Inferior residual oil suspension bed hydrogenation conversion method

A hydrogenation conversion and suspension bed technology, applied in the chemical industry, can solve the problems that affect the application of the technology and the start-up period, low desulfurization and demetallization, coking in the reactor, etc., and achieve the goal of improving the conversion rate of residual oil, reducing coking, and improving the conversion rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1, suspension bed hydroconversion of vacuum residue

[0046] Using CNOOC Huizhou Refinery vacuum residue as raw material (the properties of the raw material are shown in Table 1), the vacuum residue was subjected to suspension bed hydroconversion according to the following steps:

[0047] Table 1. Raw material property data

[0048]

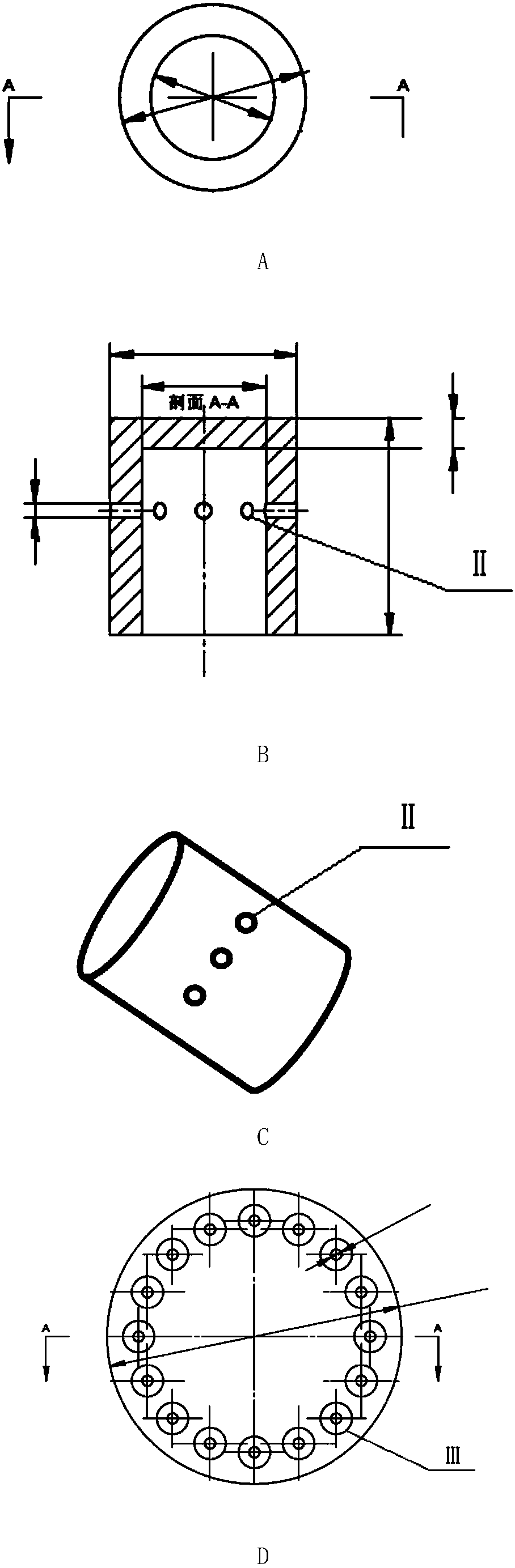

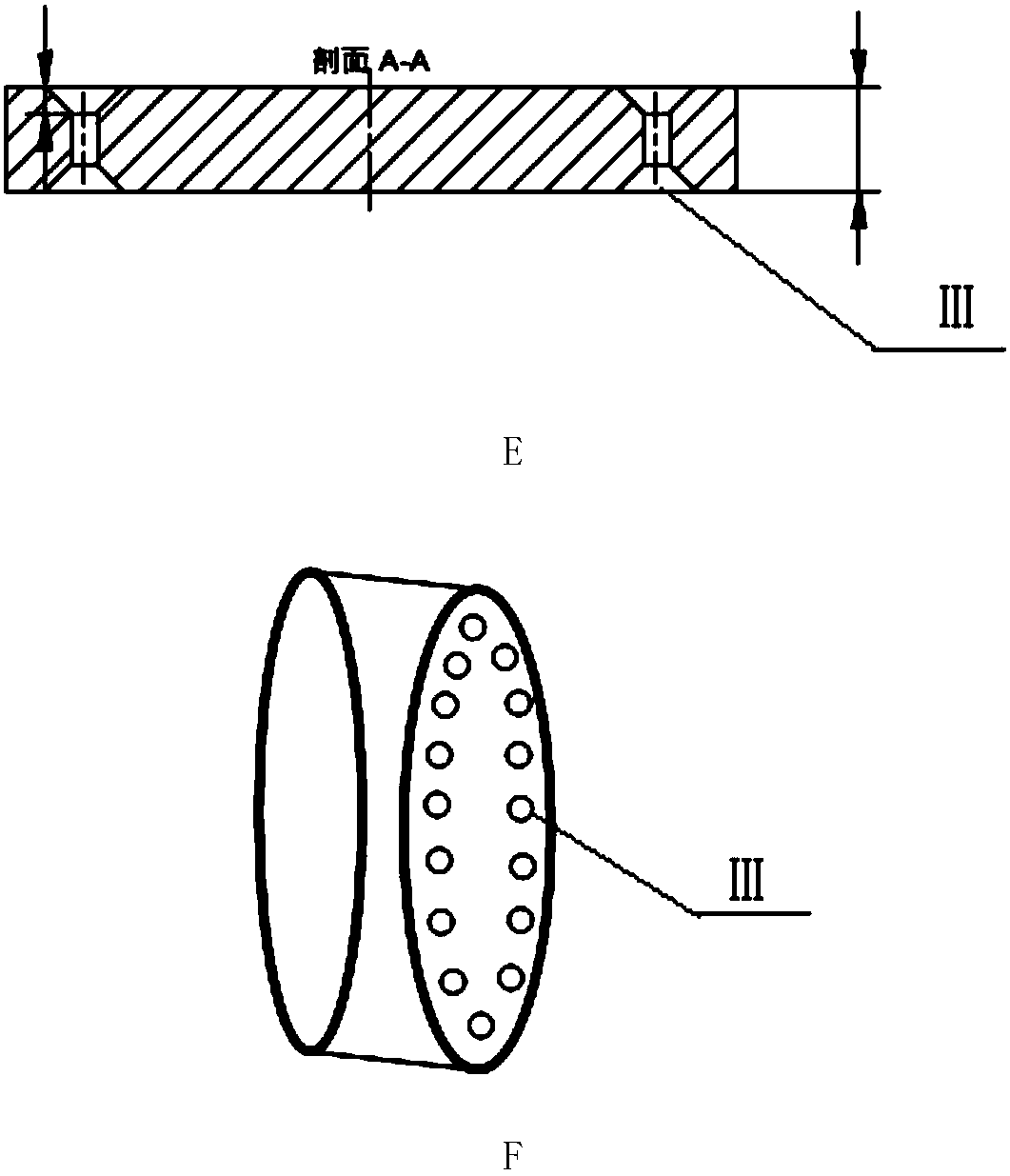

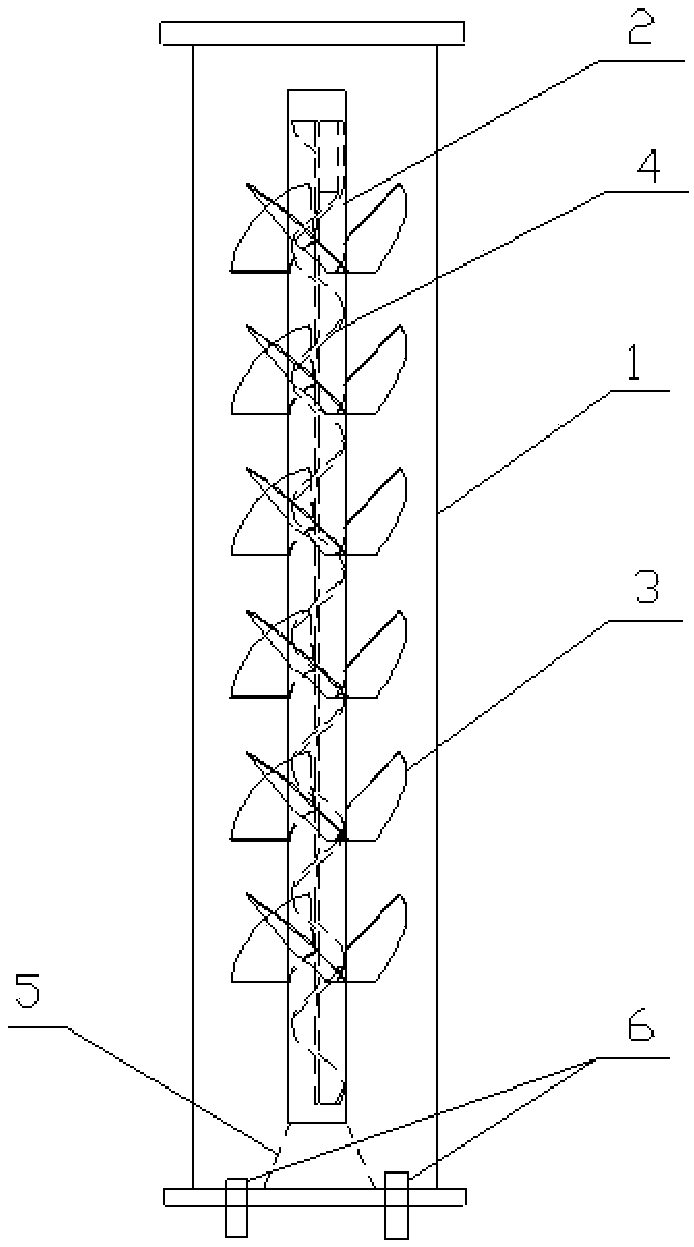

[0049] Use the raw material pump according to 0.5h -1 The volumetric space velocity contains 300ppm catalyst residue oil raw material and hydrogen mixed according to the volume ratio of 1:1000 and then enters the preheating furnace, heated to 180°C by the preheating furnace and enters the radial