Ferromanganese-based magnetic composite material and design method and manufacturing method thereof

A composite material and design method technology, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve the problem of small working temperature range and achieve the effect of large working temperature span value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

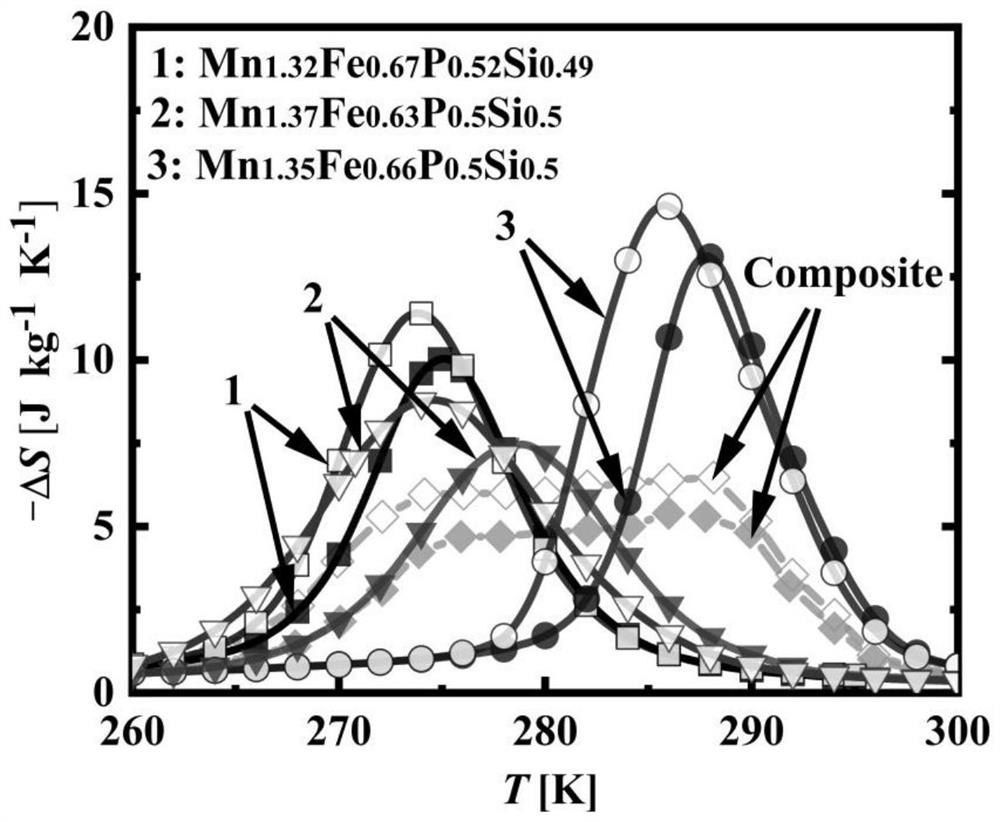

[0111] The design of embodiment 1-ferromanganese-based magnetic composite material

[0112] Step 1: The first layer of ferromanganese-based magnetic material, the second layer of ferromanganese-based magnetic material and the third layer of ferromanganese-based magnetic material are Mn 1.32 Fe 0.67 P 0.52 Si 0.49 , Mn 1.37 Fe 0.63 P 0.5 Si 0.5 and Mn 1.35 Fe 0.66 P 0.5 Si 0.5 , to establish the relationship between the magnetic entropy and isothermal magnetic entropy change of the ferromanganese-based magnetic composite material and the applied magnetic field strength, temperature, and the molar ratio of the three-layer ferromanganese-based magnetic material:

[0113]

[0114]

[0115] Step 2: Establish the following equations to compound and optimize the three-layer ferromanganese-based magnetic material:

[0116]

[0117]

[0118] In step 1 and step 2, z k is the molar ratio of each layer of ferromanganese-based magnetic material to the total ferrom...

Embodiment 2

[0130] Manufacture of embodiment 2-ferromanganese-based magnetic composite material

[0131] The magnetic material Mn with a molar ratio of 0.22:0.33:0.45 1.32 Fe 0.67 P 0.52 Si 0.49 , Mn 1.37 Fe 0.63 P 0.5 Si 0.5 , Mn 1.35 Fe 0.66 P 0.5 Si 0.5 The magnetic material sheets are respectively formed, and the ferromanganese-based magnetic composite material is formed by stacking the magnetic material sheets in sequence. Specific steps are as follows:

[0132] a) Under an argon atmosphere, Mn 1.32 Fe 0.67 P 0.52 Si 0.49 , Mn 1.37 Fe 0.63 P 0.5 Si 0.5 , Mn 1.35 Fe 0.66 P 0.5 Si 0.5 The required raw materials are mixed, and after mixing, they are ball milled for 10 hours and pressed into a flake green body; sealed in a quartz ampoule and placed in an argon atmosphere.

[0133] b) Sinter the sheet green body at 1373K for 2h, then anneal at 1123K for 20h, and then cool to room temperature in a vacuum sintering furnace. Then it is annealed for the second time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com