Ni-Co-Mn-In-Ge magnetic refrigeration alloy material and preparing method thereof

An alloy material, magnetic refrigeration technology, applied in the direction of magnetic materials, inorganic material magnetism, magnetic objects, etc., can solve the problem of unsatisfactory magnetocaloric effect, etc., and achieve the effects of abundant reserves, good refrigeration capacity, and non-toxic thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

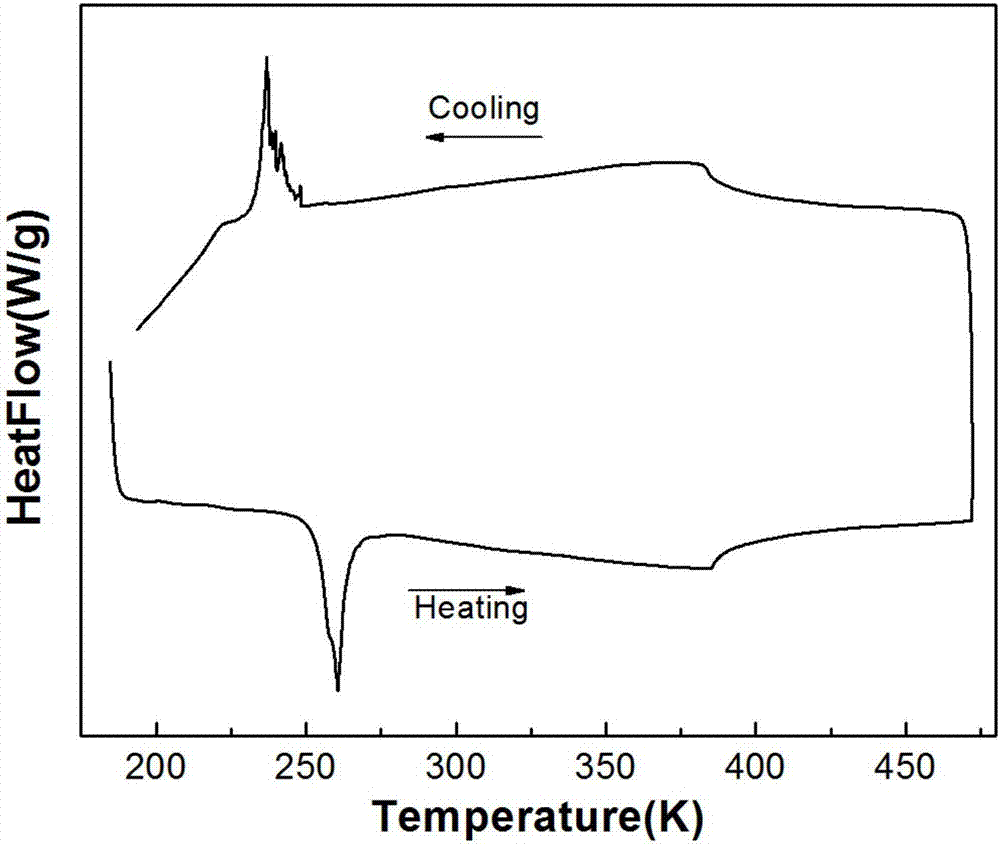

Image

Examples

Embodiment 1

[0031] Ni-Co-Mn-In-Ge magnetic alloy, the sum of the moles of elements in the alloy material is 100, and the molar ratio of elements is Ni:Co:Mn:In:Ge=45:5:36.5:12.5:1.

[0032] Ni 45 co 5 mn 36.5 In 12.5 Ge 1 The preparation method of magnetic alloy comprises the following steps:

[0033] (1) Raw material ratio: according to the molar ratio of Ni:Co:Mn:In:Ge=45:5:36.5:12.5:1;

[0034] (2) Preparation of polycrystalline ingots: the raw materials weighed in step (1) were placed in a water-cooled copper crucible of a vacuum arc melting furnace, and the cavity of the arc melting furnace was evacuated to 3×10 -3 ~5×10 -3 After Pa, pass in an inert protective gas of 0.05MPa, repeat smelting for 4 to 5 times, and perform arc smelting under electromagnetic stirring to obtain a polycrystalline parent alloy with uniform composition;

[0035] (3) Heat treatment: Ni 45co 5 mn 36.5 In 12.5 Ge 1 Alloy ingots were directly quenched in ice water after being kept at 1173K for 24h ...

Embodiment 2

[0039] Ni-Co-Mn-In-Ge magnetic refrigeration alloy material, the sum of the moles of elements in the alloy material is 100, and the molar ratio of elements is Ni:Co:Mn:In:Ge=45:5:36.5:11.5:2 .

[0040] The preparation method of Ni-Mn-In-Co-Cu magnetic refrigeration alloy material comprises the following steps:

[0041] (1) Raw material ratio: according to the molar ratio batching of Ni:Co:Mn:In:Ge=45:5:36.5:11.5:2;

[0042] (2) Preparation of polycrystalline ingots: the raw materials weighed in step (1) were placed in a water-cooled copper crucible of a vacuum arc melting furnace, and the cavity of the arc melting furnace was evacuated to 3×10 -3 ~5×10 -3 After Pa, pass in an inert protective gas of 0.05MPa, repeat smelting for 4 to 5 times, and conduct arc smelting under electromagnetic stirring to obtain a polycrystalline parent alloy with uniform composition;

[0043] (3) Heat treatment: Ni 45 co 5 mn 36.5 In 11.5 Ge 2 Alloy ingots were directly quenched in ice wate...

Embodiment 3

[0047] Ni-Co-Mn-In-Ge magnetic refrigeration alloy material, the sum of the moles of elements in the alloy material is 100, and the molar ratio of elements is Ni:Co:Mn:In:Ge=45:5:36.5:10.5:3 .

[0048] Ni 45 co 5 mn 36.5 In 10.5 Ge 3 The preparation method of magnetic alloy comprises the following steps:

[0049] (1) Raw material ratio: according to the chemical formula Ni 45 co 5 mn 36.5 In 10.5 Ge 3 The molar ratio ingredients;

[0050] (2) Preparation of polycrystalline ingots: the raw materials weighed in step (1) were placed in a water-cooled copper crucible of a vacuum arc melting furnace, and the cavity of the arc melting furnace was evacuated to 3×10 -3 ~5×10 -3 After Pa, pass in an inert protective gas of 0.05MPa, repeat smelting for 4 to 5 times, and conduct arc smelting under electromagnetic stirring to obtain a polycrystalline parent alloy with uniform composition;

[0051] (3) Heat treatment: Ni 45 co 5 mn 36.5 In 10.5 Ge 3 Alloy ingots were dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com