Process method for digesting plant oil by using carbon dioxide

A technology of carbon dioxide and process method, which is applied in the direction of fat oil/fat production and fat generation, which can solve the problems of vegetable oil processing quality, safety production impact, vegetable oil quality not up to high quality, combustion, explosion and toxic gas, etc., and achieve production cost Low production efficiency, high production efficiency, and the effect of purifying the production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

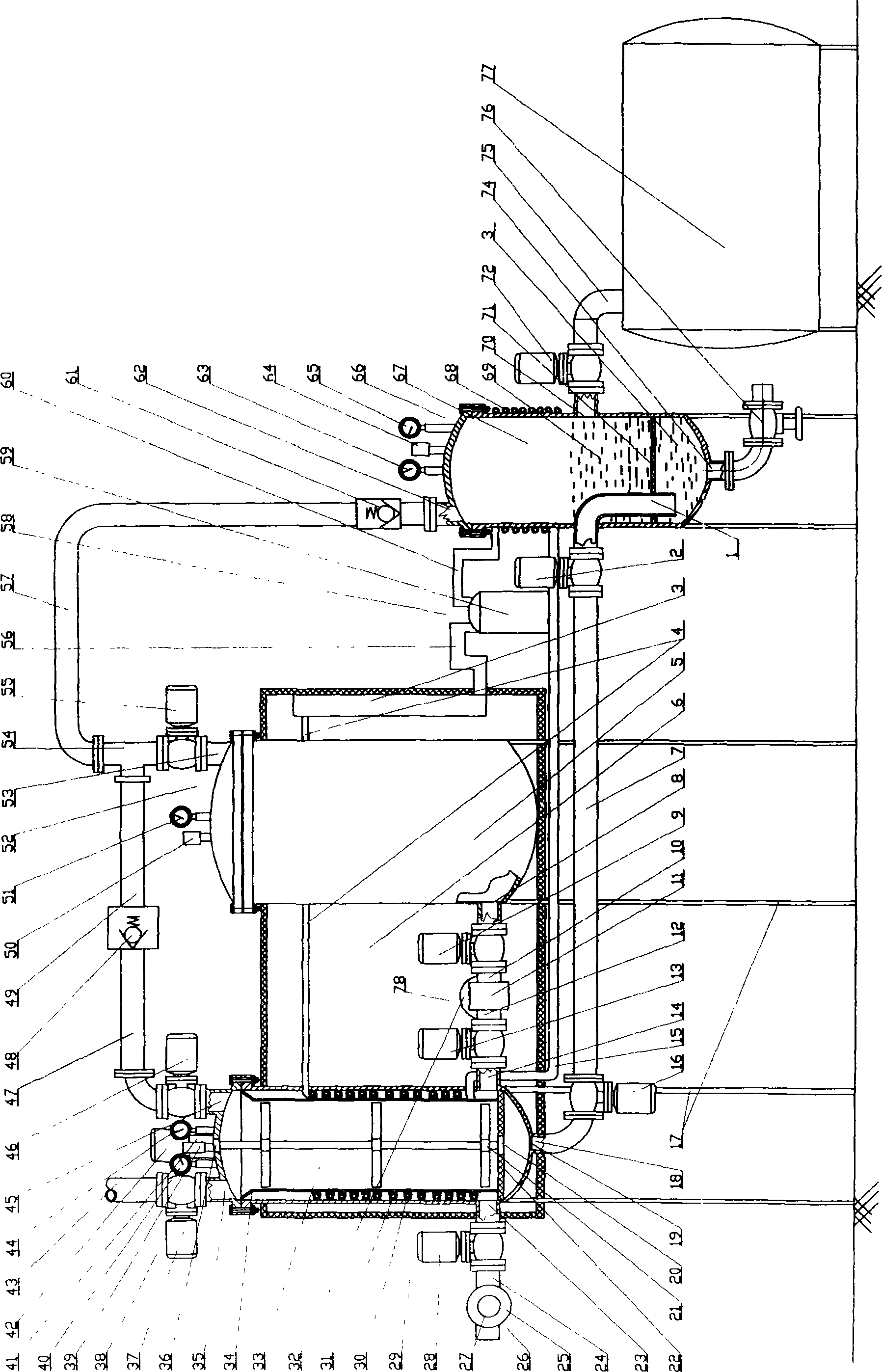

[0017] refer to figure 1 , figure 2 , image 3, the immersion body degreasing device 37 is mainly composed of a container tank 31, an inner tank 34, the sixth electromagnetic gate valve 37, a feed pipe 43, the first pressure gauge 40, the first safety valve 39, the first thermometer 44 and the seventh electromagnetic gate valve 46 Composition, immersion body degreasing device 38 is installed on the frame 17, and the middle part and the bottom of container tank 31 of immersion body degreasing device 38 are placed in the heat preservation chamber 6, and heat preservation chamber 6 is sealed and kept cold with insulation layer 29 around. The soaking body degreasing device 38 is mainly used for soaking and degreasing the plant grain powder and carbon dioxide. The top of the container tank 31 has a feed port 35 and an exhaust port 45, and the top of the container tank 31 is also equipped with a sixth electromagnetic gate valve 37, a feed pipe 43, a first pressure gauge 40, a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com