Ni-Mn-In-Co-Cu magnetic refrigeration alloy material and preparation method

An alloy material, ni-mn-in-co-cu technology, applied in the direction of magnetic materials, inorganic material magnetism, magnetic objects, etc., can solve the problem that the magnetocaloric effect cannot be applied in a wide range, and the phase transition temperature deviates from room temperature, etc. problem, to achieve the effect of abundant reserves, good performance stability and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

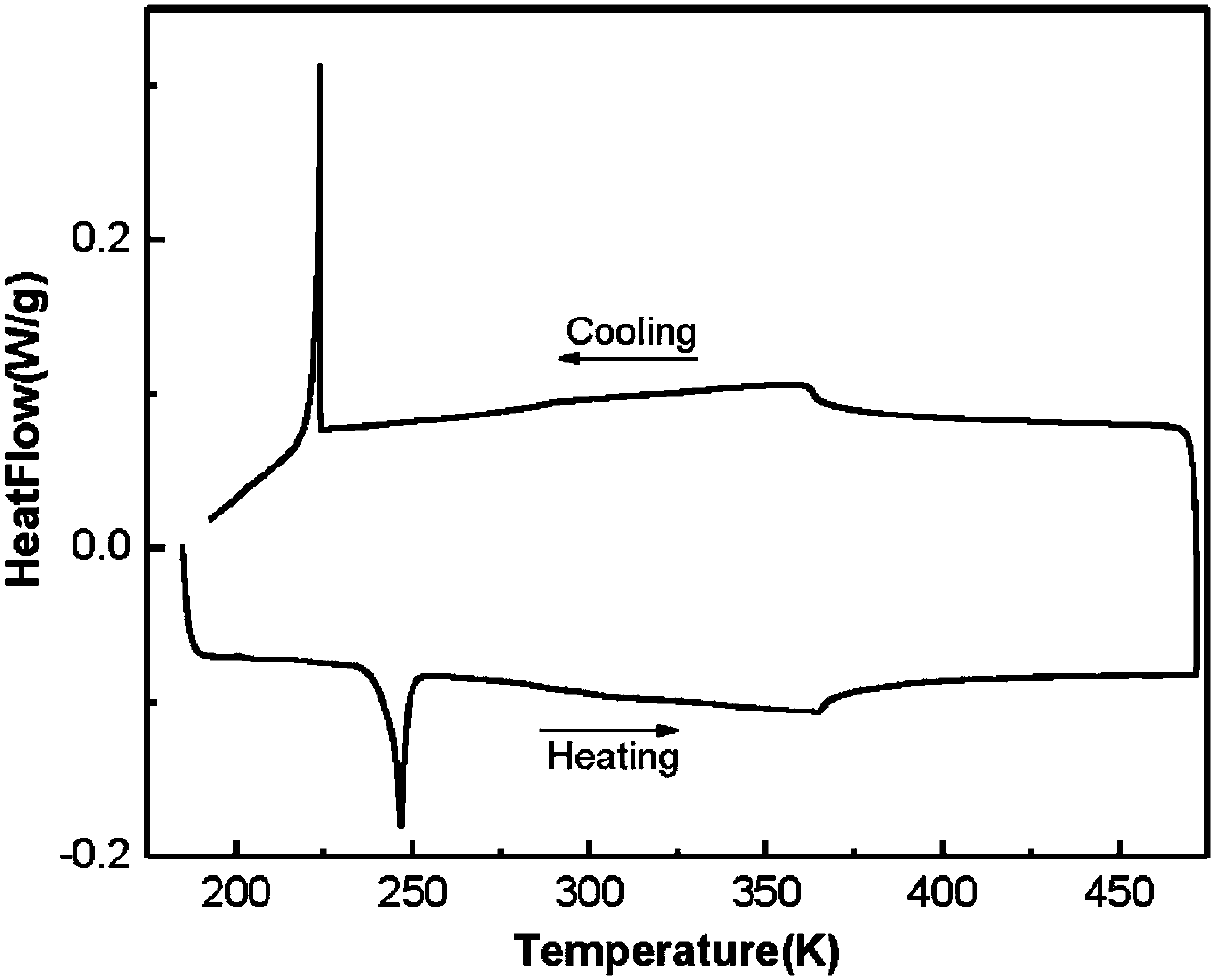

Embodiment 1

[0030] Ni-Mn-In-Co-Cu magnetic alloy, the sum of moles of elements in the alloy material is 100, and the molar ratio of elements is Ni:Mn:In:Co:Cu=46:36:14:3:1.

[0031] Ni 46 mn 36 In 14 co 3 Cu 1 The preparation method of magnetic alloy comprises the following steps:

[0032] (1) Raw material ratio: according to the molar ratio of Ni:Mn:In:Co:Cu=46:36:14:3:1;

[0033] (2) Preparation of polycrystalline ingots: the raw materials weighed in step (1) were placed in a water-cooled copper crucible of a vacuum arc melting furnace, and the cavity of the arc melting furnace was evacuated to 3×10 -3 ~5×10 -3 After Pa, pass in an inert protective gas of 0.05MPa, repeat smelting for 4 to 5 times, and conduct arc smelting under electromagnetic stirring to obtain a polycrystalline parent alloy with uniform composition;

[0034] (3) Heat treatment: Ni 46 mn 36 In 14 co 3 Cu 1 Alloy ingots were directly quenched in ice water after being kept at 1173K for 24h to obtain the Ni 4...

