Zero energy consumption new energy automobile heat management system

A new energy vehicle and thermal management system technology, applied in the field of new energy vehicle thermal management system, can solve the problems of not being able to transmit heat to the outside world and consuming electricity, and achieve the effect of improving battery life and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

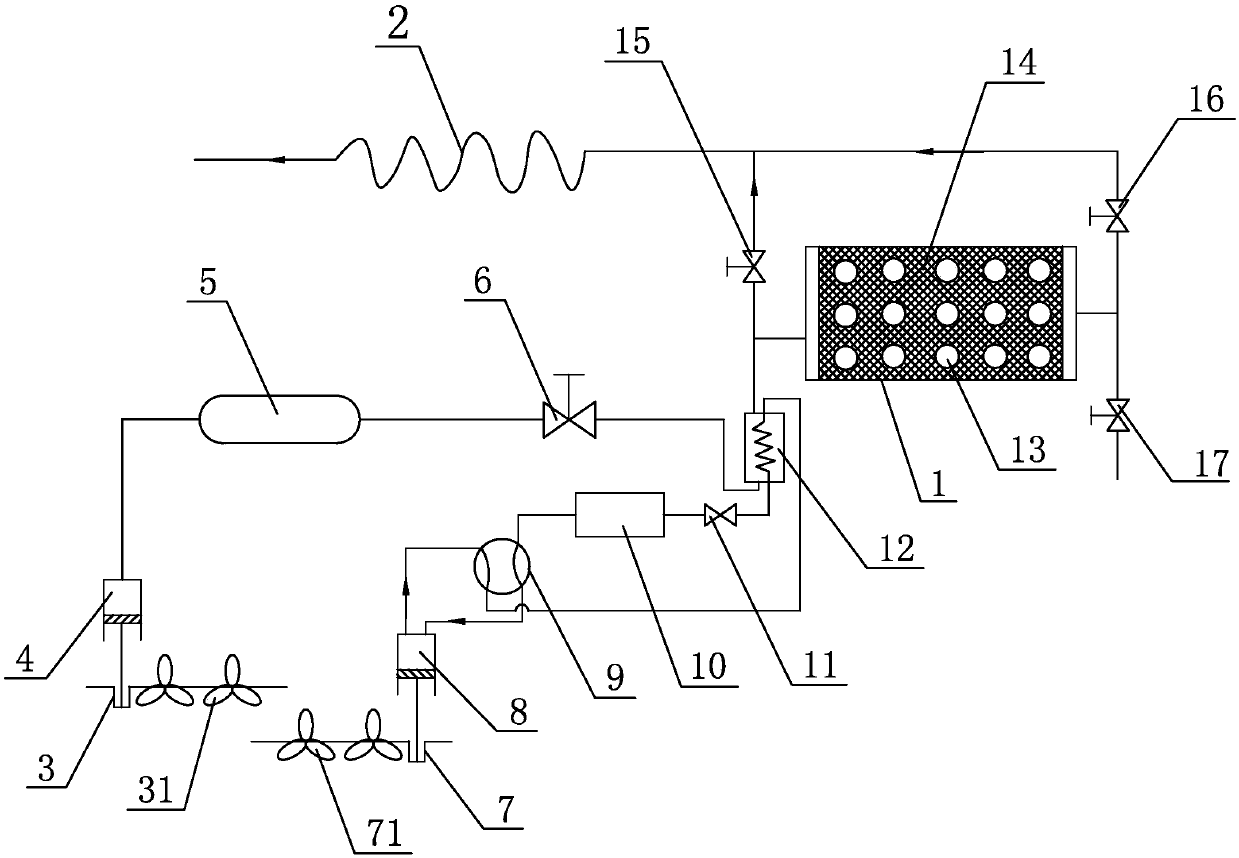

[0018] As shown in the figure, a zero-energy new energy vehicle thermal management system includes an air compression system, a cooling / heating system, a first wind energy conversion mechanism, a second wind energy conversion mechanism, a battery box 1 and a coil 2, The first wind energy conversion mechanism includes a first crankshaft 3 and multiple sets of first fan blades 31, the first fan blades 31 are coaxially fixed on the first crankshaft 3, and the air compression system includes an air compressor 4, an air storage tank 5 and a regulating valve 6. The piston rod of the air compressor 4 is hinged to the first crankshaft 3, the air storage tank 5 is respectively connected to the air compressor 4 and the regulating valve 6, and the second wind energy conversion mechanism includes the second crankshaft 7 and multiple sets of second wind tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com