Cable cooling apparatus

A cooling device and cable technology, applied in the direction of electrical components, etc., can solve the problems of power consumption, processing aging, ignition of contact objects, etc., achieve rapid cooling effect, rapid cooling and cooling, and prevent bending damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

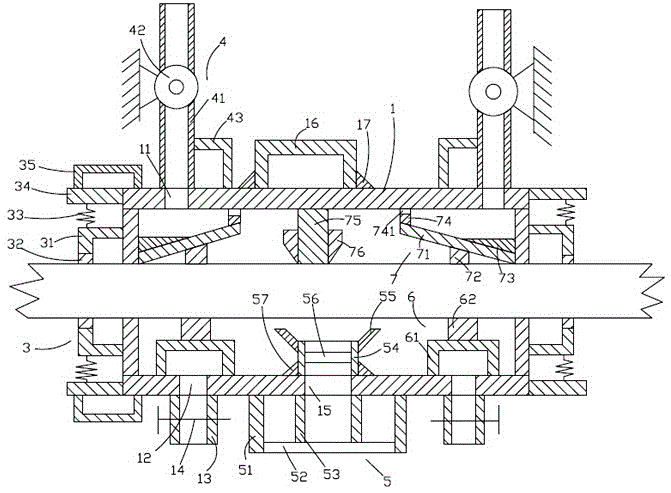

[0018] like figure 1 As shown in the figure, the cable cooling device of the present invention comprises a frame body 1, a fixing device 3 located on the left and right sides of the frame body 1, an air suction device 4 located above the frame body 1, and an inlet device located below the frame body 1. The air device 5 , the water tank device 6 located in the frame body 1 , and the air collecting device 7 located above the water tank device 6 .

[0019] like figure 1 As shown, the frame body 1 is a hollow cuboid, the frame body 1 is placed horizontally, and the frame body 1 is provided with first through holes 11 located on the left and right sides of the upper surface, and second through holes 11 located on the left and right sides of the lower surface. Two through holes 12 , a first pipe 13 located below the second through hole 12 , a first valve 14 disposed on the first pipe 13 , and a third through hole located between the second through holes 12 15. The holding frame 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com