Blast furnace smelting method capable of lowering coke ratio and increasing coal ratio

A technology of blast furnace smelting and coal ratio, which is applied in the direction of blast furnace, blast furnace details, furnace, etc., can solve the problems of poor effect and poor coke ratio effect, and achieve the effect of easy promotion, reduction of coke ratio and increase of coal ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation of vanadium-titanium sintered ore treated with preparation: sinter inhibitor and water are mixed according to the mass ratio of 4:100 and then sprayed onto the surface of vanadium-titanium sintered ore to obtain vanadium-titanium sintered ore treated with sintering ore inhibitor; In total, the sinter inhibitor components include: calcium chloride 70%, magnesium chloride 12%, borax 10%, bromine 3%, penetrant 5%; the penetrant is fatty alcohol polyoxyethylene ether;

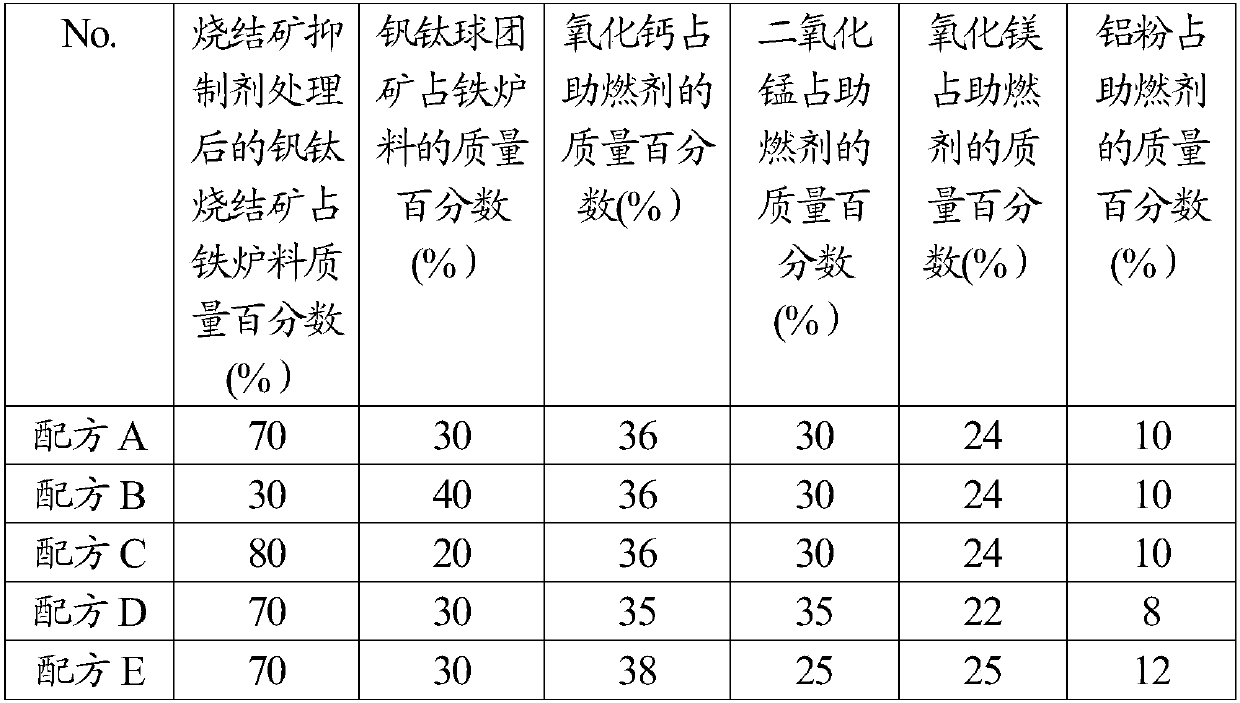

[0041] Optional iron charge and combustion aid: the formula is shown in Table 1; wherein, in terms of mass percentage, the mass fraction of active aluminum in the aluminum powder is not less than 98%.