and axial secondary distributor, after efficient distribution Entering the air-lift loop reactor, in the air-lift loop reactor, the residual oil raw material containing the catalyst and the hydrogen gas go up the axial rotation of the reactor, and the inferior residual oil undergoes a chemical reaction in the reactor, the reactor pre...

Embodiment 2

[0051] Example 2, Suspension bed hydroconversion of vacuum residue

[0052] Using CNOOC Huizhou Refinery vacuum residue as raw material (the properties of the raw material are shown in Table 1), the vacuum residue was subjected to suspension bed hydroconversion according to the following steps:

[0053] Use the raw material pump according to 1.0h -1 The volume space velocity contains 300ppm of catalyst raw material and hydrogen mixed according to the volume ratio of 1:1000, then enters the preheating furnace, is heated to 180 ° C by the preheating furnace, enters the radial and axial secondary distributor, and enters the gas lift after efficient distribution Type loop reactor, in the air-lift loop reactor, the residual oil raw material containing the catalyst and the hydrogen gas go up the axial rotation of the reactor, and the low-quality residual oil undergoes a chemical reaction in the reactor, the reactor pressure is 14Mpa, and the temperature is 440°C. The gas and hydrog...

Embodiment 3

[0055] Example 3, Suspension bed hydroconversion of vacuum residue

[0056] Using CNOOC Huizhou Refinery vacuum residue as raw material (the properties of the raw material are shown in Table 1), the vacuum residue was subjected to suspension bed hydroconversion according to the following steps:

[0057] Use the raw material pump according to 0.5h -1 The volumetric space velocity contains 300ppm catalyst residue raw material and hydrogen mixed according to 1:1000 and then enters the preheating furnace, heated to 180 ℃ by the preheating furnace, enters the radial and axial secondary distributor, and enters the gas lift after efficient distribution Type loop reactor, in the air-lift loop reactor, the residual oil raw material containing the catalyst and the hydrogen gas go up the axial rotation of the reactor, and the low-quality residual oil undergoes a chemical reaction in the reactor, the reactor pressure is 16Mpa, and the temperature is 460°C. The gas and hydrogen come out f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conversion rate | aaaaa | aaaaa |

| Conversion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com