Hyper-gravity device for enhancing reaction by gas-liquid efficient premixing and application method thereof

An application method and supergravity technology, applied in the direction of mixing method, gas/steam and liquid mixing, chemical instruments and methods, etc., can solve the problem of high energy consumption of circulating hydrogen compressors, achieve enhanced mass transfer efficiency, high mass transfer efficiency, The effect of high mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

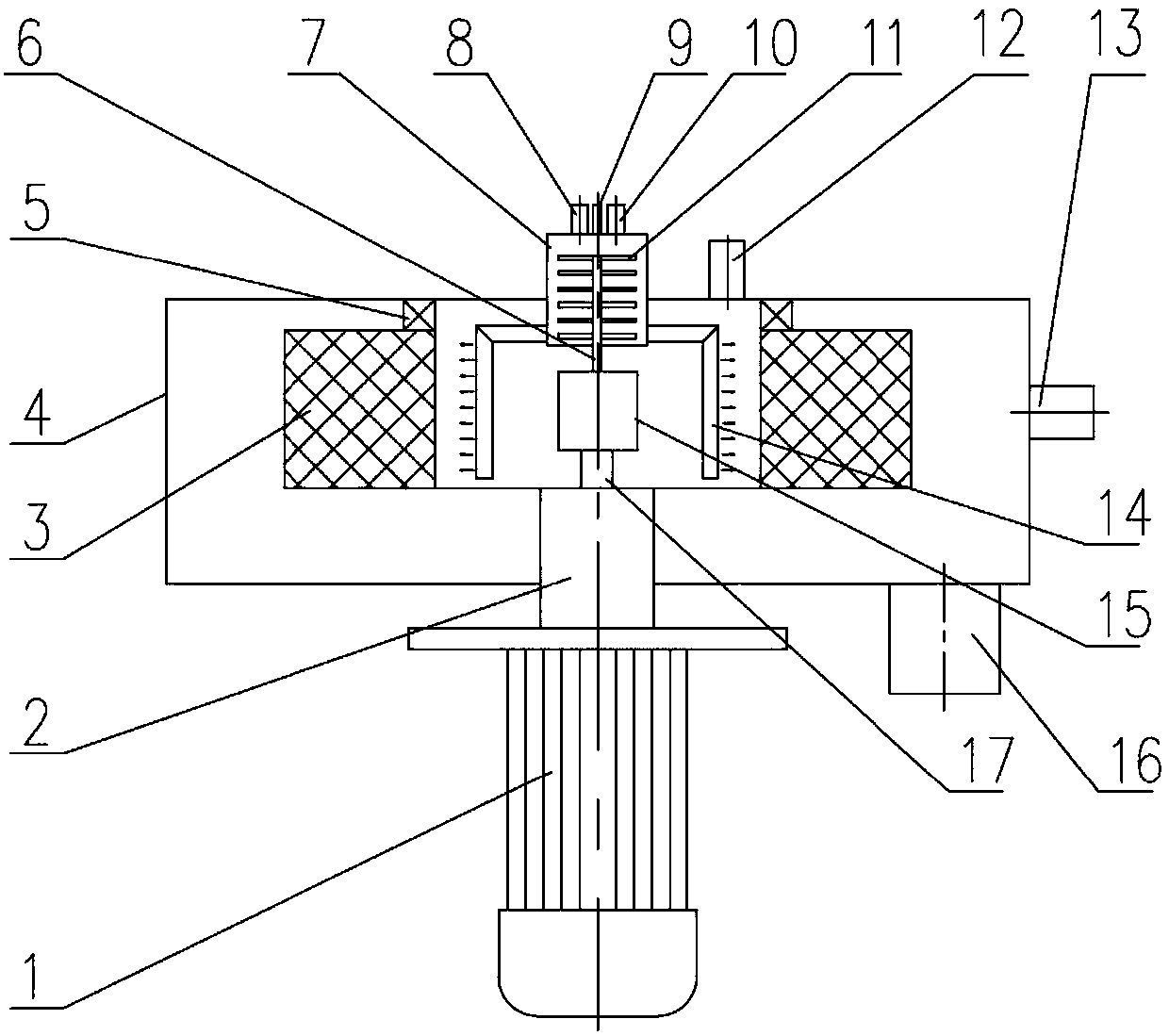

[0078] Example 1: Application of the supergravity device of the present invention in the enhanced decomposition of refractory organic matter

[0079] Hydroxyl radicals released when micro or nano bubbles burst can oxidize and decompose many organic pollutants. Compared with air micro-nano bubbles, ozone micro-nano bubbles remove the oxidation of hydroxyl radicals on the surface of the bubbles. Ozone itself has strong oxidative properties, which has a synergistic effect on the oxidative degradation of organic matter in wastewater, and enhances the treatment efficiency of organic matter.

[0080] The traditional aeration method generally uses the method of injecting macroscopic air bubbles into the water to increase oxygen in the water body. However, due to the rapid rise of the macroscopic air bubbles in the water, the gas-liquid mass transfer efficiency is low and the oxygenation effect is poor. In contrast, the rising speed of micro-nano bubbles in the water body is slow, and...

