Silicone rubber tackifier, liquid two-component addition type silicone rubber prepared therefrom and application thereof

A silicone rubber, addition molding technology, used in adhesives, polymer adhesive additives, non-polymer adhesive additives, etc. Quantity and other issues to achieve the effect of good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

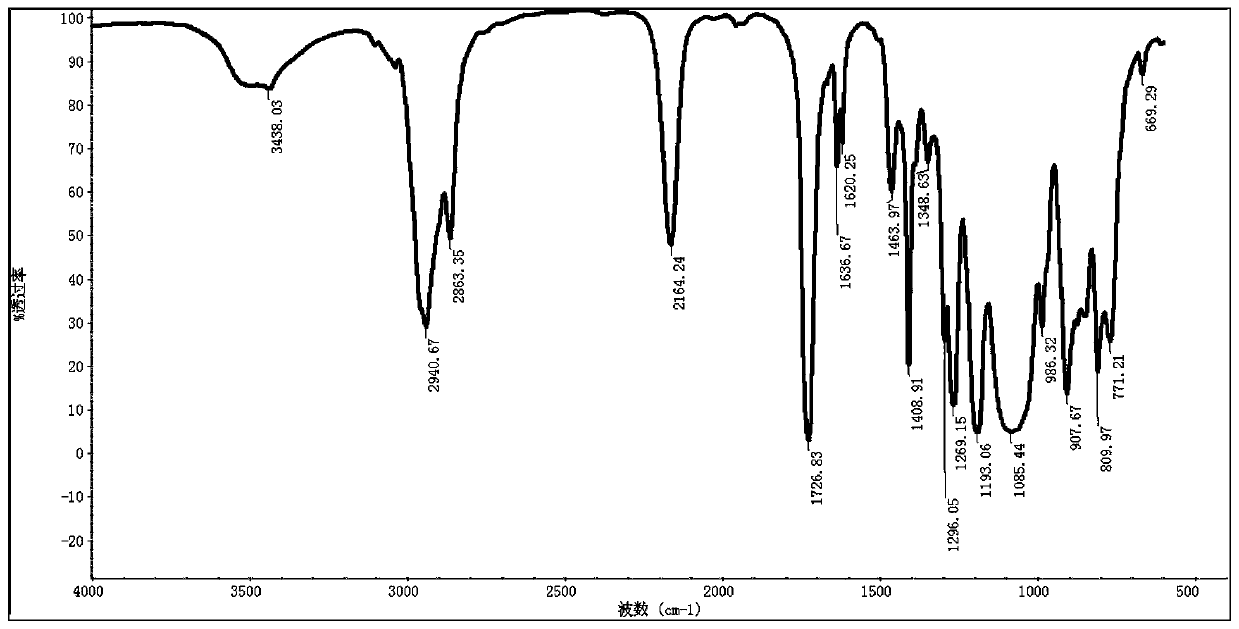

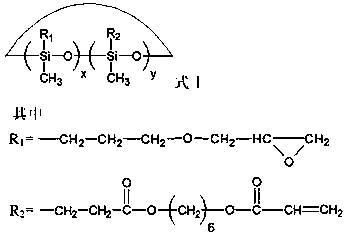

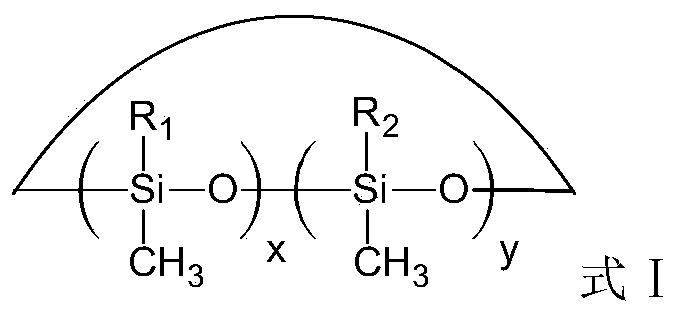

[0043] The preparation of embodiment 1 addition type silicone rubber tackifier

[0044] Add 120 parts by mass of tetramethylcyclotetrasiloxane, 38 parts by mass of allyl glycidyl ether, and 0.4 parts by mass of platinum catalyst (platinum content is 3000ppm) into the three-necked flask, heat and stir in a water bath at 50°C for 30 minutes, drop into 76 parts by mass of allyl glycidyl ether (dropped in about 60 minutes), heated and stirred in a water bath at 50°C for 30 minutes, added 0.1 parts by mass of hydroquinone and 226 parts by mass of 1,6-hexanediol diacrylate, and placed in a water bath at 50°C After heating and stirring at medium temperature for 30 minutes, the temperature of the water bath was raised to 80° C., and after stirring for 4.5 hours, 0.1 parts by mass of hydroquinone was added and stirred for 10 minutes. Cool to room temperature, place at room temperature for 12 hours, add 20 parts by mass of activated carbon and stir for 30 minutes, and filter to separate...

Embodiment 2

[0050] Embodiment 2 Preparation of liquid two-component addition type silicone rubber

[0051] 100 parts of vinyl-terminated polydimethylsiloxane with a viscosity (25°C) of 300 mPa·s, 98 parts of calcium carbonate whose surface was treated with a silane coupling agent, and 2 parts of gas-phase white carbon whose surface was treated with a silane coupling agent Black, stir and mix uniformly under vacuum conditions in a planetary machine, add 0.5 part of tackifier prepared in Example 1, 4 parts of hydrogen-containing silicone oil with a hydrogen content of 0.75%, 0.05 part of inhibitor (3,5-dimethyl base-1-ethynyl-3-alcohol), stir and mix evenly in a planetary machine, then add 0.5 parts of a platinum catalyst with a platinum content of 3000ppm, stir and mix evenly, and obtain a double Component addition silicone rubber.

[0052] According to GB / T7124-2008, the prepared two-component addition-type silicone rubber with adhesiveness to metal and non-metal materials was respective...

Embodiment 3

[0053] Embodiment 3 Preparation of liquid two-component addition type silicone rubber

[0054] Stir and mix 100 parts of vinyl-terminated polydimethylsiloxane with a viscosity (25°C) of 300mPa·s and 200 parts of calcium carbonate whose surface has been treated with a silane coupling agent in a planetary machine under vacuum conditions, and add 3 parts The tackifier obtained in Example 1, 8 parts of hydrogen-containing silicone oil with a hydrogen content of 0.36%, 0.1 part of inhibitor (1-hexynyl-1-cyclohexanol), after stirring and mixing uniformly in a planetary machine, Then add 0.05 parts of platinum catalyst with a platinum content of 3000ppm and stir to mix evenly to obtain a two-component addition type silicone rubber with adhesion to both metal and non-metal materials.

[0055] According to GB / T7124-2008, the prepared two-component addition-type silicone rubber, which is adhesive to both metal and non-metal materials, is respectively bonded to aluminum, stainless steel,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com