Integrated type high-power LED lamp

A LED lamp, high-power technology, applied in cooling/heating devices of lighting devices, lighting and heating equipment, semiconductor devices of light-emitting elements, etc., can solve problems such as high heating power, short life, and difficulty in meeting heat dissipation requirements, and achieve The light projection angle is adjustable, the service life is improved, and the structure of the device is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

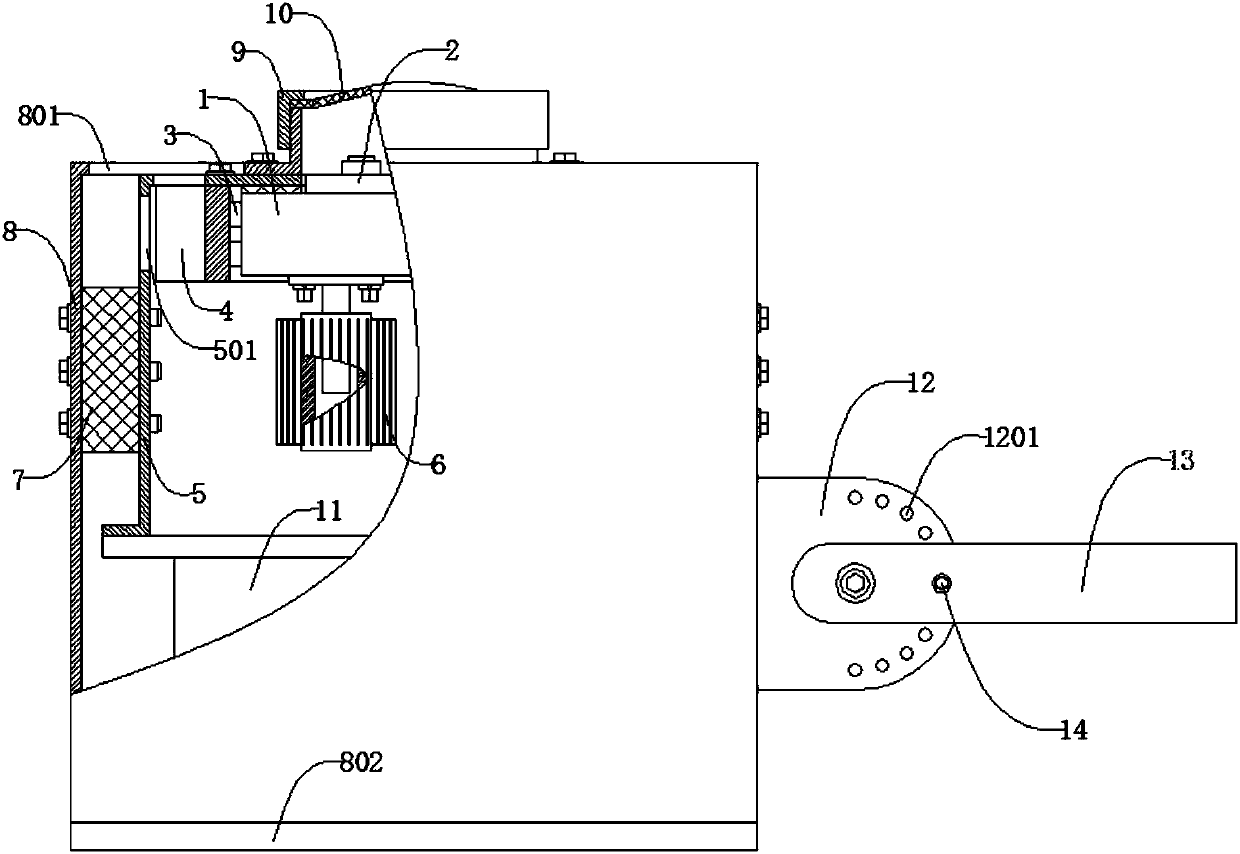

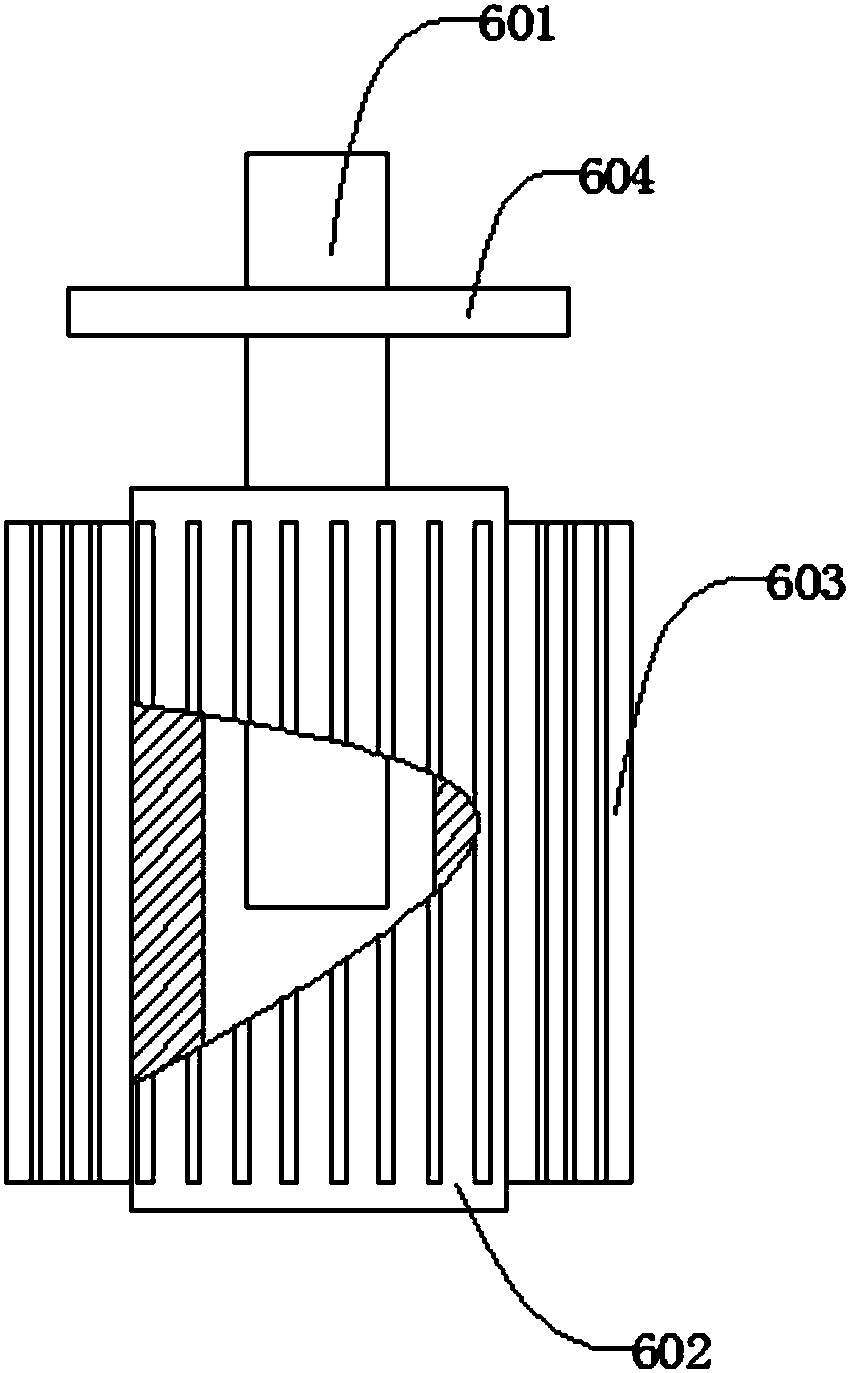

[0027] Such as figure 1 , figure 2 As shown, an integrated high-power LED lamp includes a circular radiator 1, an LED light-emitting module 2, a first heat pipe 3 and an annular radiator 4 uniformly distributed along the circular radiator 1 in a number not less than 2 , Inner shell 5, water cooling assembly 6, support ring 7, outer shell 8, gland 9, lens cover 10, fan 11, adjusting seat 12, bracket 13, adjusting pin 14, the LED light-emitting module 2 is located in a circular shape At the upper end of the radiator 1, the LED light-emitting module 2 is threadedly connected to the circular radiator 1, one end of the first heat pipe 3 extends into the circular radiator 1, and the first heat pipe 3 is connected to the circular radiator 1. 1 is tightly connected, the other end of the first heat pipe 3 extends into the annular radiator 4, the annular radiator 4 is tightly connected with the first heat pipe 3, and the inner shell 5 is located in the annular radiator 4 The outer side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com