[0042] According to Table 1, choose iron charge and combustion aid

[0043] Table 1

[0044]

Embodiment 2~16

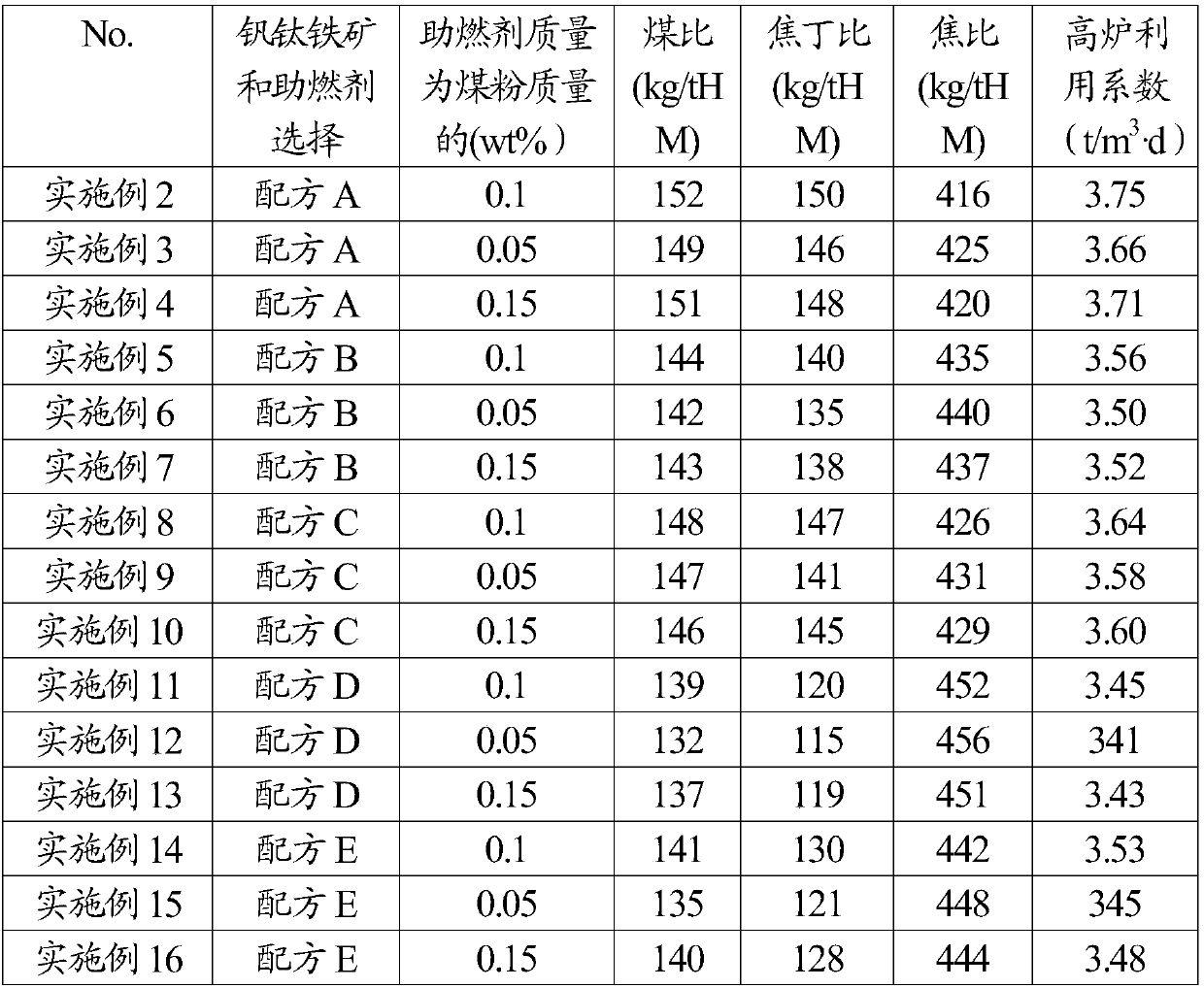

[0046] Add diced coke to the iron charge of A~C, mix uniformly to form ore layers; alternately distribute coke and the ore layers into the blast furnace to form an alternate layered structure of the ore layers and the coke layers; Mix with pulverized coal to obtain a mixture; the mixture is expressed as N 2 As a transport medium, it is injected into the blast furnace for combustion; wherein, the particle size of the combustion accelerant is greater than 95% of those with a diameter of 0.015mm or less, and the particle size of the pulverized coal is 150-180 mesh

[0047]Control blast temperature to 1150~1250℃, oxygen enrichment>2500m 3 / h, make iron under the conditions shown in Table 2, calculate the iron content in the slag and the utilization coefficient of the blast furnace, and see Table 2 for the results.

[0048] Table 2

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com