steps:

[0037] Weigh 2.78g of octadecylamine into a four-neck flask with a condenser, vacuum device and thermometer, add 55mL of methanol, and heat until octadecylamine is completely dissolved in a constant temperature oil bath;

[0038] When the temperature rises to 70°C, slowly drop 1.72g of N,N-dimethylacetamide dimethyl acetal into the solution, and react at 0.1MPa for 2.8h;

[0039] TLC (V CHCl3:CH3OH =3:1) sample climbing board, no raw material point occurs, indicating that octadecylamine is fully converted;

[0040] Reduce the pressure to 0.07MPa, and continue the reaction at 50°C for 30 minutes to obtain a light yellow liquid product, namely methyl N-octadecylglycolimate, the yield of methyl N-octadecylglycolimate was 71.3%.

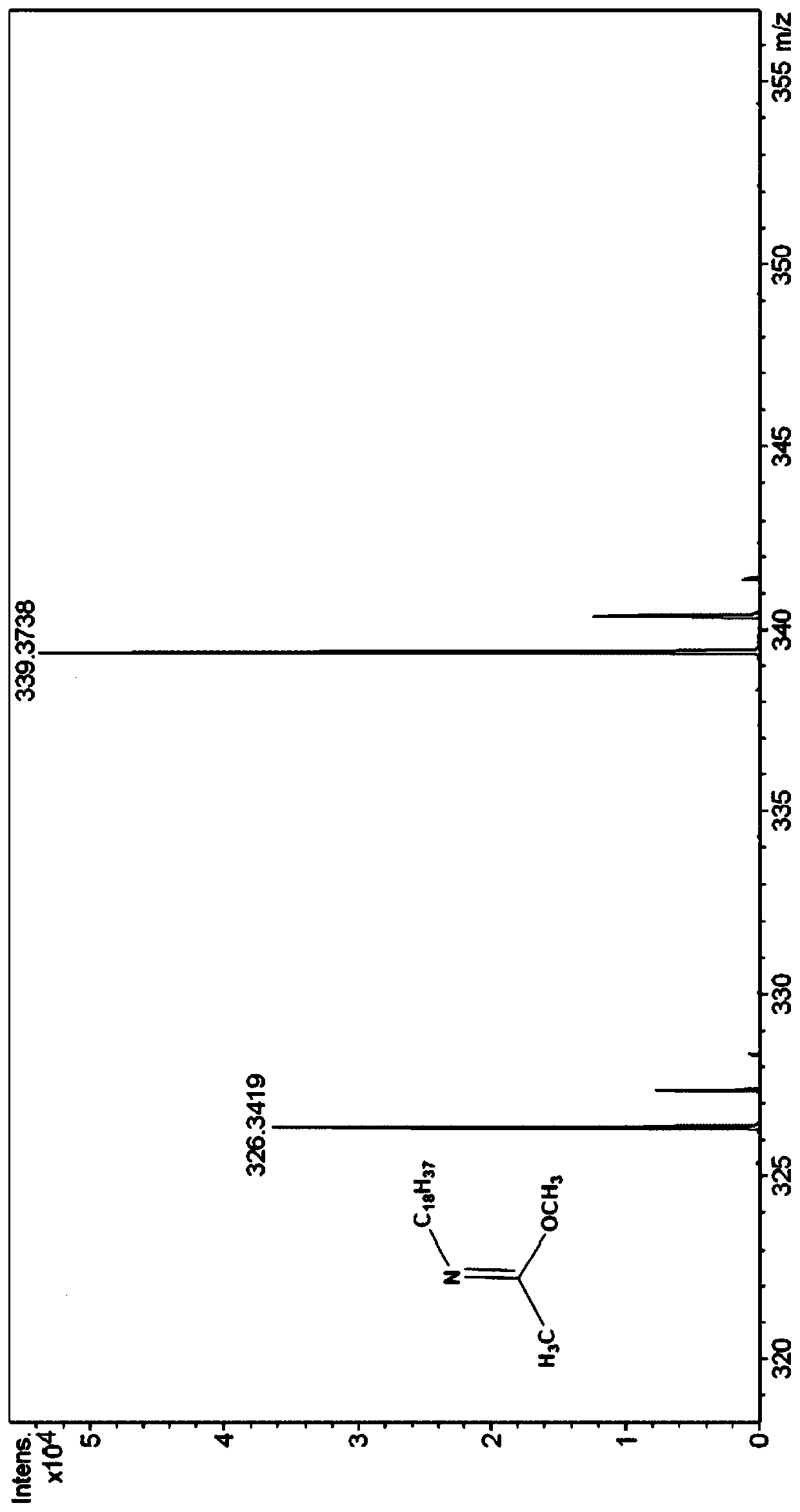

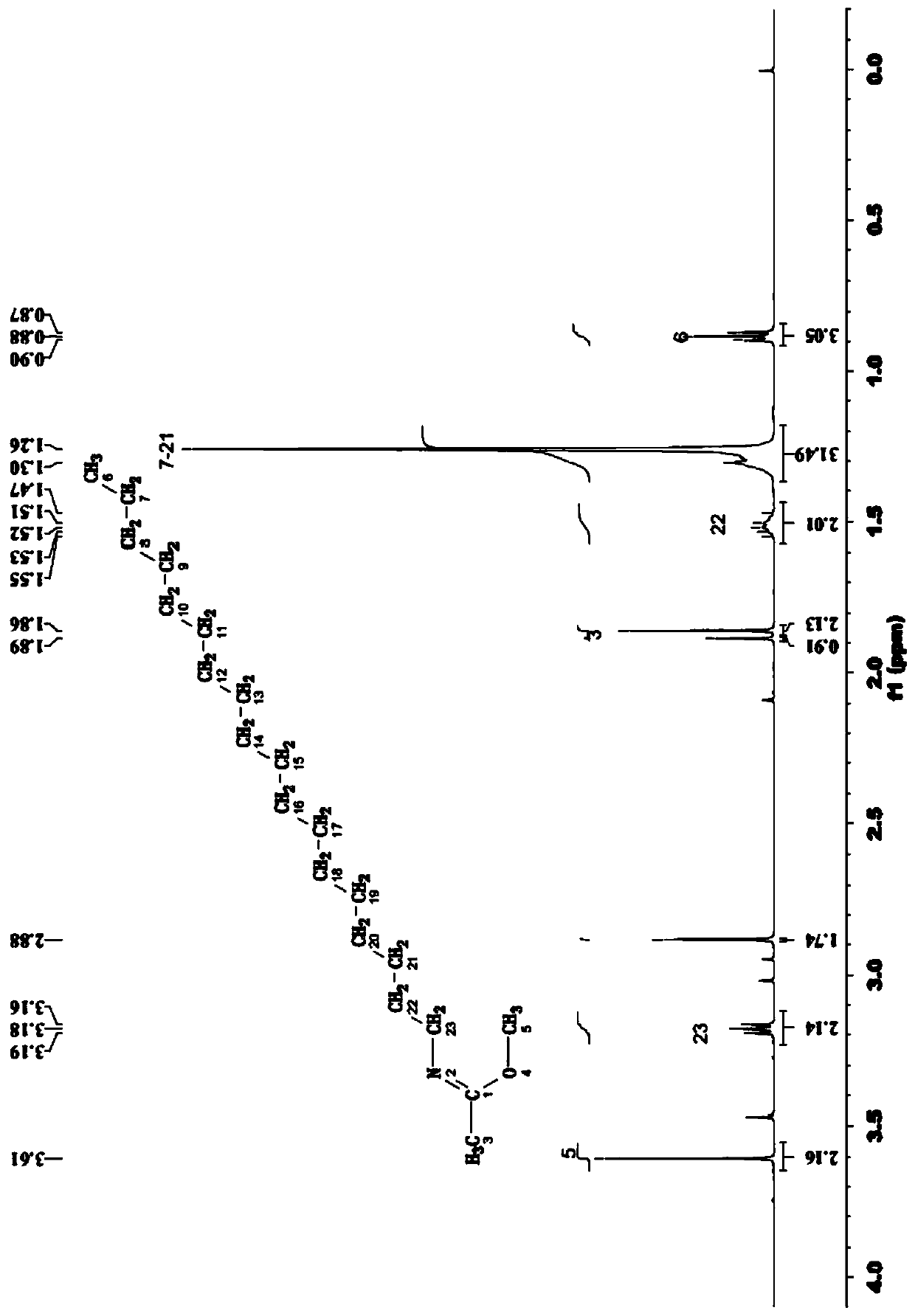

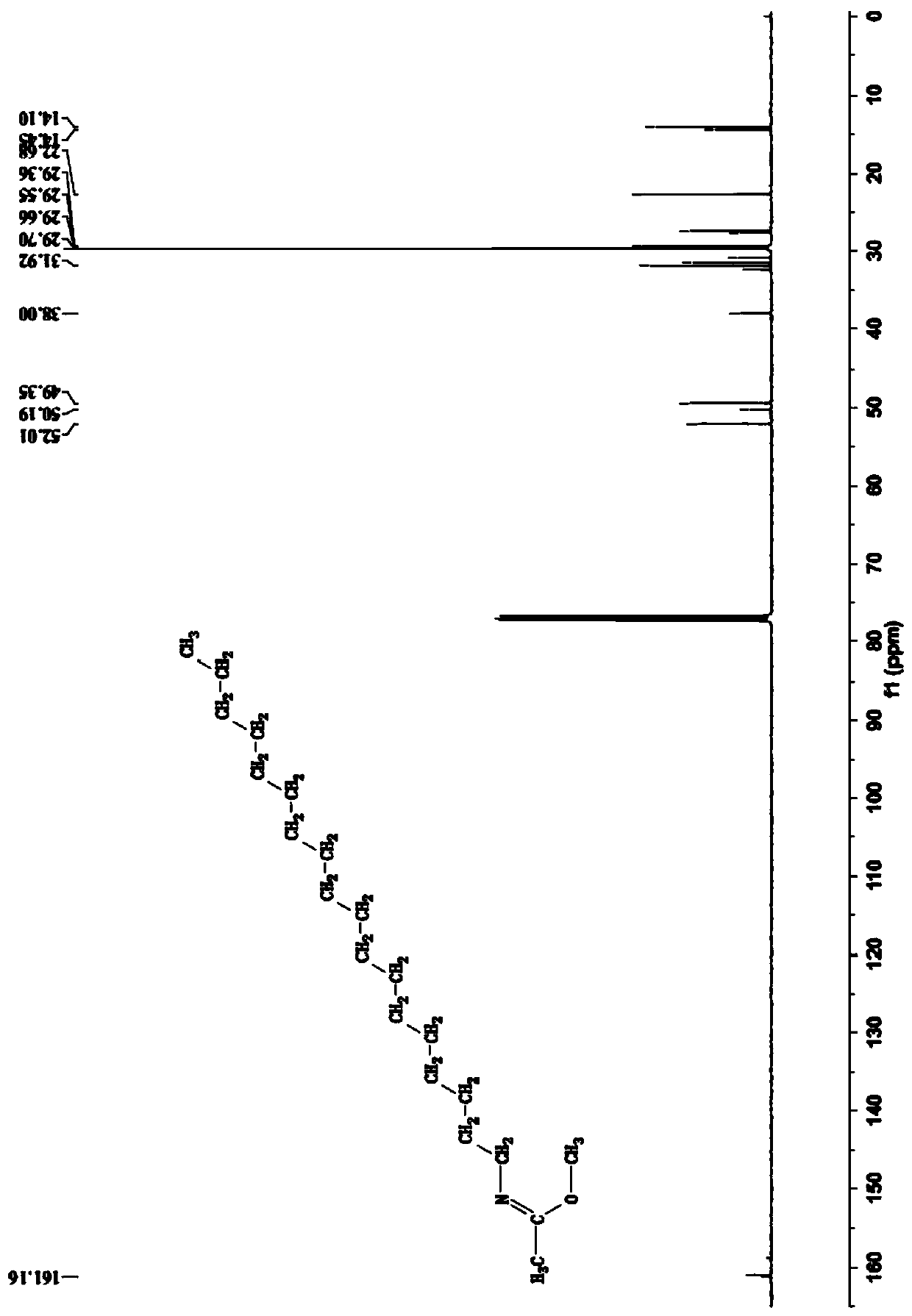

[0041] The mass spectrogram (diluted in acetonitrile) of the product synthesized in this embodiment is as follows: figure 1 ...

Embodiment 2

[0046] This embodiment provides a kind of methyl N-octadecyl acetimidate, which is synthesized through the following steps:

[0047] Weigh 2.83g of octadecylamine into a four-neck flask equipped with a condenser tube, a vacuum device and a thermometer, add 60mL of methanol, and heat in a constant temperature oil bath until octadecylamine is completely dissolved;

[0048] When the temperature rises to 50°C, slowly drop 2.02g of N,N-dimethylacetamide dimethyl acetal into the solution, and react at 0.1MPa for 8h;

[0049] TLC (V CHCl3:CH3OH =3:1) sample climbing board, no raw material point occurs, indicating that octadecylamine is fully converted;

[0050] Reduce the pressure to 0.08MPa, continue the reaction at 45°C for 15 minutes, and obtain a light yellow liquid product, which is methyl N-octadecylglycolimate, the N-octadecylglycolimate methyl ester of this example The yield of ester was 70.8%.

[0051] The above examples illustrate that in the synthetic method of N-octade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com