Moonpool, maritime device with same, and sliding device arranged on moonpool

A technology of sliding device and moon pool, which is applied in the direction of floating buildings, etc., can solve the problems of affecting equipment functions, damage of steel wire ropes or other components, and failure to meet the limit operation requirements of water-resisting casings, etc., and achieves small occupation area and normal increase The effect of the swinging area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

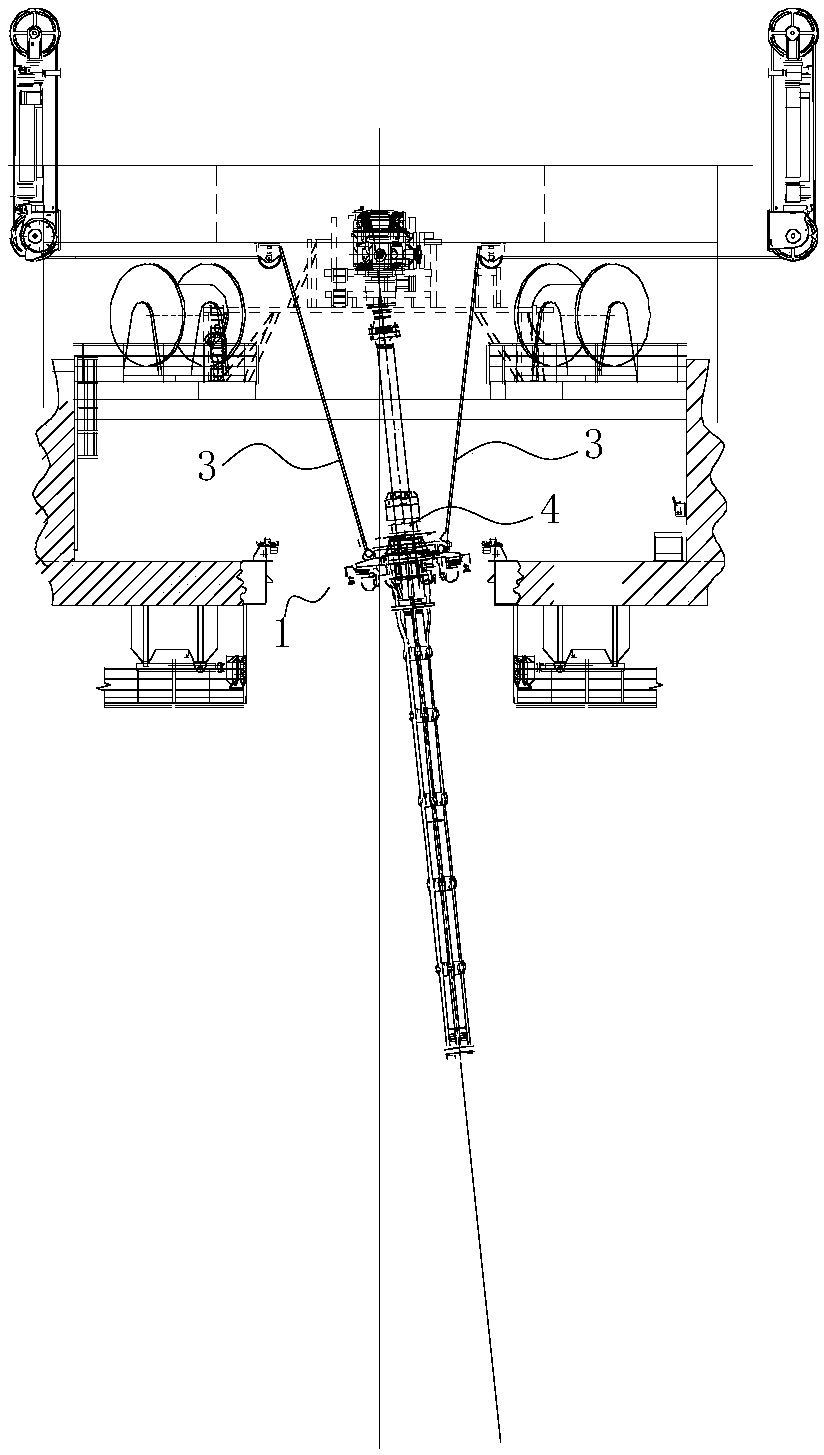

[0028] The following references are attached figure 1 to attach Figure 8 , to further elaborate on various embodiments of the present invention.

[0029] as attached figure 1 , attached Figure 7 As shown, one aspect of the present invention provides a moon pool formed on the operating surface or deck of the offshore equipment to provide an operating space for extending the water riser 4 into the seabed when the offshore equipment performs subsea drilling. It includes: a first space 1 set on the offshore equipment for drilling operations, and also includes: a second space 2 respectively corresponding to two sides formed in the length direction of the first space 1, and the bottom of the second space 2 has Through hole, the second space 2 communicates with the first space 1 .

[0030] In the present invention, the second space 2 is respectively formed on the two sides of the first space 1 of the moon pool in the length direction, so that the width of the moon pool can be i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com