Bolt bar part circular groove rolling strengthening method and rolling strengthening device for turning lathe

A technology of strengthening device and annular groove, which is applied in the field of rolling strengthening of annular grooves of bolt shanks, can solve the problems of unsatisfactory rolling strengthening method, poor consistency of rolling dimensions, long time for roller installation and adjustment, etc. Compact, consistent, and high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

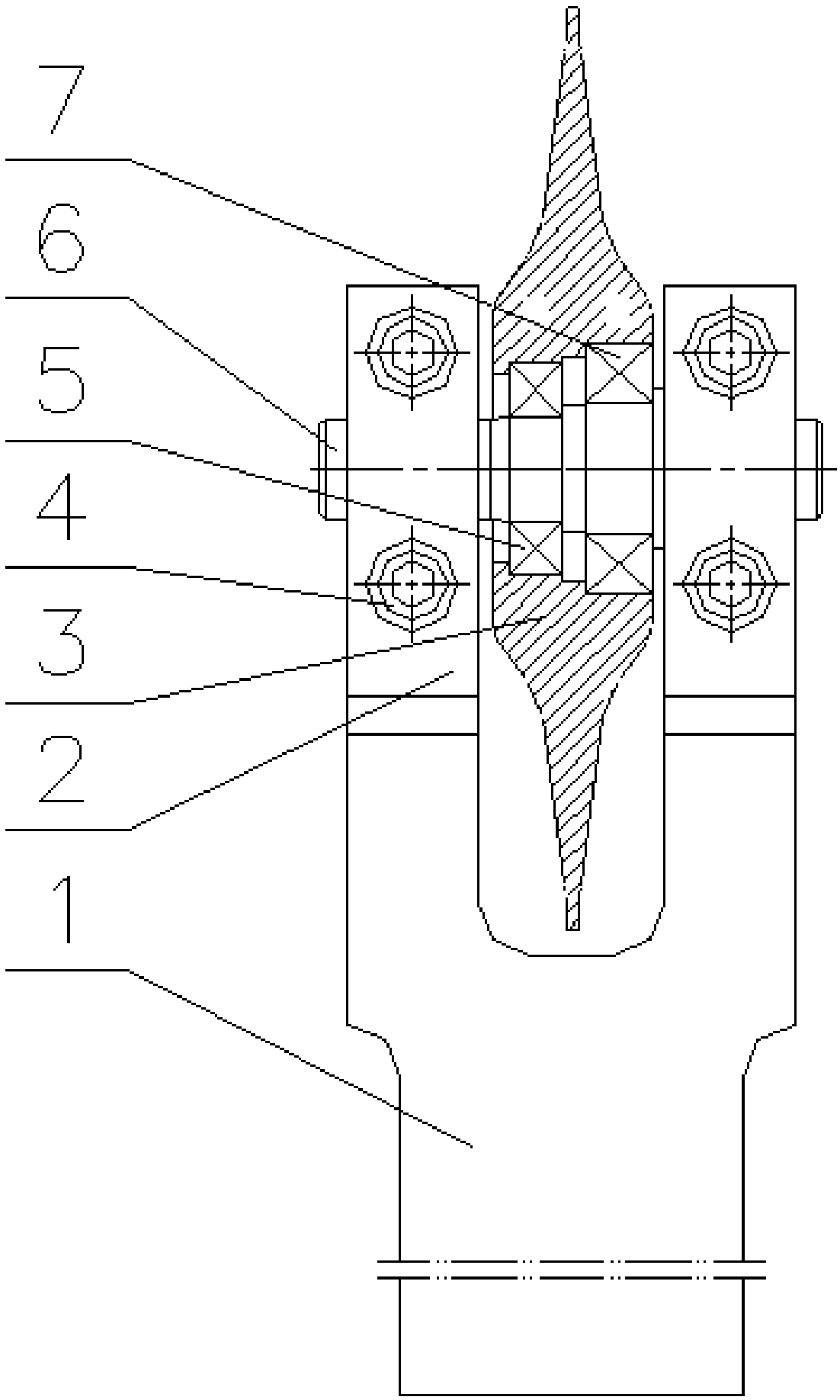

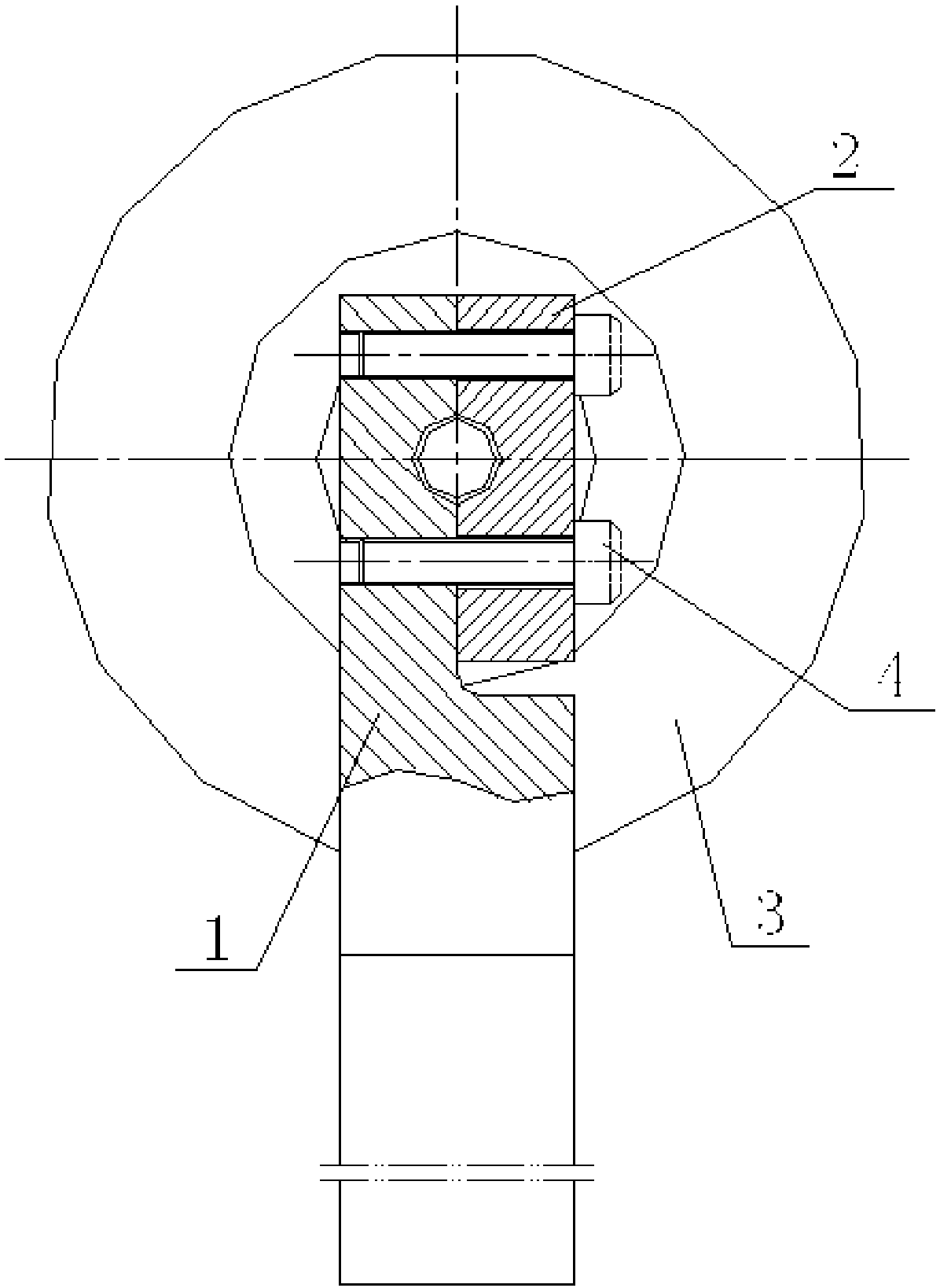

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be described in further detail:

[0016] Embodiments of the invention:

[0017] According to the rolling strengthening method of the annular groove of the bolt shank of the present invention, when the surface of the annular groove of the bolt shank in the prior art is subjected to rolling strengthening treatment, a lathe is used to carry out the rolling strengthening treatment on it, and the adopted The lathe is an ordinary lathe in the prior art. One end of the bolt that needs to be rolled and strengthened is clamped on the chuck of the lathe, and the other end is tightened with the top of the lathe, and then installed on the tool rest of the lathe. A rolling strengthening device for a lathe of the present invention is provided with a roller that can be pressed on the annular groove of the bolt shank on the rolling strengthening device for the lathe. After the strengthened annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com