Embodiment 2

[0087] Embodiment 2: Application of the supergravity device of the present invention in glycerin oxidation reaction

[0088] The multiphase oxidation of glycerol to produce high value-added oxidation products is an important branch of the biodiesel industry chain. Glycerol can be converted into many high value-added chemical products through oxidation, such as dihydroxyacetone (DHA), hydroxypropionaldehyde, glyceraldehyde etc., and then processed into various products, showing new scientific significance and application value. Conventional production processes of these chemicals (such as potassium permanganate oxidation, nitric acid oxidation, and chromic acid oxidation) or low-yield fermentation processes have limited industrial applications and yields. The catalytic oxidation of glycerol is a complex process of multiple parallel reactions and series of reactions. Therefore, choosing an efficient reactor to effectively regulate the direction of catalytic oxidation of glycerol...

Embodiment 3

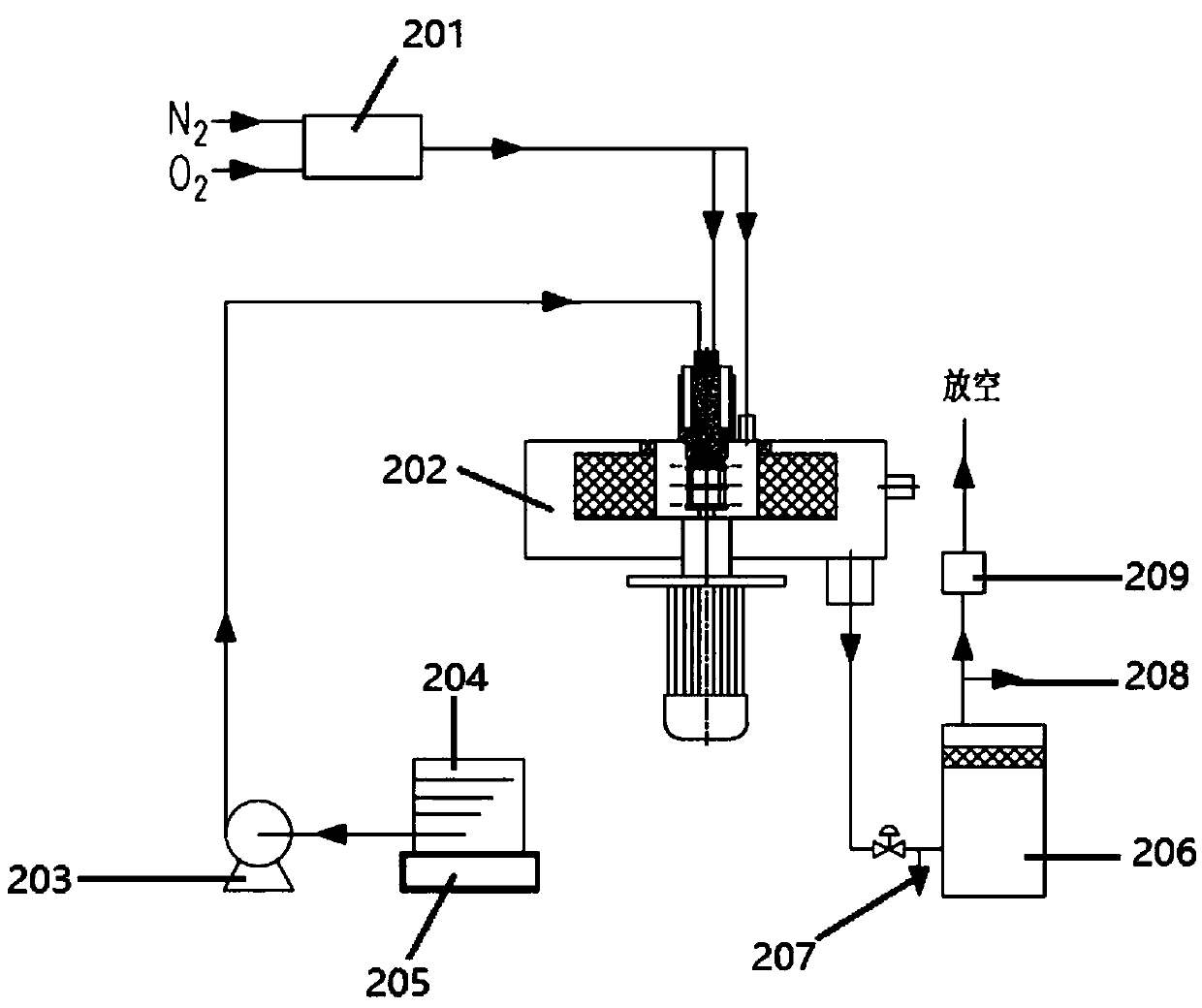

[0095] Embodiment 3: Application of the supergravity device of the present invention in liquid phase hydrogenation reaction

[0096] The traditional trickle bed hydrogenation technology adopts gas-liquid-solid three-phase, and the reaction only occurs on the surface of the catalyst wetted by the liquid phase, and the hydrogen must be dissolved in the liquid phase to react on the liquid-solid surface.

[0097] One of the requirements for liquid-phase hydrogenation is that the amount of hydrogen dissolved in the reactor feed should be higher than the amount of hydrogen required for the reaction. This can be achieved by adding hydrogen recirculation to the high-efficiency gas-liquid mixer, and the saturated liquid circulating material provides the reaction The required hydrogen can omit the circulating hydrogen compressor; because there is no need to dissolve hydrogen in the reactor, the gas-liquid mass transfer resistance in the entire reactor is eliminated; when designing the si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com