Method for regenerating spent hydrogenation catalyst

A waste hydrogenation catalyst and catalyst technology, which is applied in the direction of catalyst regeneration/reactivation, catalyst carrier, molecular sieve catalyst, etc., can solve the problems of incomplete metal recovery, secondary pollution, waste of oil, etc., to achieve compound utilization and avoid Effect of clogging micropores and improving catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

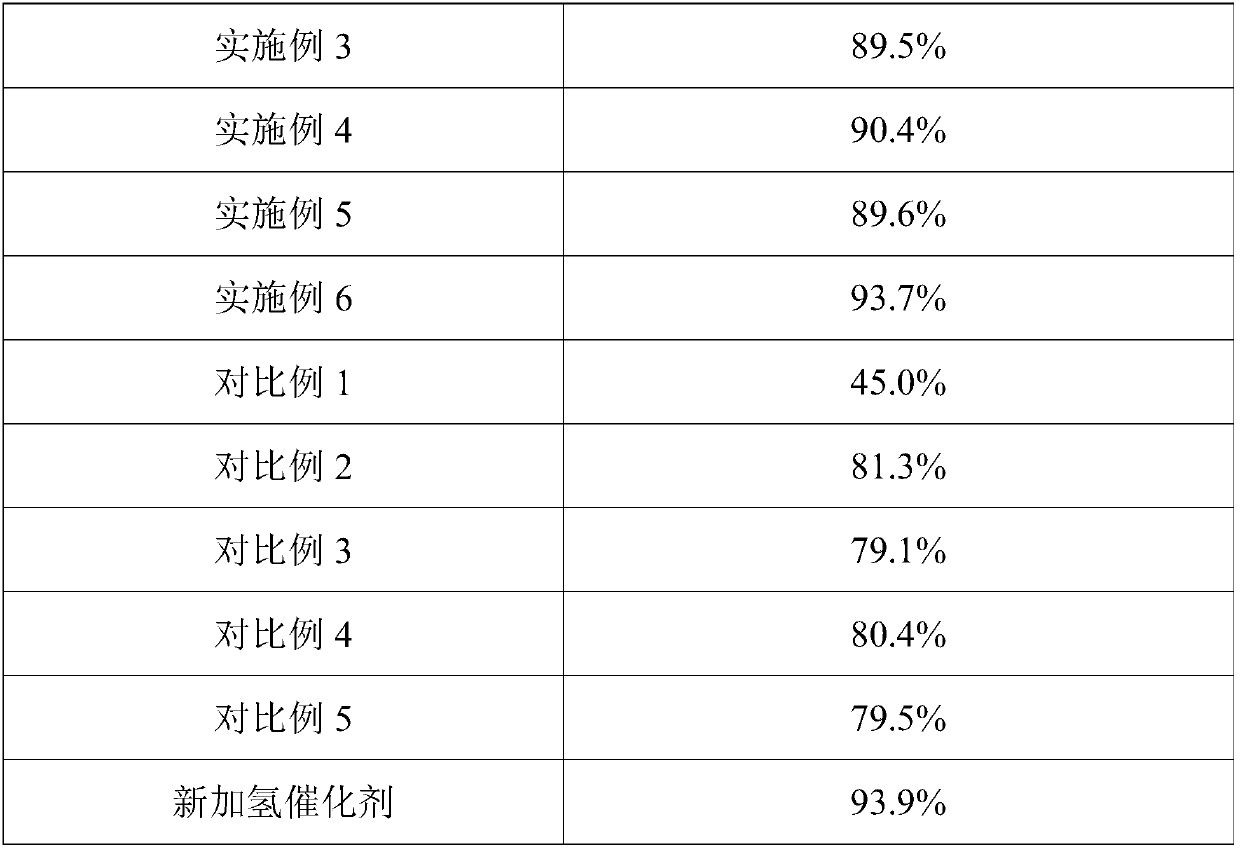

Embodiment 1

[0034] A method for regenerating a spent hydrogenation catalyst provided in this embodiment includes the following steps:

[0035] S1. Under the action of the suspended bed hydrogenation catalyst, after the heavy oil raw material-high temperature coal tar is subjected to the suspended bed hydrogenation process, the mixture of the waste catalyst and heavy oil discharged from the bottom of the vacuum tower adopts automatic backflushing The washed filter is subjected to solid-liquid separation to obtain a filter cake, that is, a spent hydrogenation catalyst;

[0036] S2. Dry distillation of the waste hydrogenation catalyst at 600° C. for 2.2 hours to obtain catalyst A and dry distillation gas after dehydration and deoiling, and then dedust the dry distillation gas. The dry distillation gas is cooled to obtain high-boiling oil and water mixture and flammable low-boiling gas. The high-boiling oil and water mixture is separated from oil and water to obtain crude oil and oily wastewa...

Embodiment 2

[0040] A method for regenerating a spent hydrogenation catalyst provided in this embodiment includes the following steps:

[0041]S1. Under the action of the suspended bed hydrogenation catalyst, after the heavy oil raw material-atmospheric residual oil is subjected to the suspended bed hydrogenation process, the mixture of the waste catalyst and the heavy oil product discharged from the bottom of the vacuum tower adopts a plate frame The filter performs solid-liquid separation to obtain a filter residue, that is, a waste hydrogenation catalyst;

[0042] S2. Dry distillation of the waste hydrogenation catalyst at 700° C. for 2.1 h to obtain dehydration and deoiled catalyst A and dry distillation gas, then dedust the dry distillation gas, mix the obtained dust with catalyst A, and dedust the dedusted gas. The dry distillation gas is cooled to obtain high-boiling oil and water mixture and flammable low-boiling gas. The high-boiling oil and water mixture is separated from oil and...

Embodiment 3

[0046] A method for regenerating a spent hydrogenation catalyst provided in this embodiment includes the following steps:

[0047] S1. Under the action of the suspended bed hydrogenation catalyst, after the mixture of heavy oil raw material - medium and low temperature coal tar and pitch is subjected to the suspended bed hydrogenation process, the waste catalyst discharged from the bottom of the vacuum tower and the heavy oil product are mixed The liquid is centrifuged by a centrifugal separator to obtain solid slag, that is, a waste hydrogenation catalyst;

[0048] S2. Dry distillation of the waste hydrogenation catalyst at 400° C. for 2.5 hours to obtain catalyst A and dry distillation gas after dehydration and deoiling, and then dedust the dry distillation gas. The dry distillation gas is cooled to obtain high-boiling oil and water mixture and flammable low-boiling gas. The high-boiling oil and water mixture is separated from oil and water to obtain crude oil and oily waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com