Rubber heat conduction protecting layer for charger plug

A charger and protective layer technology, applied in the field of rubber heat-conducting protective layer for charger plugs, can solve problems such as damage to electronic components and difficult heat dissipation of the protective layer, and achieve the effects of uniform crosslinking density, good air permeability, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

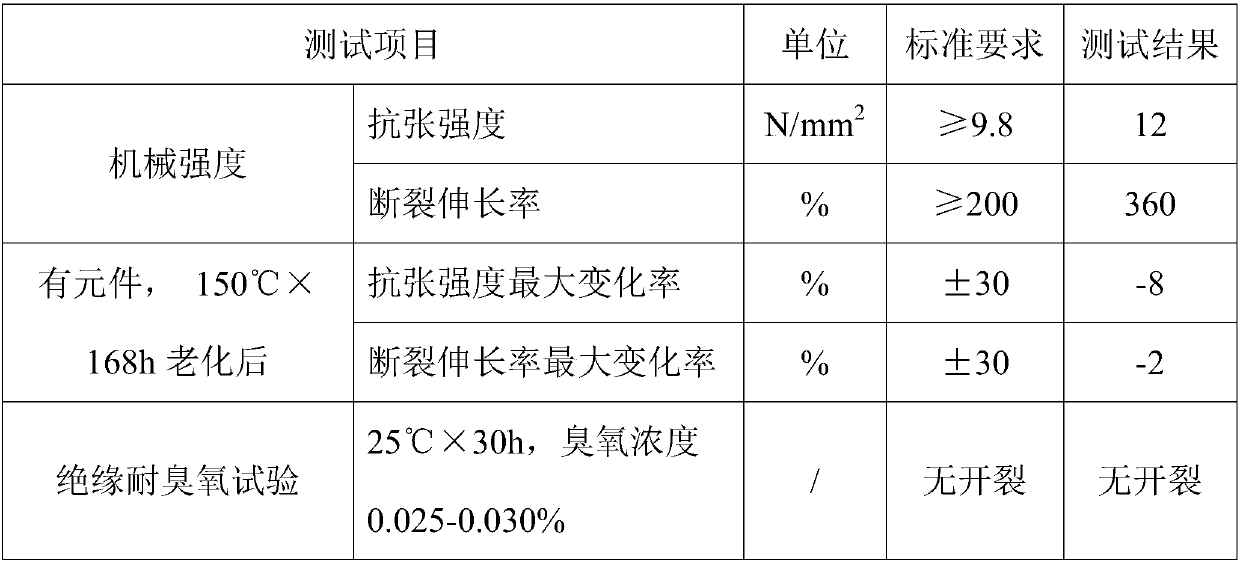

Examples

Embodiment 1

[0015] A rubber heat-conducting protective layer for a charger plug, the raw materials of which include: 110g of main ingredients, 1.6g of 1,3-bis(tert-butylperoxyisopropyl)benzene, 0.5g of dicumyl peroxide, and vulcanization accelerator CZ 0.8g, vulcanization accelerator TMTD 0.4g, filler reinforcing agent 85g, C9 petroleum resin 2g, hydroxyl silicone oil 1.5g, microcrystalline paraffin 1g, epoxy soybean oil 2g, polyvinyl alcohol 1g, melamine phosphate 4g, antioxidant 1g .

[0016] The main ingredients include: 120g of nitrile silicone rubber, 3g of poly-p-phenylene terephthalamide, and 10g of polystyrene. The filling reinforcing agent includes: 4g of cellulose composite, 35g of aluminum borate whiskers, and 40g of diatomaceous earth.

[0017] The cellulose composite is prepared by the following process: mix 40g ethyl cellulose, 1g formamide, and 105g acetone, heat up to 85°C and stir for 12min at a stirring speed of 1200r / min, add 4g epoxidized soybean oil, 4g carbon nanotu...

Embodiment 2

[0019] A rubber heat-conducting protective layer for a charger plug, the raw materials of which include: 120 g of main ingredients, 1 g of 1,3-bis(tert-butylperoxyisopropyl)benzene, 1.2 g of dicumyl peroxide, and vulcanization accelerator CZ 0.1 g, vulcanization accelerator TMTD 1g, filling reinforcing agent 75g, C9 petroleum resin 8g, hydroxyl silicone oil 0.5g, microcrystalline paraffin 2g, epoxy soybean oil 1g, polyvinyl alcohol 2g, melamine phosphate 1g, anti-aging agent 2g.

[0020] The main ingredients include: 80g of nitrile silicone rubber, 15g of poly-p-phenylene terephthalamide, and 4g of polystyrene. The filling reinforcing agent includes: 8g of cellulose compound, 15g of aluminum borate whisker, and 60g of diatomaceous earth.

[0021] The cellulose composite is prepared by the following process: mix 20g ethyl cellulose, 2g formamide, and 80g acetone, heat up to 95°C and stir for 5 minutes at a stirring speed of 1400r / min, add 2g epoxidized soybean oil, 12g carbon n...

Embodiment 3

[0023] A rubber heat-conducting protective layer for a charger plug, and its raw materials include: 112kg of main ingredients, 1.4kg of 1,3-bis(tert-butylperoxyisopropyl)benzene, 0.6kg of dicumyl peroxide, and vulcanization accelerator CZ 0.6kg, vulcanization accelerator TMTD 0.6kg, filling reinforcing agent 82kg, C9 petroleum resin 4kg, hydroxyl silicone oil 1.2kg, microcrystalline paraffin 1.2kg, epoxy soybean oil 1.7kg, polyvinyl alcohol 1.2kg, melamine phosphate 3kg, Anti-aging agent 1.2kg.

[0024] The main materials include: 110kg of nitrile silicone rubber, 6kg of poly-p-phenylene terephthalamide, and 8kg of polystyrene. Filling and reinforcing agents include: 5kg of cellulose composite, 30kg of aluminum borate whiskers, and 45kg of diatomaceous earth.

[0025] The cellulose composite is prepared by the following process: mix 35kg ethyl cellulose, 1.2kg formamide, and 100kg acetone, heat up to 88°C and stir for 10 minutes at a stirring speed of 1250r / min, add 3.5kg epo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com