Automatic shipping and distribution system from ferrite ring magnet sintering process to grinding process

A ferrite ring, sintering process technology, applied in the direction of grinding feed motion, machine tools suitable for grinding workpiece edges, grinding machine parts, etc. It can improve production efficiency and product qualification rate, reduce intermediate inventory, and avoid bumps and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

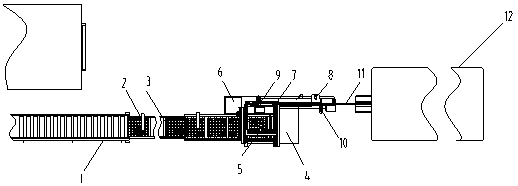

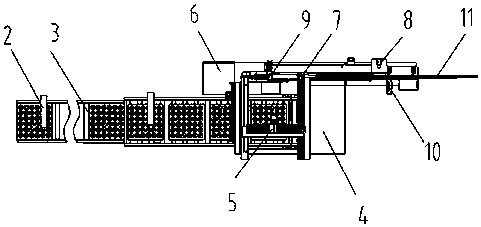

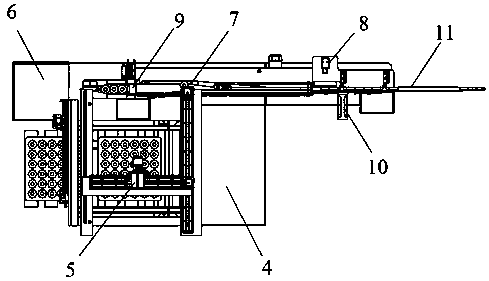

[0019] refer to figure 1 , 2 , 3. This embodiment includes a sintered grinding track 1 , an automatic shipping distribution device and a grinding machine 12 , the sintered grinding track 1 is connected to the automatic shipping distribution device, and the automatic shipping distribution device is connected to the grinding machine 12 .

[0020] The automatic shipment and distribution device includes front-end conveying track 3, lifting platform 4, manipulator 5, transfer table 6, turning mechanism 7, ring magnetic positive and negative visual recognition device 8, lamination removal device 9, reverse sheet removal collection device 10, and rear The end conveying track 11; the sintering and grinding track 1 is connected with the front end conveying track 3, the inlet of the front end conveying track 3 is provided with a ring magnetism detector 2, and the discharge port of the front end conveying track 3 is connected with the inlet of the rear end conveying track 11. The materi...

Embodiment 2

[0028] refer to Figure 7, this embodiment includes a first sintered grinding track 1-1, a second sintered grinding track 1-2, a first automatic shipment distribution device, a second automatic shipment distribution device, a third automatic shipment distribution device, a fourth automatic shipment distribution device Distribution device, fifth automatic shipment distribution device, sixth automatic shipment distribution device, first connecting track 13-1, second connecting track 13-2, first grinding machine 12-1, second grinding machine 12-2, third grinding machine 12-3, the fourth grinding machine 12-4, the fifth grinding machine 12-5 and the sixth grinding machine 12-6, the first sintering grinding track 1-1 is connected with the first automatic shipment distribution device, the second sintering grinding track 1 -2 connected with the fifth automatic shipment distribution device, the first automatic shipment distribution device, the second automatic shipment distribution de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com