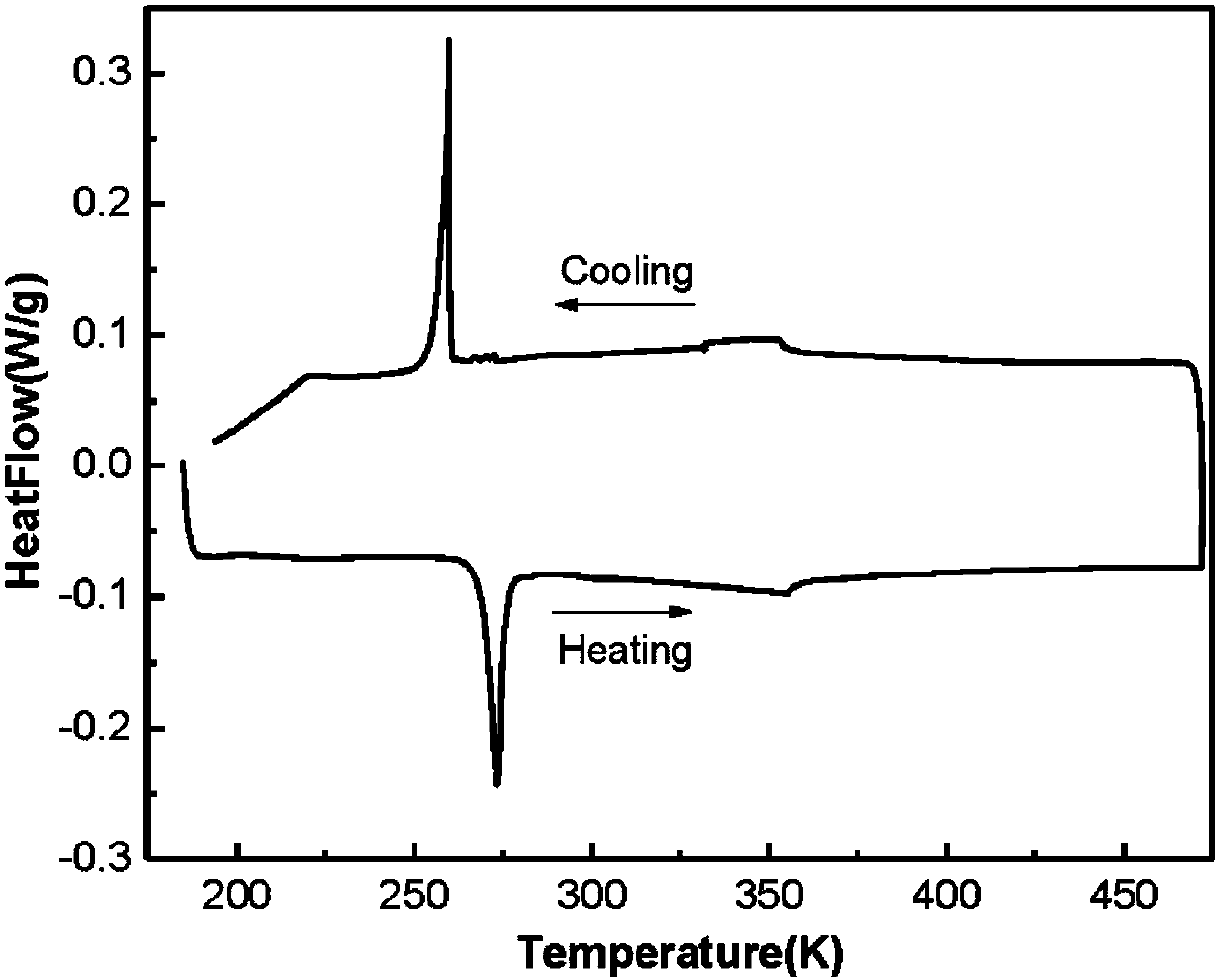

Embodiment 2

[0038] Ni-Mn-In-Co-Cu magnetic refrigeration alloy material, the sum of the moles of elements in the alloy material is 100, and the molar ratio of elements is Ni:Mn:In:Co:Cu=46:35:14:3:2 .

[0039] The preparation method of Ni-Mn-In-Co-Cu magnetic refrigeration alloy material comprises the following steps:

[0040] (1) Raw material ratio: according to the molar ratio batching of Ni:Mn:In:Co:Cu=46:35:14:3:2;

[0041] (2) Preparation of polycrystalline ingots: the raw materials weighed in step (1) were placed in a water-cooled copper crucible of a vacuum arc melting furnace, and the cavity of the arc melting furnace was evacuated to 3×10 -3 ~5×10 -3 After Pa, pass in an inert protective gas of 0.05MPa, repeat smelting for 4 to 5 times, and conduct arc smelting under electromagnetic stirring to obtain a polycrystalline parent alloy with uniform composition;

[0042] (3) Heat treatment: Ni 46 mn 35 In 14 co 3 Cu 2 Alloy ingots were directly quenched in ice water after bein...

Embodiment 3

[0046] Ni-Mn-In-Co-Cu magnetic refrigeration alloy material, the sum of the moles of elements in the alloy material is 100, and the molar ratio of elements is Ni:Mn:In:Co:Cu=46:34:14:3:3 .

[0047] Ni 46 mn 34 In 14 co 3 Cu 3 The preparation method of magnetic alloy comprises the following steps:

[0048] (1) Raw material ratio: according to the chemical formula Ni 46 mn 34 In 14 co 3 Cu 3 The molar ratio ingredients;

[0049] (2) Preparation of polycrystalline ingots: the raw materials weighed in step (1) were placed in a water-cooled copper crucible of a vacuum arc melting furnace, and the cavity of the arc melting furnace was evacuated to 3×10 -3 ~5×10 -3 After Pa, pass in an inert protective gas of 0.05MPa, repeat smelting for 4 to 5 times, and conduct arc smelting under electromagnetic stirring to obtain a polycrystalline parent alloy with uniform composition;

[0050] (3) Heat treatment: Ni 46 mn 34 In 14 co 3 Cu 3 Alloy ingots were directly quenched in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com